Announcement

Collapse

No announcement yet.

Team Coolspeedbot: first feather weight robot

Collapse

X

-

Hmm. Maybe try one of those spring-loaded punches? Not sure if they'd be good enough for hardox.

-

I did but it is a bit iffy when I hit it.Originally posted by R9000 View PostWhen you drilled the holes, did you use a centrepunch? That should make an indent to stop your drillbit walking off.

Leave a comment:

-

When you drilled the holes, did you use a centrepunch? That should make an indent to stop your drillbit walking off.

Leave a comment:

-

Some Aluminium parts arrived from Dave Moulds and Engineering Network. The pretend-o build now includes the side panels. Sadly all of the threaded bars for bolting the frame together had issues with holes not being accurate enough for the job as in each one had at least one hole out of place, the drill wondered when drill pressed it. I’ll get more aluminum and try to drill and tap them better this time.

Leave a comment:

-

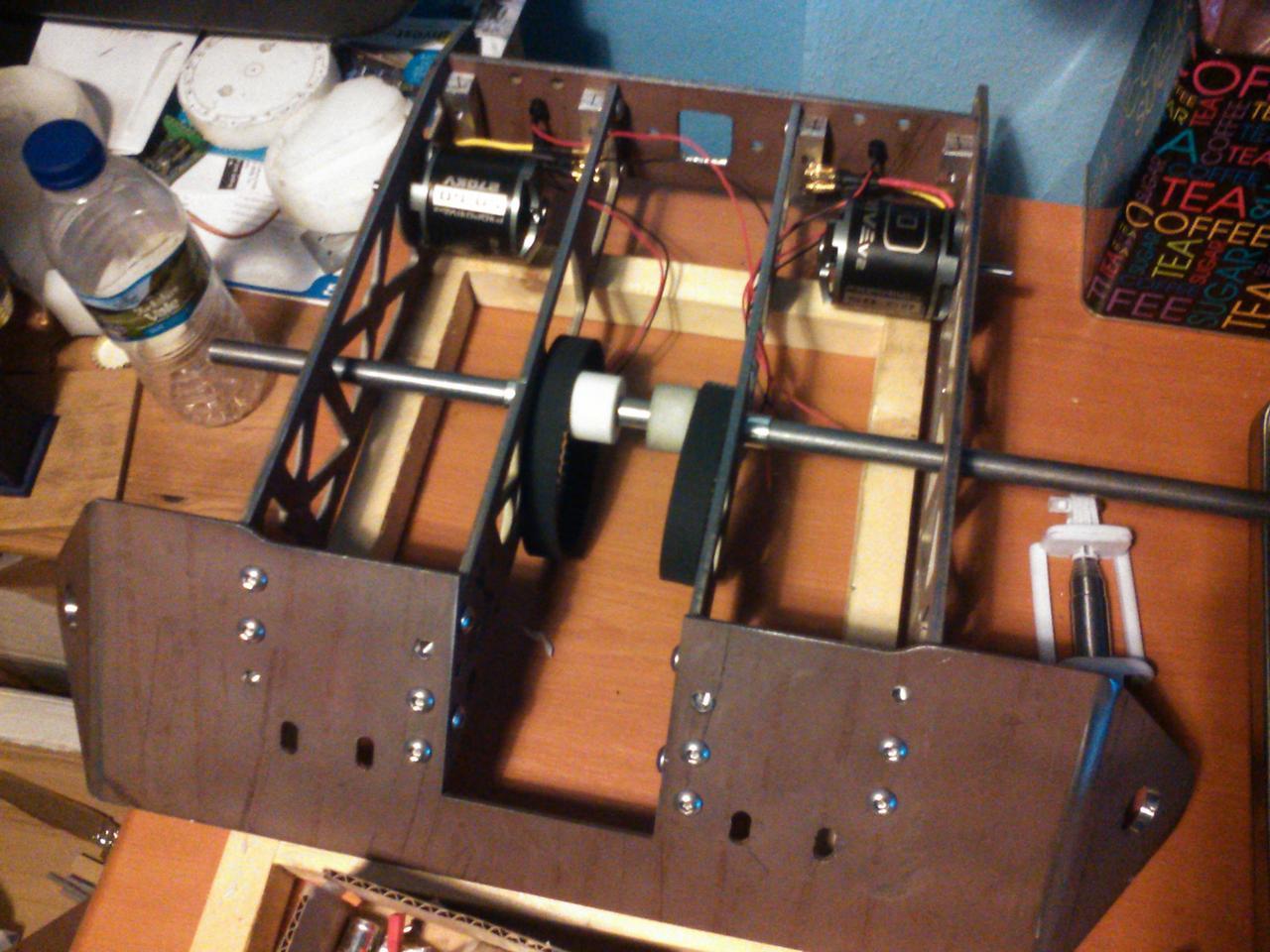

After a few days work, I’ve got a pretend-O build, I’ve finally moved CSB 2.0 from the floor to its cradle. I also test fitted the motors and part of the weapon mechanism (using the locking bar as a stand in for the shaft). Some of the threaded bars are a bit off in places so might replace them otherwise I'm going to have to do a lot of hole filling and resizing. Granted I'm dreading having to countersink some of the holes.

Leave a comment:

-

They can only do straight cuts. Which also means all parts have curf on them. If you get a 3d waterjet, or one that compensates for curf you can get perfectly straight cuts or any angle you want.Originally posted by Eidg View PostLooks fine congratulations, love it.

Can k-cut make angled cuts for the wedge, or do you grindig it in shape?

Leave a comment:

-

Kcut are a water jetting firm who also have access to a press. They would of cut out the metal as designed a d bent it if required.

Leave a comment:

-

Looks fine congratulations, love it.

Can k-cut make angled cuts for the wedge, or do you grindig it in shape?

Leave a comment:

-

Yeah this build is speeding along. I'm trying to improve on my past build time of 18-24 months.Originally posted by Shooty View PostShame to hear about the drill bits but those are some nice hardox pieces! Didn't realise the build was this far in progress, looking promising.

Leave a comment:

-

Shame to hear about the drill bits but those are some nice hardox pieces! Didn't realise the build was this far in progress, looking promising.

Leave a comment:

-

The Hardox arrived from K-cut. Working on the Aluminium threaded bars, well I was till the tap broke and the drill bits went blunt. New Taps and drill bits ordered.

New Taps and drill bits ordered.

Leave a comment:

-

Just takes some time and practise and you'll get there.Originally posted by firefly1 View PostWish I could CAD this well XD It looks great!

Leave a comment:

-

Thanks, we'll have to wait and see, once it's built.Originally posted by TeamKnightshade View PostThis looks really impressive, lovely CAD work. This could be tough to beat!

Leave a comment:

Leave a comment: