Announcement

Collapse

No announcement yet.

Team Coolspeedbot: first feather weight robot

Collapse

X

-

2mm hardox won't hold up against spinners for long at all on a featherweight, 4mm gets bent fairly often, but 5mm would probably get bent the same way so id say a 4mm hardox wedge with a spare or two is the best way to go.

-

Well 5mm would be the max thickness Wolf-E can use on the wedge so I'm happy to use anything between 2-4mm if it's Hardox thats cool.Originally posted by R9000 View PostAs far as I've seen, if you're talking Hardox, 5mm is ambitious. My bot has a 4mm scoop and that is completely rigid and feels thicker than you'd think. I think most people have 2-4mm steel or Hardox armour, otherwise it gets very heavy and quite expensive. HDPE you want about 20mm for the sides, 10-ish on top, but since you're doing a wedge you might want a bit thicker, I'm not sure.

Leave a comment:

-

As far as I've seen, if you're talking Hardox, 5mm is ambitious. My bot has a 4mm scoop and that is completely rigid and feels thicker than you'd think. I think most people have 2-4mm steel or Hardox armour, otherwise it gets very heavy and quite expensive. HDPE you want about 20mm for the sides, 10-ish on top, but since you're doing a wedge you might want a bit thicker, I'm not sure.

Leave a comment:

-

So moving from removable links to armour, could I get recommendations for armour, I'm looking at around 5mm thick, but I say that with limited understanding.

Leave a comment:

-

Great thing about the 100W irons they dump so much thermal power into the joint the rest of the connector barely gets any time to heat up before the joint is made and you can remove the soldering iron. I've done plenty of solder cup EC5s with minimal thermal distortion.

Leave a comment:

-

Yeah, I agree with you there Alex, I melted the first link trying to fix it.Originally posted by Eventorizon View PostAlso, so you can pump in more heat, you can push a male and female connector together to double your thermal mass. That way when you use the 100W Iron, you are very unlikely to melt the connector itself while you solder; as it will take roughly twice as long to heat up. Its not necessary but I find gives more to hold and gives you a bit more tolerance before you have to stop, let it cool and try again.

Leave a comment:

-

Also, so you can pump in more heat, you can push a male and female connector together to double your thermal mass. That way when you use the 100W Iron, you are very unlikely to melt the connector itself while you solder; as it will take roughly twice as long to heat up. Its not necessary but I find gives more to hold and gives you a bit more tolerance before you have to stop, let it cool and try again.

Leave a comment:

-

Oh my iron uses 40w.Originally posted by shakesc View PostYep - I use XT60's with a wire loop. I bought a 100W iron from Maplins (they are cheap). You can get alot of heat into a small area stopping the housing from getting damaged. With XT60 I always tin both the connector and wire.

Leave a comment:

-

Yep - I use XT60's with a wire loop. I bought a 100W iron from Maplins (they are cheap). You can get alot of heat into a small area stopping the housing from getting damaged. With XT60 I always tin both the connector and wire.

Leave a comment:

-

If you pull off the wire from the connector, the soldering is "not good".

If you can pull the wire appart, it's too thin.

A good solder joint is as strong as the connector or the wire.

Leave a comment:

-

I think you're supposed to be able to pull on the wire. If it's coming undone, either find a better connector (like the red ones which require you to push the contact into the connector end) or check your solder connections. I suppose you could also try reinforcing it with some tape, but I'd only do that as a last resort.

Leave a comment:

-

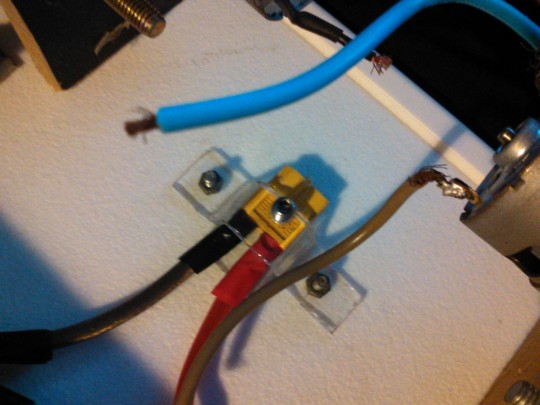

had a go at mounting the connector for the link. Kinda works could do with suggestions though.

On another note the wire on the link keeps on coming undone on the same side of the connector, how do people grip the link when they remove it? Pull on the wire? or grip the connector?

Leave a comment:

-

Could someone show me how they make it easy to insert their removable link into the robot or how they mount the connecter (that the link connects to) to the robot. Because the wire on my link keeps coming undone after a few trys to insert and remove it. it's a xt60 connector.

Leave a comment:

Leave a comment: