Originally posted by TechAUmNu

View Post

Announcement

Collapse

No announcement yet.

Team Coolspeedbot: first feather weight robot

Collapse

X

-

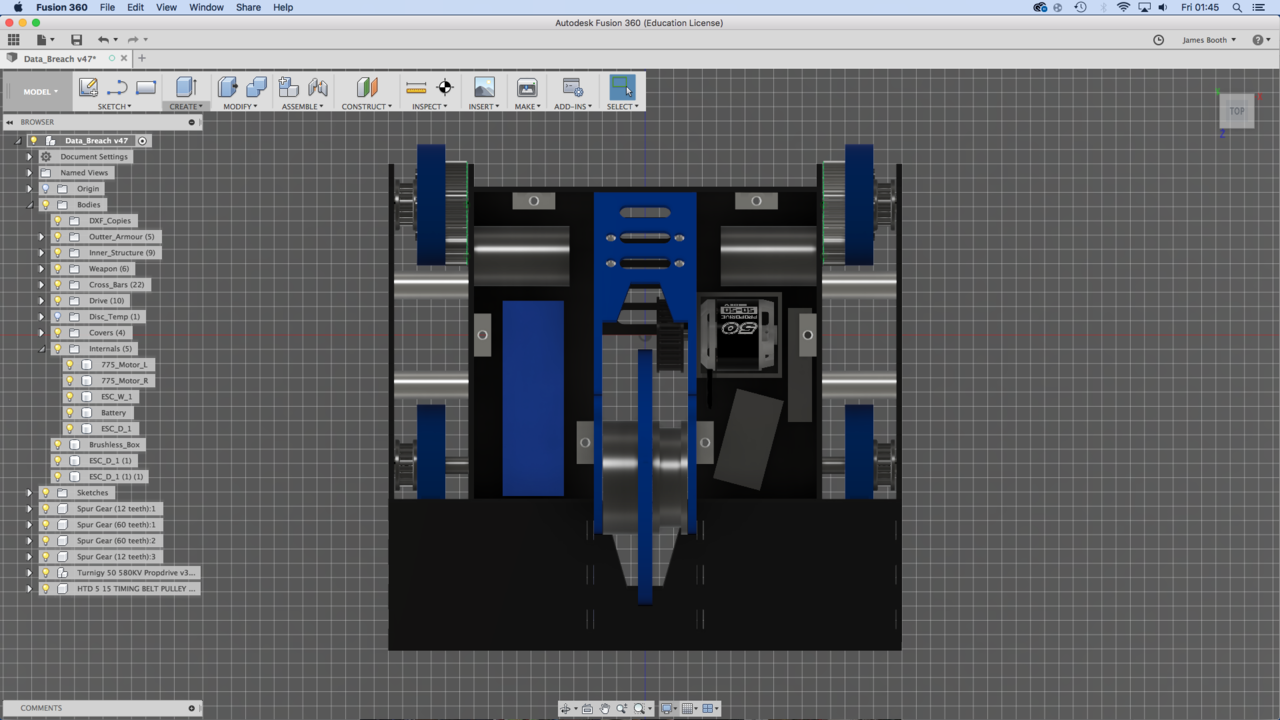

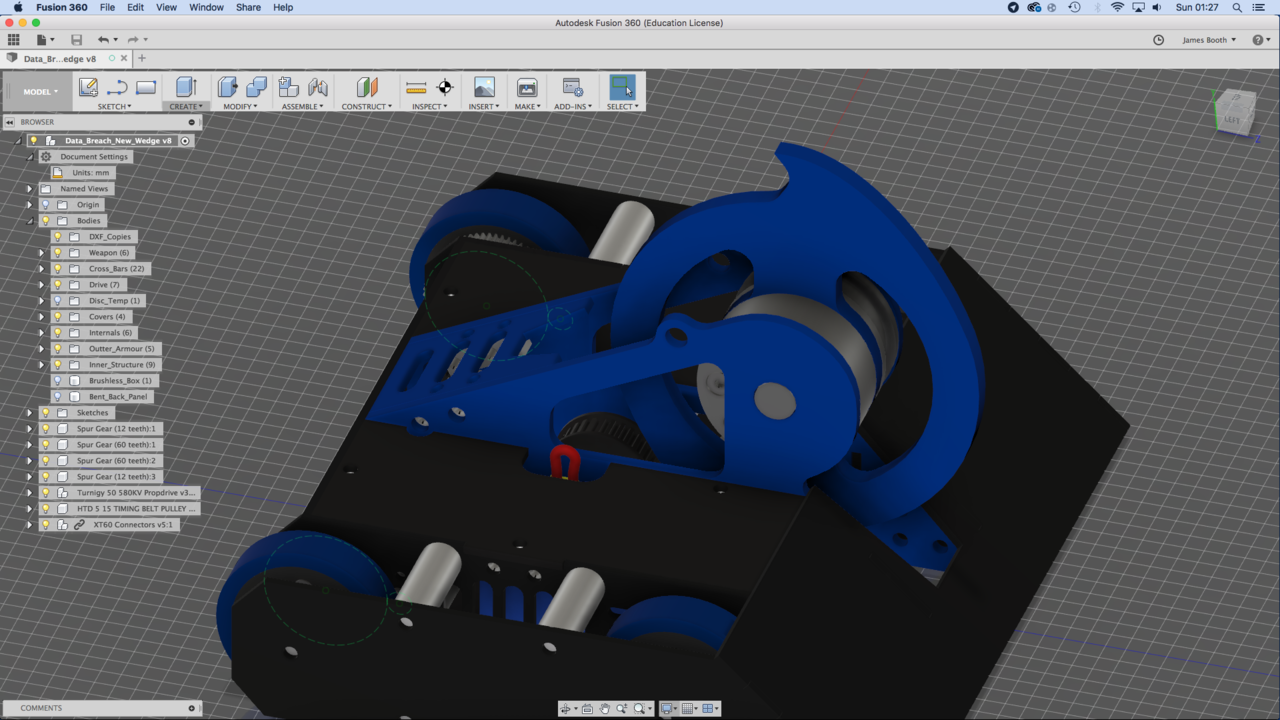

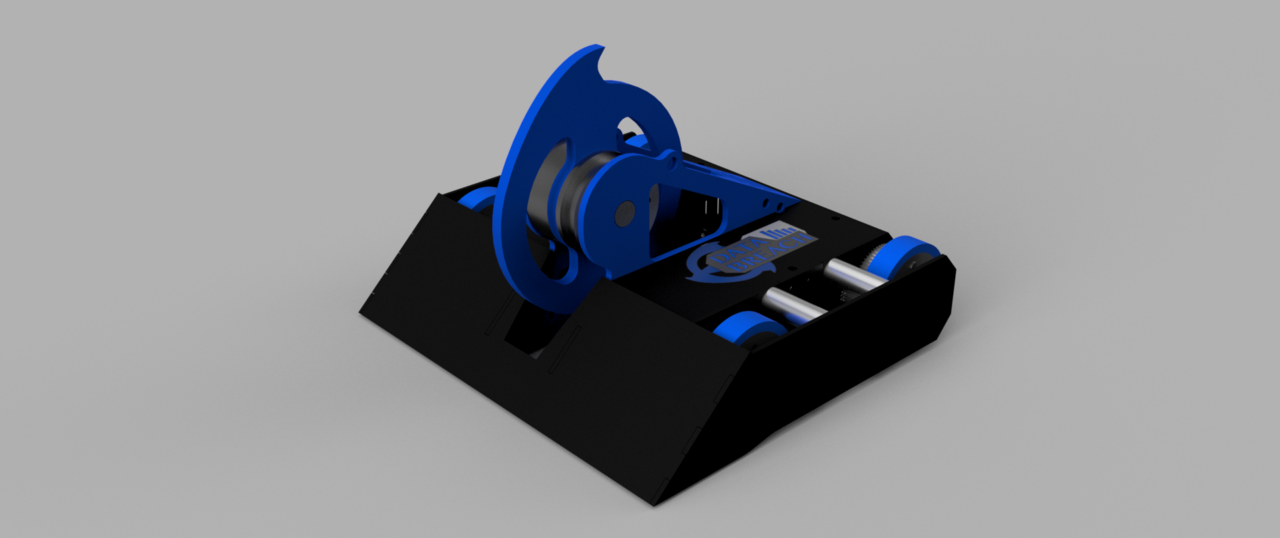

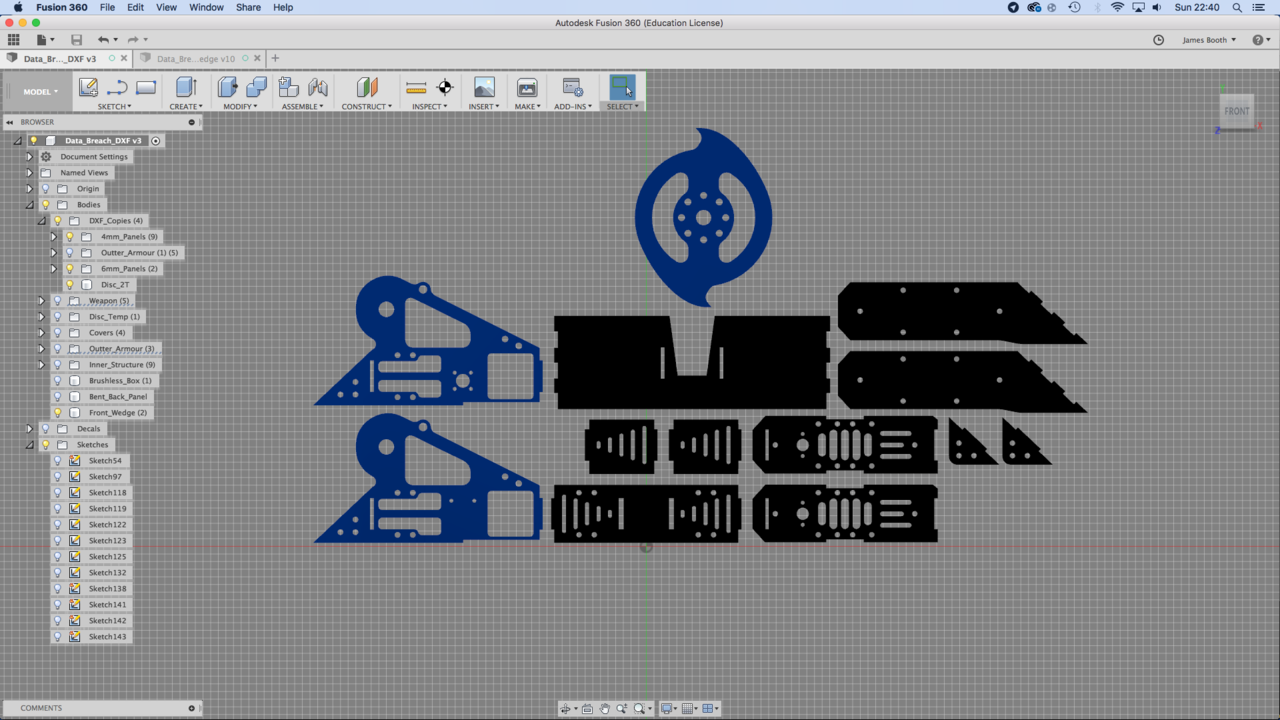

More CAD updates.

So I’ve started adding weight saving holes and added the threaded bars to hold the top and bottom panels on what those panels will be made of is still to be decided.

A top down view showing how tight it is inside for the internals. The internals in question are: 2x 775 brushed motors, 6s 3300mah 30c lipo, a Prodrive 5060 360 kv brushless motor, the ESCs are based on the botbitz 85a ESCs and the weapon ESC is based on the turnigy plush 100a.

As I said the top covers and base plate material haven’t been decided yet as I don’t know what light material to use.

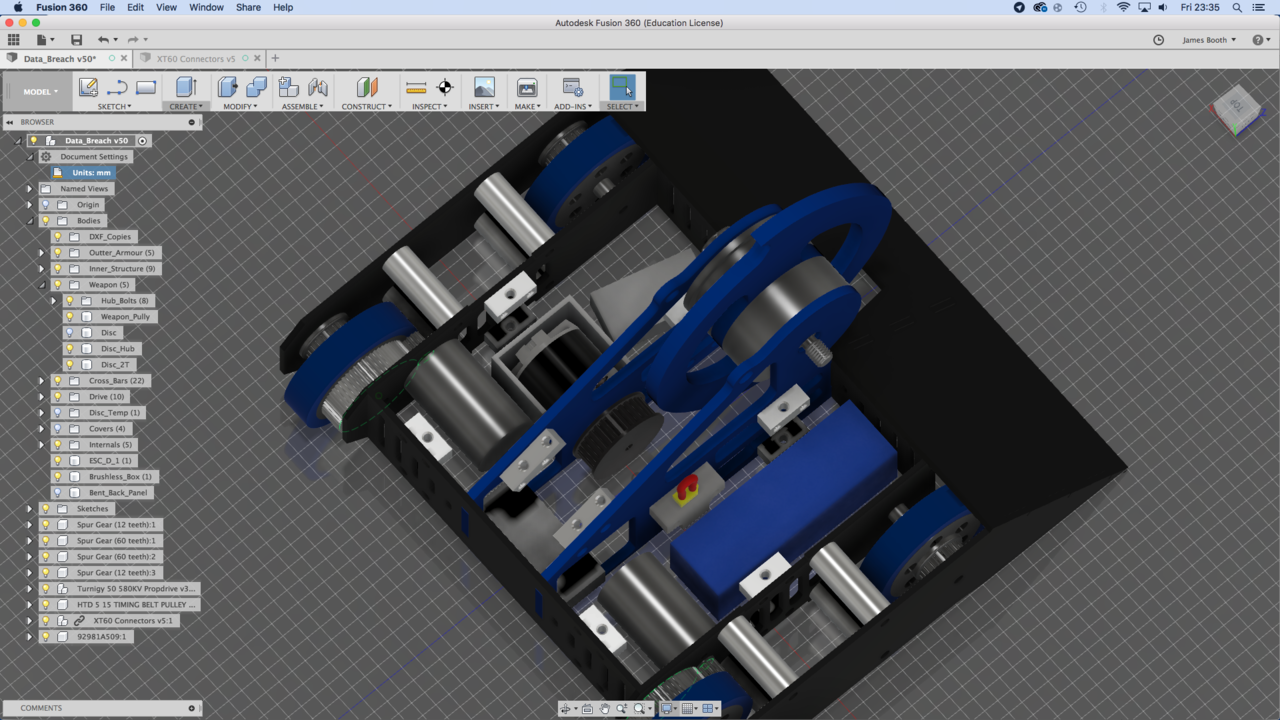

I’ve added the link block to the CAD and slightly hard to see but I’ve added a m12 shoulder bolt as the shaft for the weapon as I’ve seen it being used by other VSs and cause I’m trying to save weight where I can.

