Announcement

Collapse

No announcement yet.

Team Coolspeedbot: first feather weight robot

Collapse

X

-

Ok need some advise on water cutting tolerances. Namely do I need to add x amount of mm to the outside of the part's outline to compensate for the width/ keft of the watercutter?

-

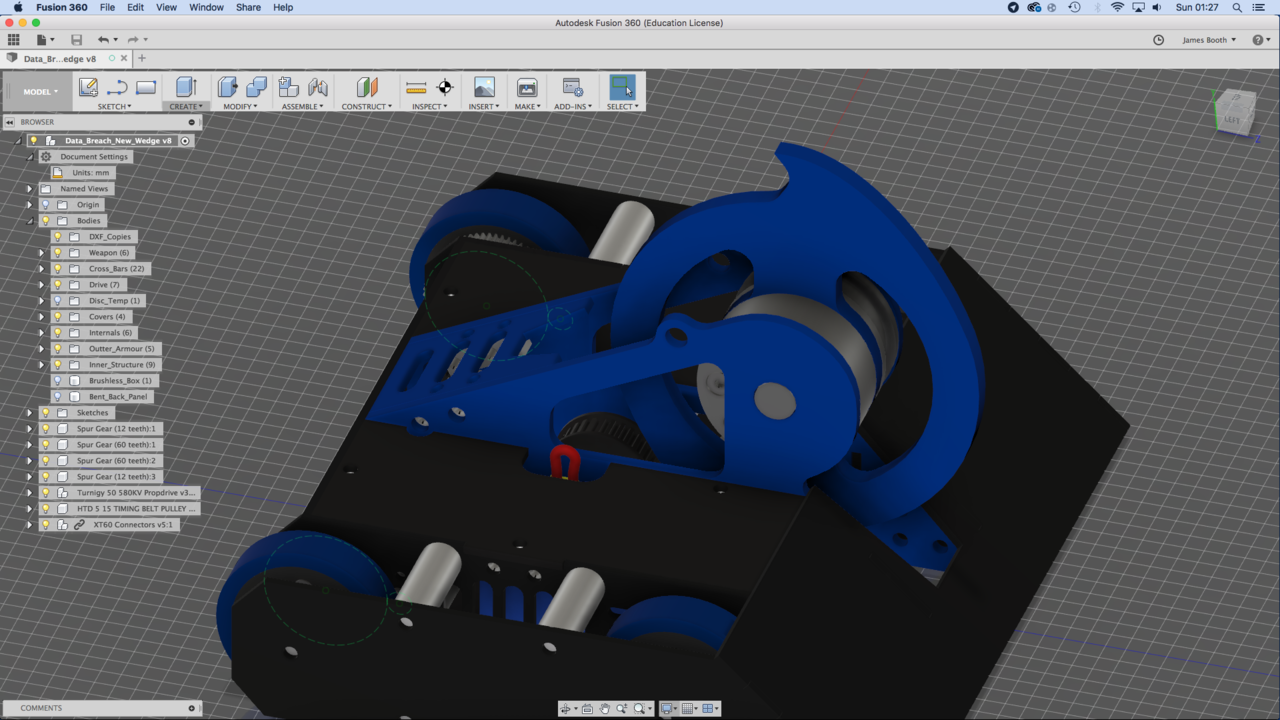

Even more CAD updates. I Shortened the wedge saving weight, plus I redid my maths and realised that Data-Breach can actually use a 20mm titanium dead shaft for the weapon.

Now I should ask, how much bigger should I make holes in 6mm and 10mm hardox for watercutting? So to minimise having to drill out the undersized holes. I've already been told about 4mm hardox.

Leave a comment:

-

Think the ground clearance would be OK at RobotChallenge and Extreme Robots, 10mm is quite high.

