Any chance of getting a refund on the drill?The disk doesn't look that big and chances are that you will find various frame parts that won't fit either. More importantly, a bench drill that can't accommodate the disk probably doesn't have a motor powerful enough to run a 1" twist drill thru steel. My bench mill can only just do it and nowadays, I use a hole saw for anything over 3/4".

Announcement

Collapse

No announcement yet.

Wraith, the El Cheapo spinner

Collapse

X

-

Probably not much chance of that unfortunately, it seems fine for little jobs and the frame bits seem to fit as far as this robot goes. I may have another solution to getting the disc bored out it just sets me back slightly. I think the best thing to do is just to save up that extra bit and get something bigger eventually if it proves a real problem.

Comment

-

Shame about the disc being too big. One of those awkwardly unpredictable things. I have a cheap (£40) bog standard small pillar drill (350w?) and have used it for absolutely everything. My main complaint is accuracy and that the "bed" deflects terribly, so I stick wood under it.

Anyone with a large enough lathe or a mill would be able to take the bore out quite quickly. You could also specifically ask that they true the bore's position to the circumference of the disc.Last edited by Ellis; 9 August 2014, 09:15.

Comment

-

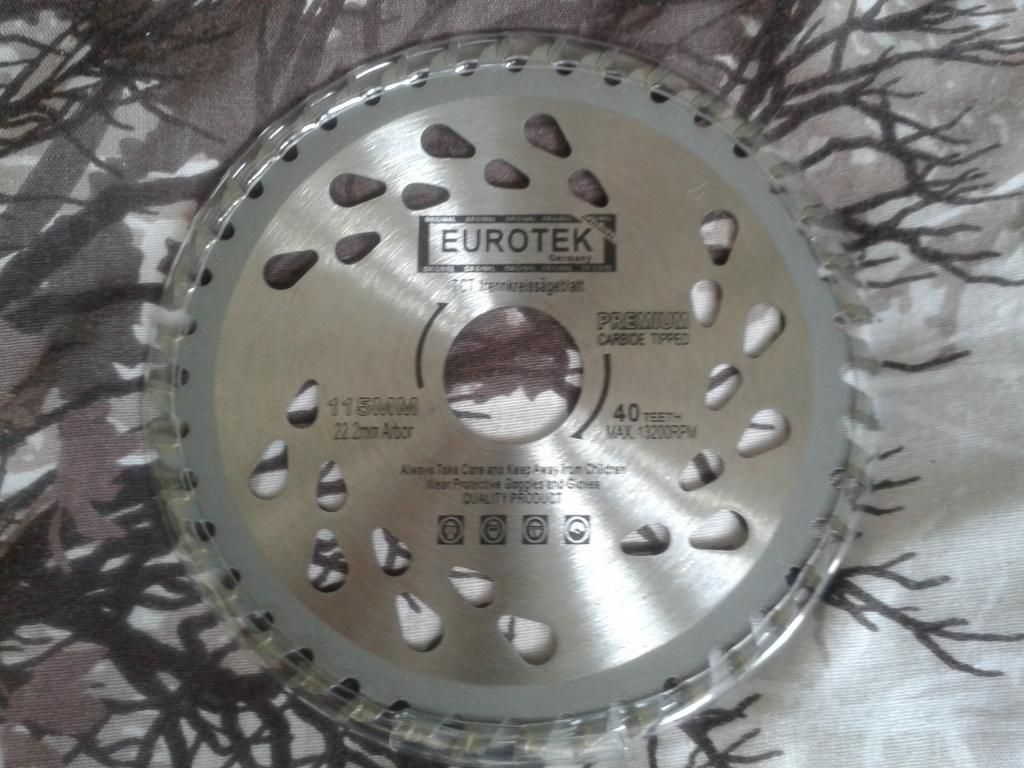

Tiny update, after my circular saw crapped out yesterday I was left with no way of cutting out the hdpe bulkheads and supports other than hand saws, today however I've found a solution that I'd forgot I had. It's a saw blade for an angle grinder that should allow me to cut everything with at least some precision if I take it slowly.

Comment

-

I would be particularly careful with cutting plastic - a grinder spins much faster than a circular saw and with a high tooth count blade, its likely to melt the plastic and grab. I found that the best blade for cutting PE plastics is a ripping blade with a low tooth count. The ease of cutting VS any type of cross-cut blade is amazing and they are also cheaper.

Comment

-

Putting the disc on the back burner for now and focusing on the bar weapon seeing as that will actually fit on my drill press. Brought a piece of 6082 (250 x 60 x 15mm) and I'll attach one of the huge steel teeth for the disc either end, should be a better weapon as more of the weight will be on the outside and I should be able to knock it up fairly quickly.

Comment

Comment