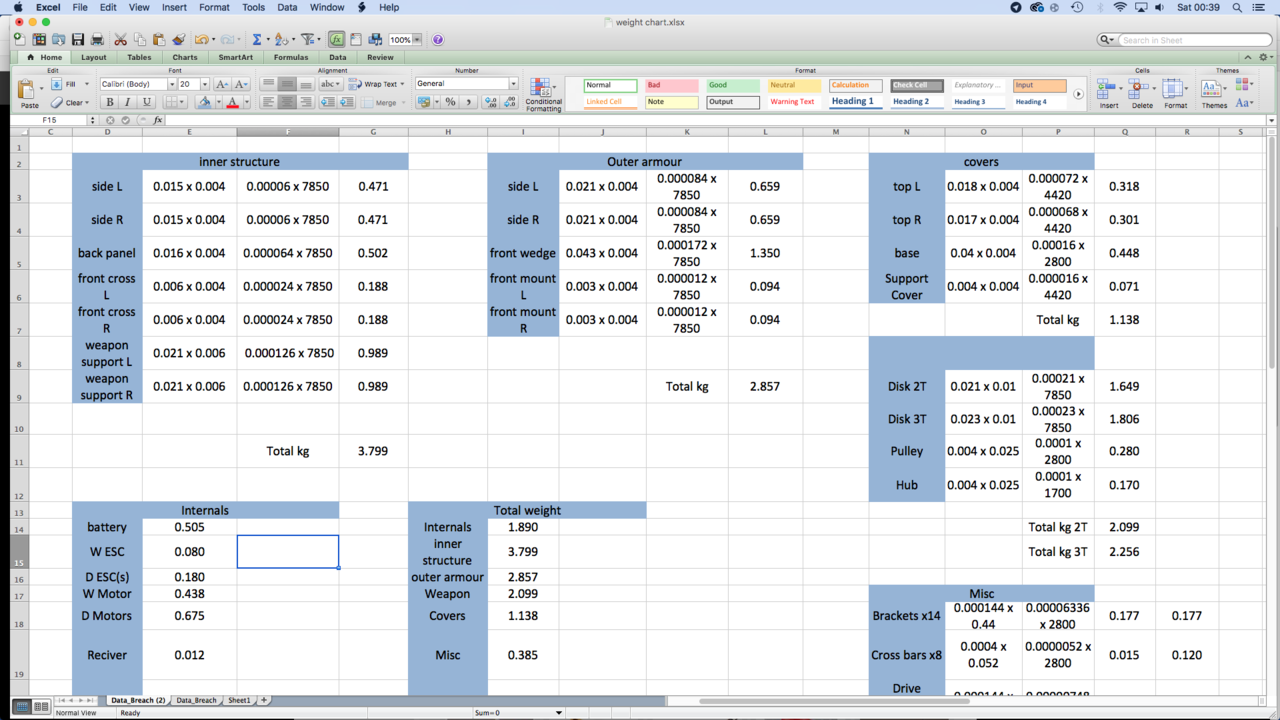

And speaking of weight saving here is the rough weight calculations. So far the approximate weight is roughly 12.2kg.

Also while I remember what would be the recommended ground clearance for arenas like the RoboChallange arena at the moment it's got a 5mm ground clearance, will that be enough or should I am for about 7.5mm-10mm?

Comment

-

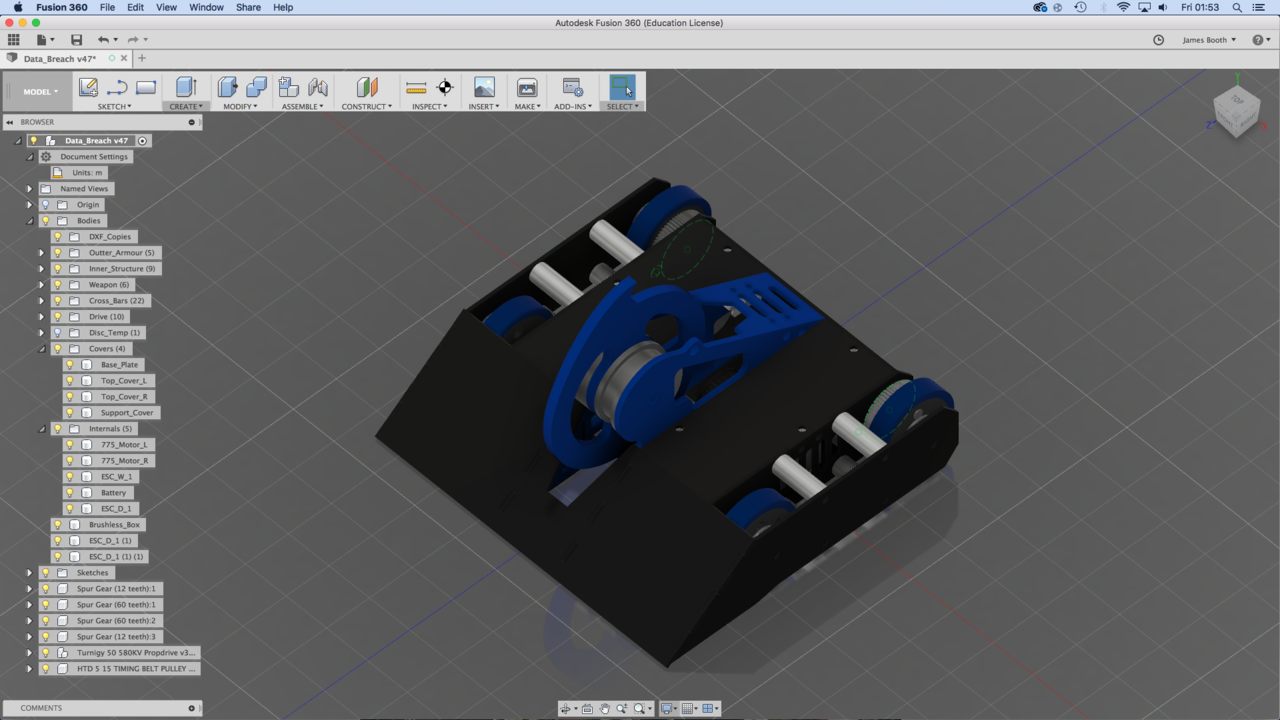

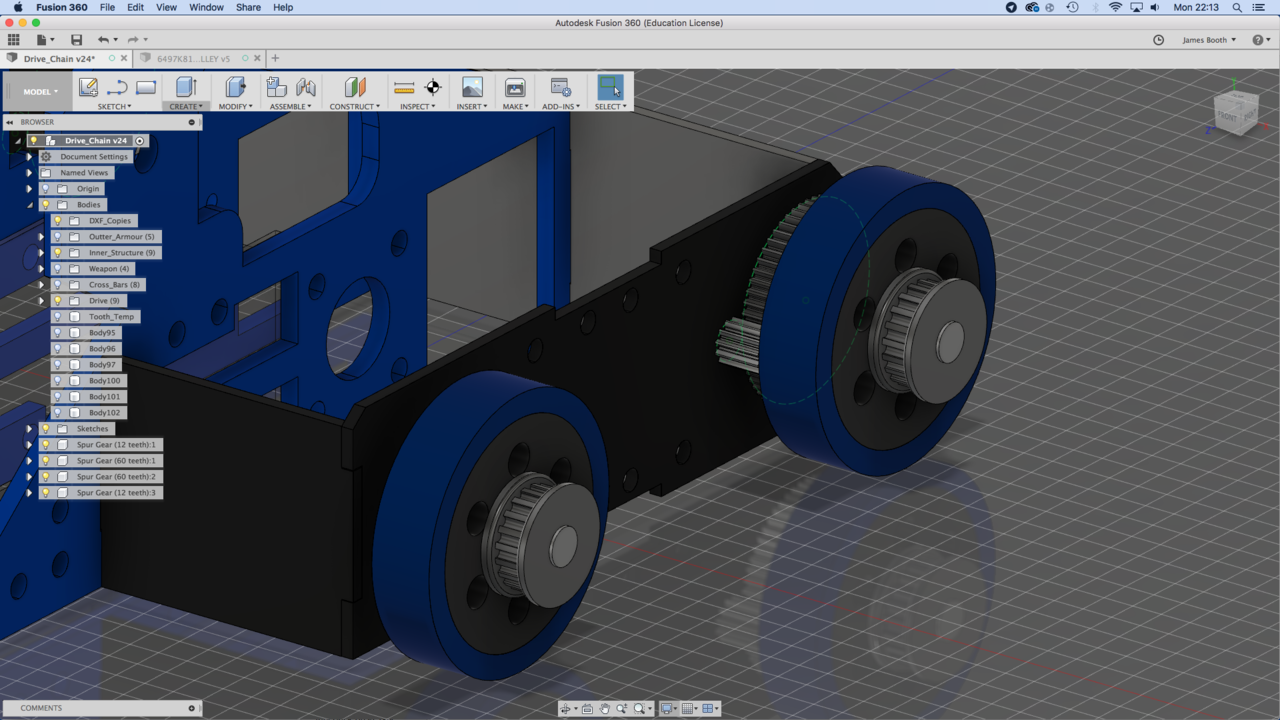

Even more CAD updates. I Shortened the wedge saving weight, plus I redid my maths and realised that Data-Breach can actually use a 20mm titanium dead shaft for the weapon.

Now I should ask, how much bigger should I make holes in 6mm and 10mm hardox for watercutting? So to minimise having to drill out the undersized holes. I've already been told about 4mm hardox.

Comment

-

I can't say much about slot and tab panels, but I've found that the dimensions on my watercut wedge/flipper are at max 0.7mm greater than I expected them to be. Most of the dimensions are about 0.5mm greater.

Also, yeah for smaller holes like 6mm, I would make them a bit larger. I would maybe go 6.5mm - 6.8mm? I can't say for sure, but I made all mine 6mm in my CAD and the bolts didn't quite fit.

A 10mm hole should be fine at its normal size - is this for a bolt or a rod?

CAD is looking very nice!

Comment

-

Yeah all my holes for waterjet are 1mm bigger than required so they are a good clearance fit. The tolerance is caused by the kerf of 0.5-0.7mm for 4mm thick steel. If its thicker you might need more clearance. If they are too small you just ruin a bunch of bolts. Small holes tend to not be very round (<5mm).