Leave a comment:

-

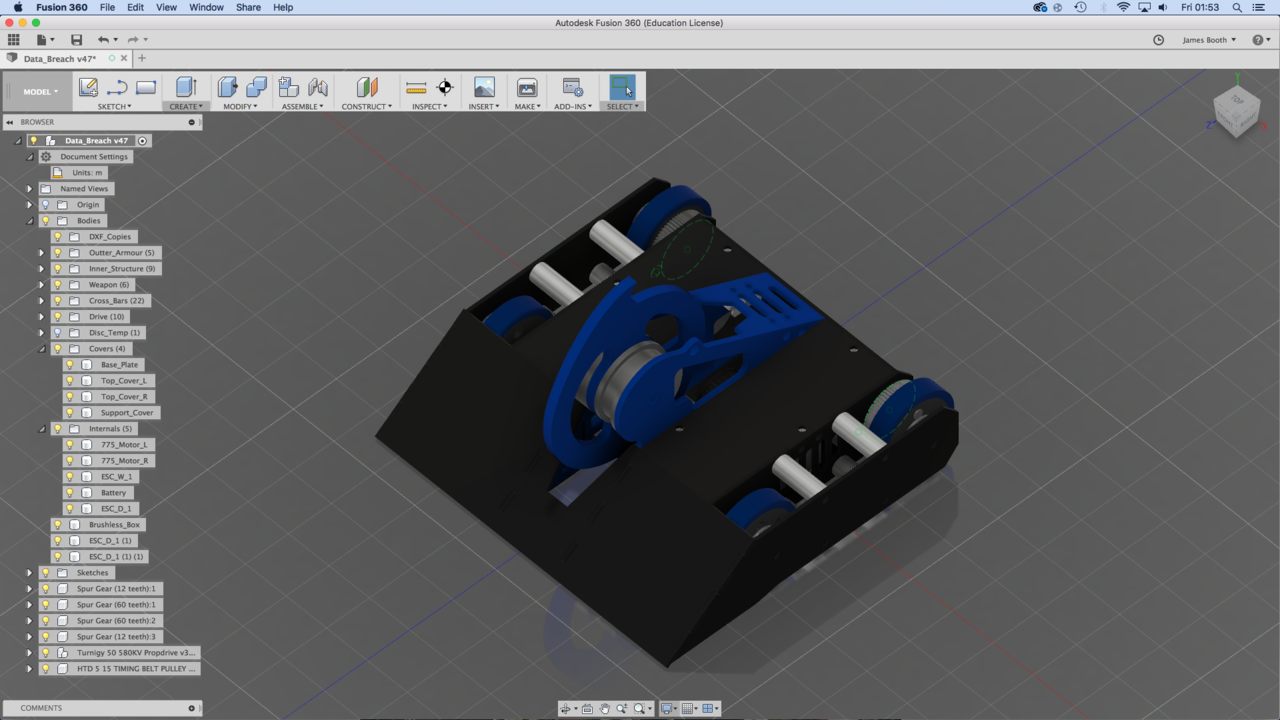

More CAD updates.