Comment

-

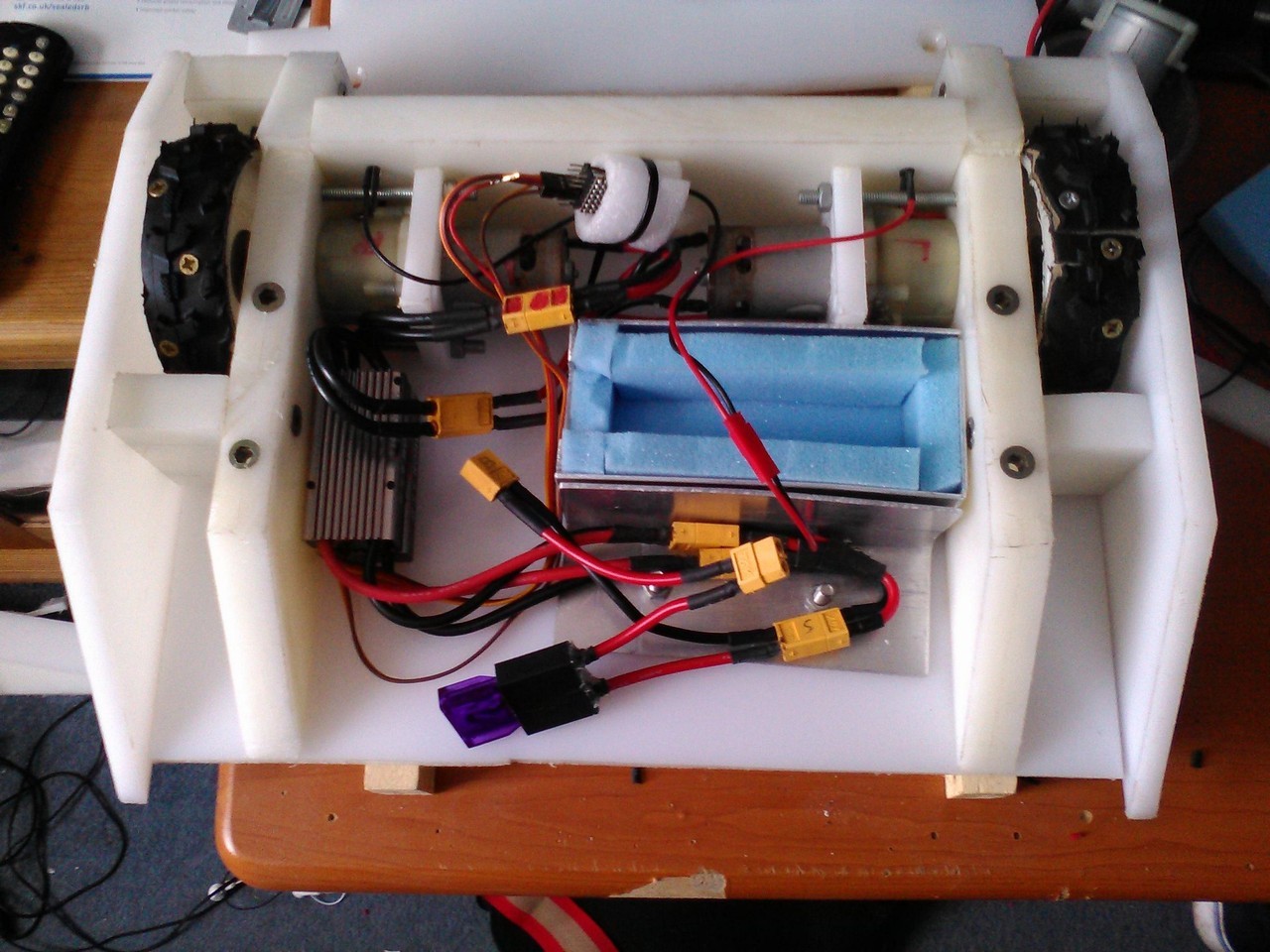

Wow it's been a while hasn't it. Time for a update, after finally getting a new job I was able to get funds for my robots and bought a load of parts for CSB, ranging from wires, connectors, aluminium sheet, foam and Lipo battery to name a few.

Earlier today I finally did a test run of the bot with it's new battery (and fuse) safely stored in it's aluminium box with foam padding.

I did a test outside just to make sure everything was fine before I came in and filmed a test inside. However as you'll see in the video the power lights started to play up, I later discovered my solder points had actually broken in places. I've bought a new soldering station to rectify the weak joints made by low temperatures of the old soldering iron which has decided to clap out a hour ago.

Comment

-

The robot is looking really good

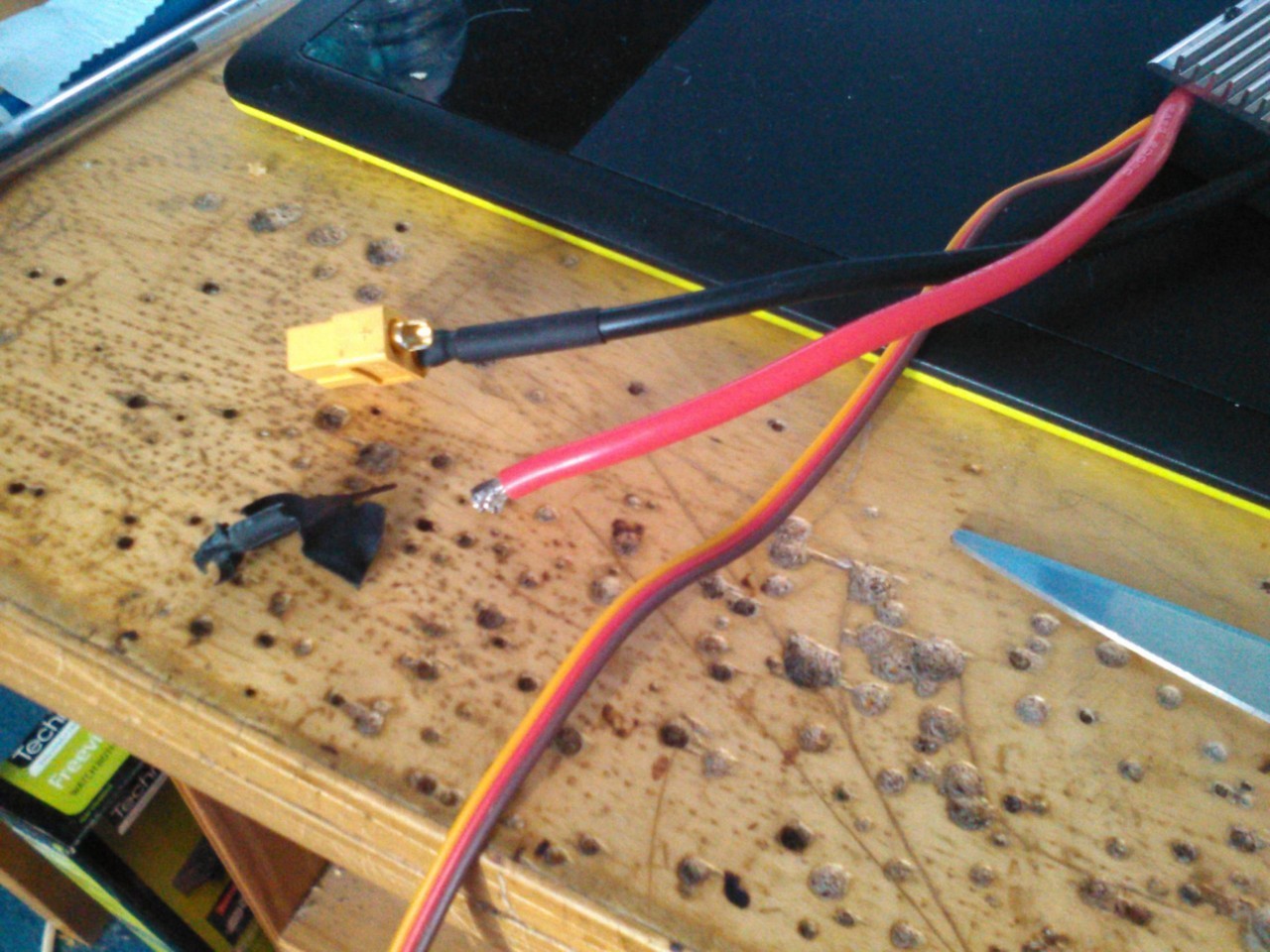

When you are soldering the XT60 on, remember to tin the connector first (put some solder on the connector and the wire), put some flux on the joint, then melt the solder you put on and let the wire slide into place.

this video is good: https://www.youtube.com/watch?v=mH32jwFc8Js

Sorry if you knew this already, this is just something I found useful to know.

Comment

Comment