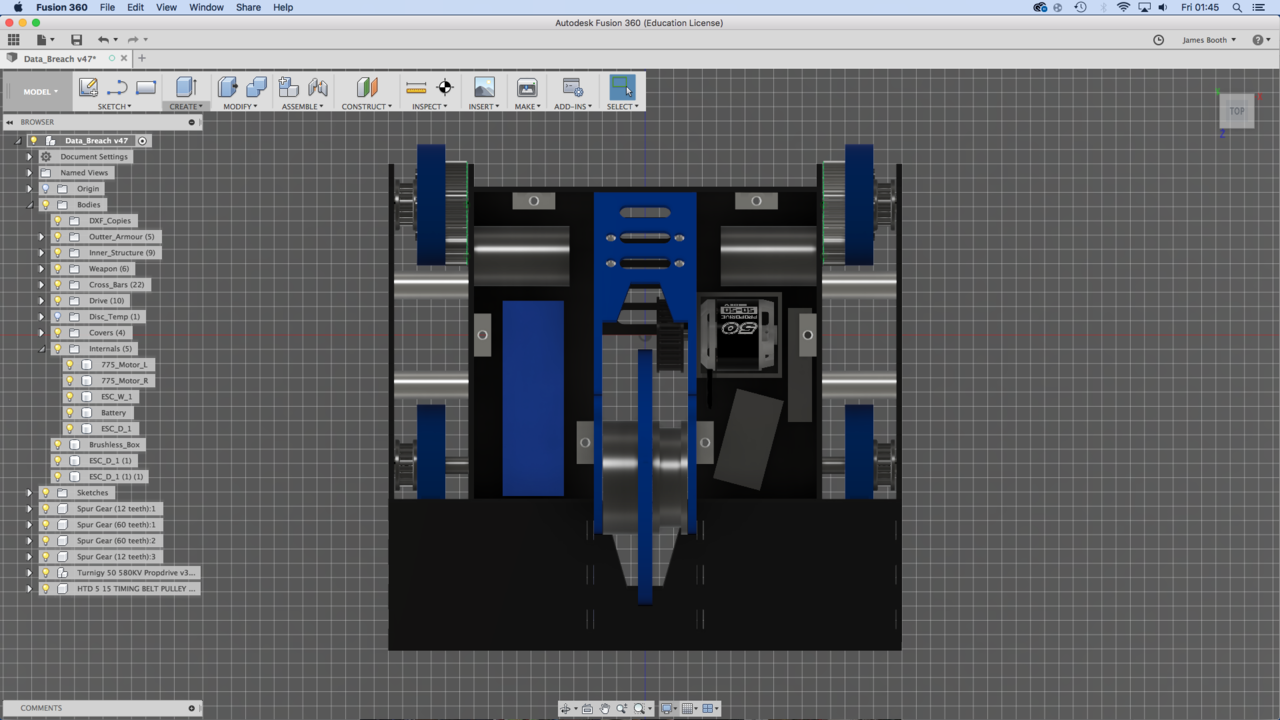

So I’ve started adding weight saving holes and added the threaded bars to hold the top and bottom panels on what those panels will be made of is still to be decided.

A top down view showing how tight it is inside for the internals. The internals in question are: 2x 775 brushed motors, 6s 3300mah 30c lipo, a Prodrive 5060 360 kv brushless motor, the ESCs are based on the botbitz 85a ESCs and the weapon ESC is based on the turnigy plush 100a.

As I said the top covers and base plate material haven’t been decided yet as I don’t know what light material to use.

I’ve added the link block to the CAD and slightly hard to see but I’ve added a m12 shoulder bolt as the shaft for the weapon as I’ve seen it being used by other VSs and cause I’m trying to save weight where I can.

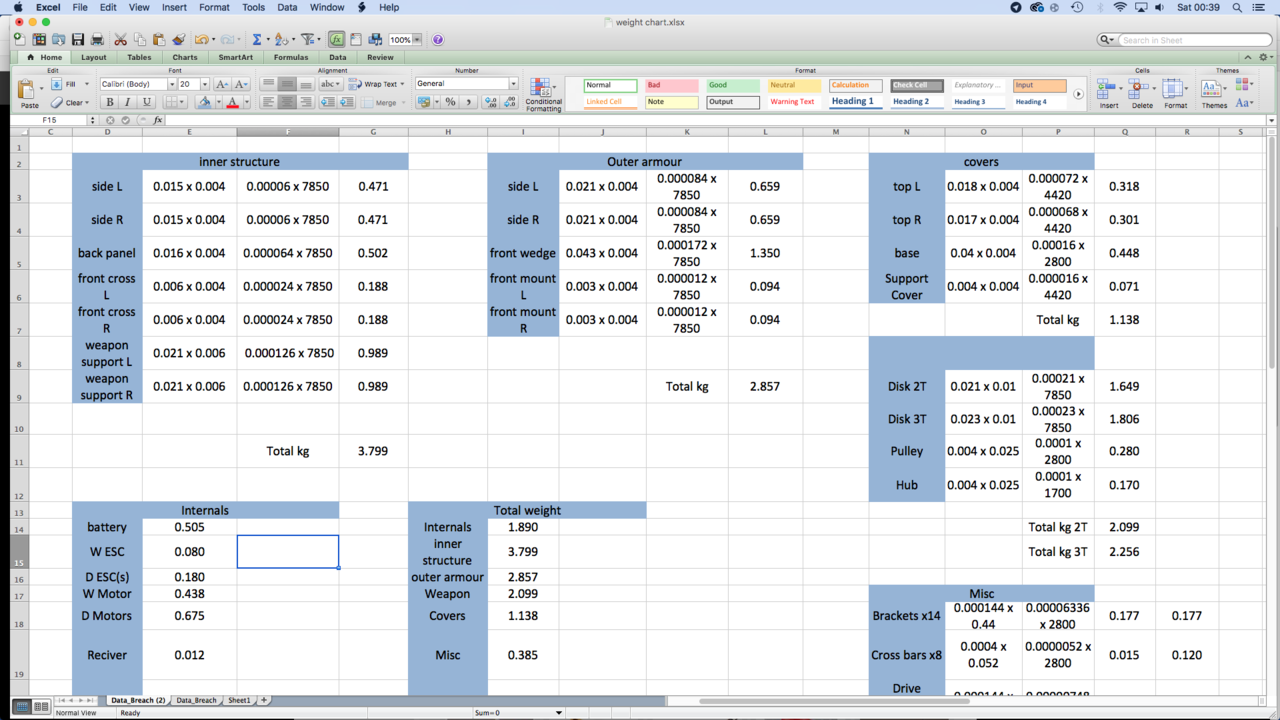

And speaking of weight saving here is the rough weight calculations. So far the approximate weight is roughly 12.2kg.

Also while I remember what would be the recommended ground clearance for arenas like the RoboChallange arena at the moment it's got a 5mm ground clearance, will that be enough or should I am for about 7.5mm-10mm?

Leave a comment:

-

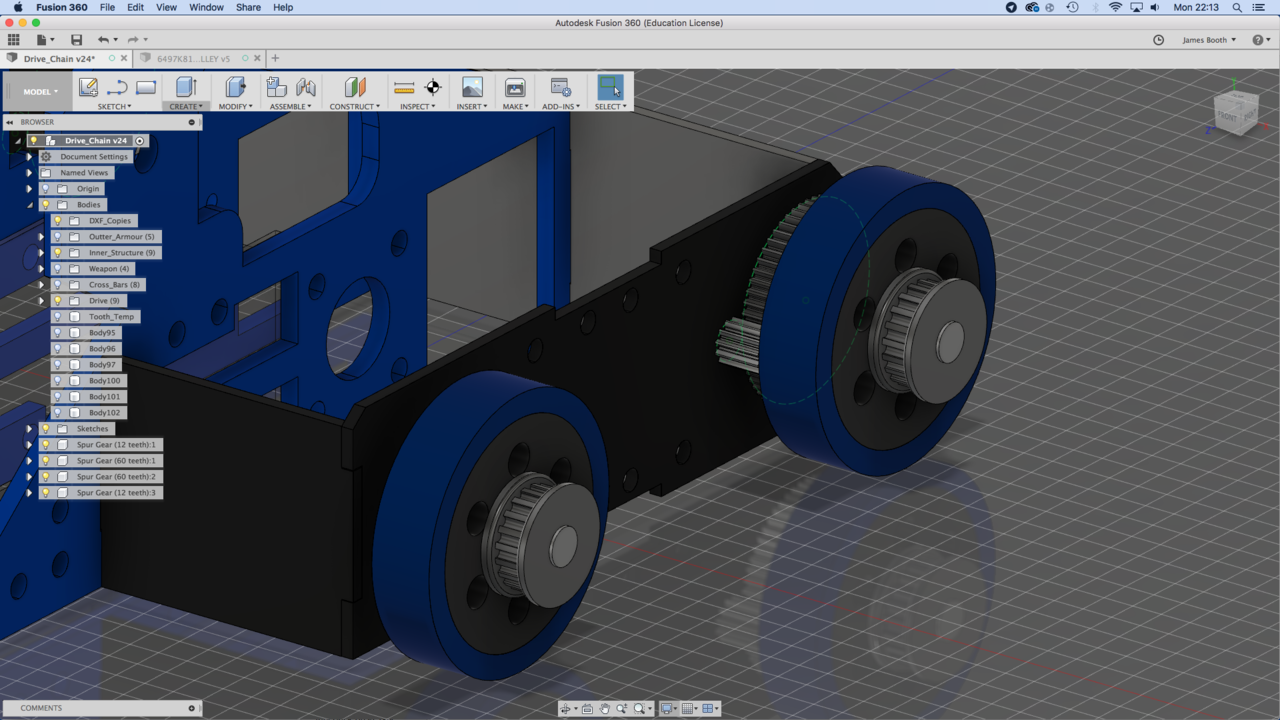

And here we go, I was able to make pulley models following the specs of pulleys online, using one of those McMaster Carr models to get the tooth profile. Now I need to look at wether to have the wheel and pulley as separate items or make them one solid object.

Leave a comment:

-

I'll have a look cheersOriginally posted by Maxamuslead View Postthats a good idea, also you can import a model from McMaster Carr which does a limited number of types but is useful

Leave a comment:

-

thats a good idea, also you can import a model from McMaster Carr which does a limited number of types but is useful

Leave a comment:

-

oh ok, I'll give that look cheersOriginally posted by TechAUmNu View PostIf you are a student you can download Inventor and use the design tools in there to generate pulleys, belts, gears, chains, etc with the correct center distance and then import them to fusion 360.

https://www.autodesk.com/education/f...r-professional

Leave a comment:

-

If you are a student you can download Inventor and use the design tools in there to generate pulleys, belts, gears, chains, etc with the correct center distance and then import them to fusion 360.

https://www.autodesk.com/education/f...r-professional

Leave a comment:

-

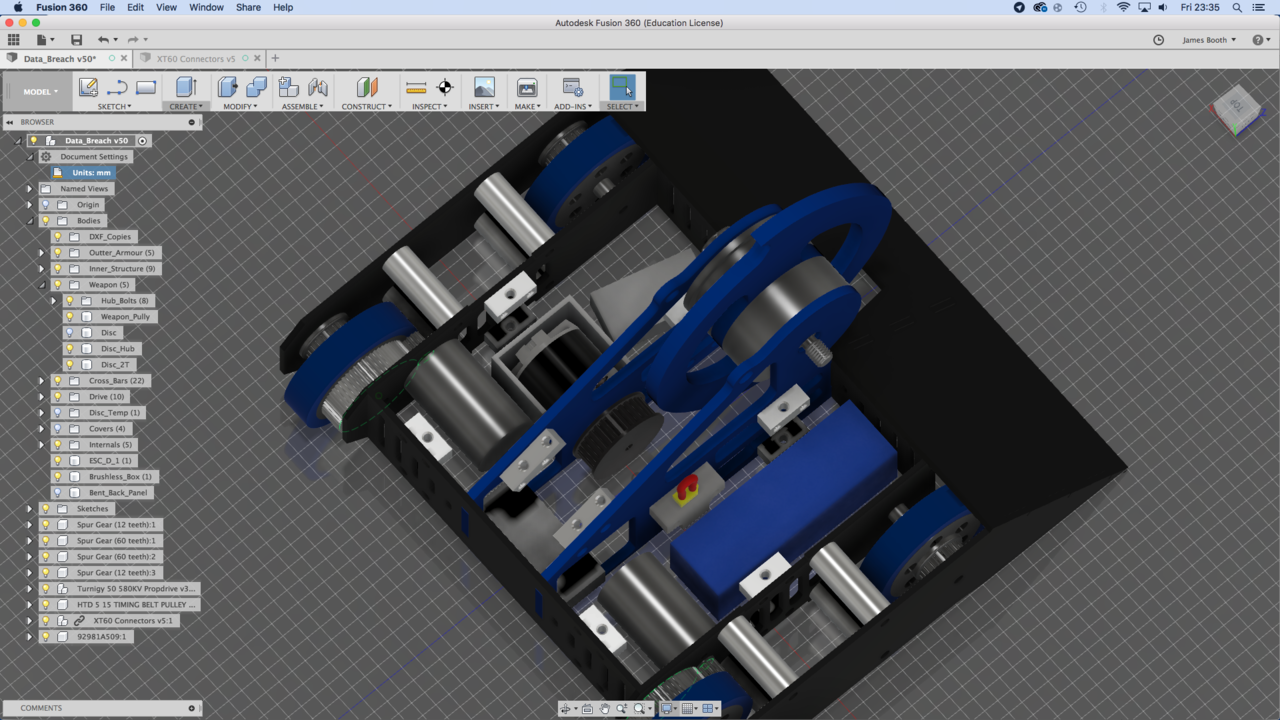

Finally was able to give Fusion 360 a go, not a fan of the interface but I’ve managed to persevere. Here is the current progress on the spinner concept and I feel happy to also reveal its name Data Breach. Still some refining to the hardox panels needed.

And I’m having slight issue with finding timing pulley models for the drive and weapon. Does any body have some I could use? or know where I could find some?

Leave a comment:

-

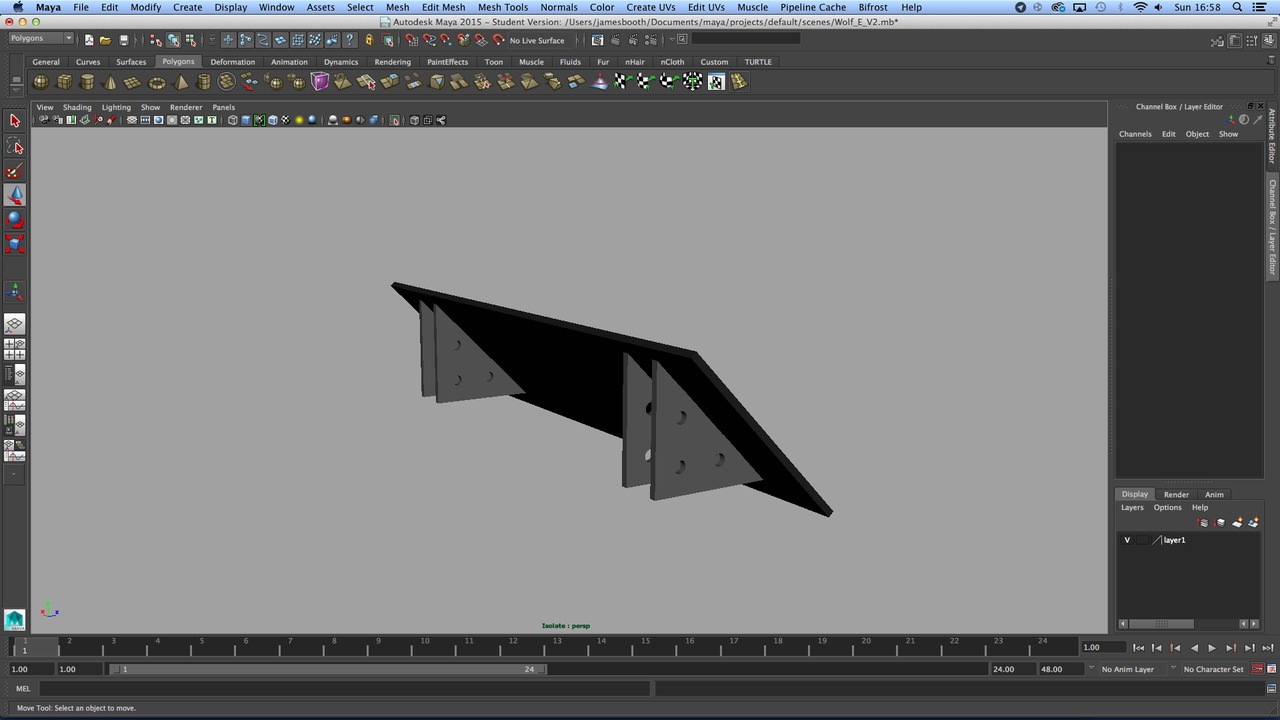

Here is a look at CSB’s front wedge and the new planned means of mounting it to the HDPE bulkheads.

Leave a comment:

-

Did a bit more to my newest concept. Working on the panels that slot and tab together.

Leave a comment:

-

History repeats itself, during a limbo of not being able to do any work on my bots I let my creative ideas loose and like with my 6wd CSB 2 concept, I ended up creating a new bot, the idea for which started out in a video game.

Leave a comment:

-

Leave a comment: