Announcement

Collapse

No announcement yet.

Team Coolspeedbot: first feather weight robot

Collapse

X

-

I would get that bent. Its not very expensive, we just had 4 new armour sections done by kcut.

Leave a comment:

-

I'll do that when I get a chanceOriginally posted by maddox10 View PostJohn is very forthcoming in that kind of information, just ask.

Leave a comment:

-

I would just do that but I'm not sure whats the max they can bend.Originally posted by R9000 View PostPaint job looks great. If you're getting it water cut via someone like kcut, you might as well ask them to bend it for you as well. It's cash money but it won't just snap like a weld can sometimes.

Leave a comment:

-

Paint job looks great. If you're getting it water cut via someone like kcut, you might as well ask them to bend it for you as well. It's cash money but it won't just snap like a weld can sometimes.

Leave a comment:

-

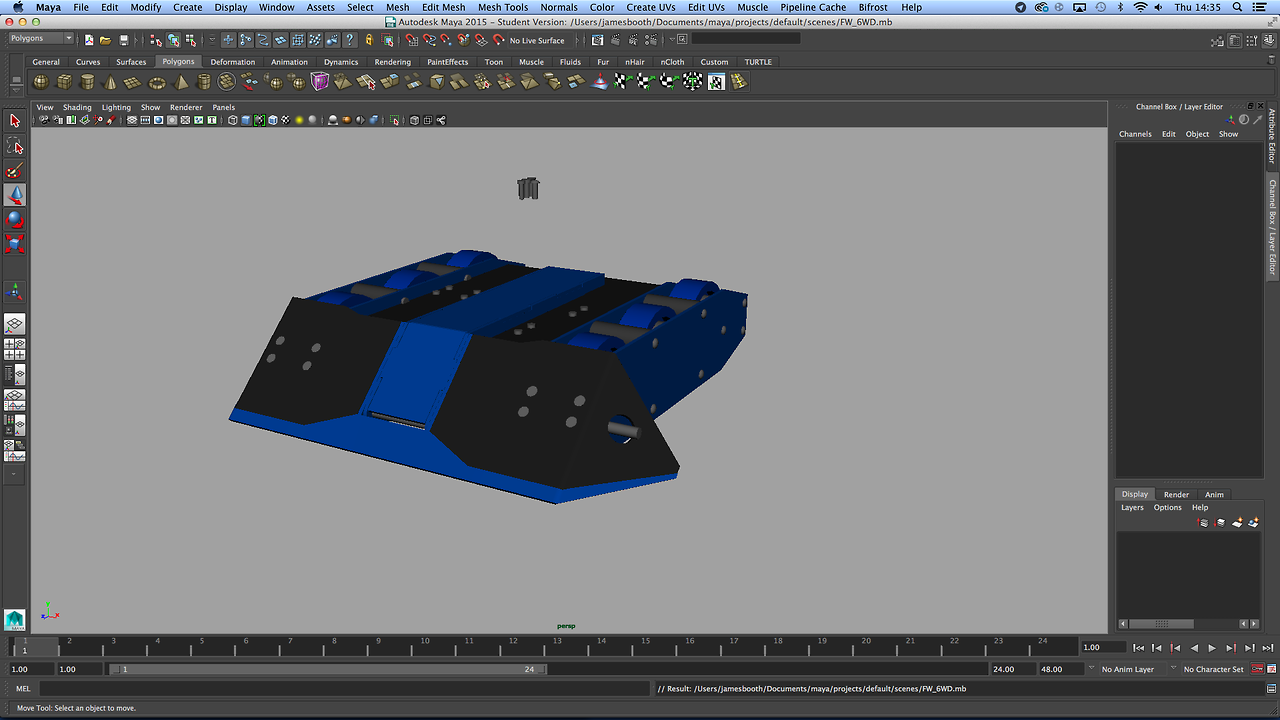

I'm still unsure which is a more practical solution to the wedge, should I get it bent or should I get it welded? But in the mean time check out this potential paint job idea.

Leave a comment:

-

I seeOriginally posted by maddox10 View PostIf you don't have a 50 tons press with the right add-ons, it's not something you can do at home.

I have a hand-bender, and the biggest I can do is 100mm wide 3.2mm thin Hardox 450. And that because I modified that poor tool to accept that abuse.

Anyone wishing for a sharp crease, a weld will have to do.

For them who want a smooth bend, it's money time.

Leave a comment:

-

If you don't have a 50 tons press with the right add-ons, it's not something you can do at home.

I have a hand-bender, and the biggest I can do is 100mm wide 3.2mm thin Hardox 450. And that because I modified that poor tool to accept that abuse.

Anyone wishing for a sharp crease, a weld will have to do.

For them who want a smooth bend, it's money time.

Leave a comment:

-

I see, I've had a look but I'm not sure I fully understand how to implement it into the design.Originally posted by maddox10 View PostIt can be bend 180°, but with the right radius. Hardox will break if bend too sharp.

You can find the working instructions here.

https://www.ssab.com/download-center...ormi&dcSearch=

Leave a comment:

-

It can be bend 180°, but with the right radius. Hardox will break if bend too sharp.

You can find the working instructions here.

https://www.ssab.com/download-center...ormi&dcSearch=

Leave a comment:

-

Well I'm unsure whats the max angle the wedge could be bent before the material (like 4mm hardox) breaks.Originally posted by Ocracoke View PostI would have thought it would be stronger as a single piece formed into the three angles rather than a three piece wedge.

Leave a comment:

-

I would have thought it would be stronger as a single piece formed into the three angles rather than a three piece wedge.And what would be the best way to achieve the 45 degree angled sides to the wedge? I don't know if it can be done by bending a single part or simply have it in 3 parts and welded them together.

Leave a comment:

-

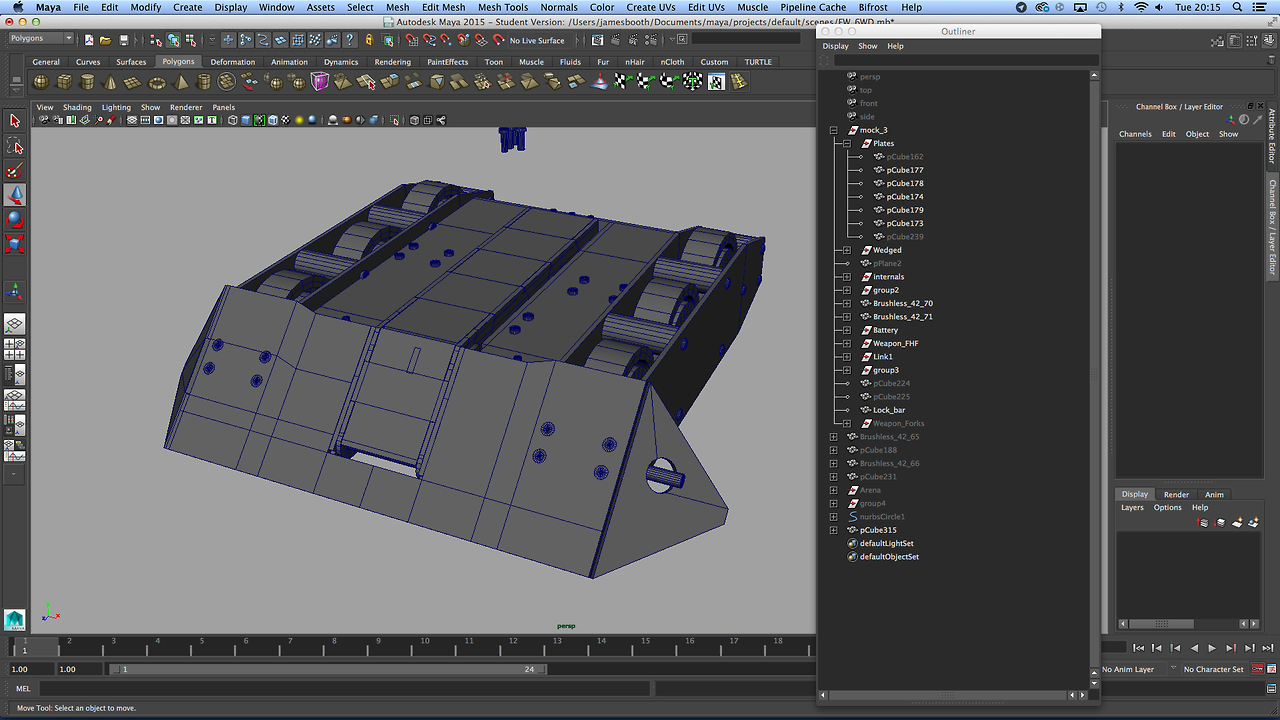

Been working on the wedge of CSB's design and reached a head-scratcher. What material should I use on for the wedge so that it can be countersunk so the bolts are flush?

And what would be the best way to achieve the 45 degree angled sides to the wedge? I don't know if it can be done by bending a single part or simply have it in 3 parts and welded them together.

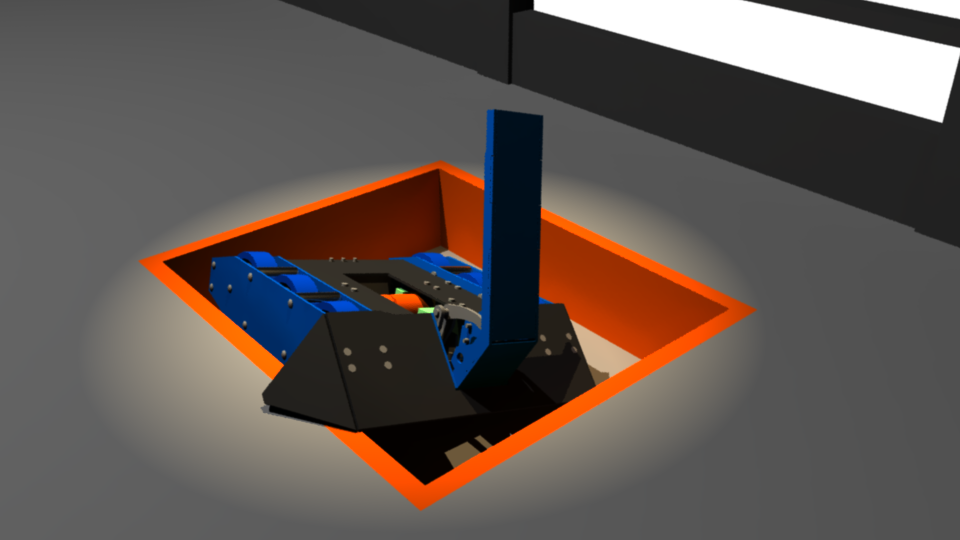

Oh and almost forgot this little render I did for a laugh

Leave a comment:

-

Well I am considering it but if I choose to work on CSB instead of Wolf-E I'll end up wasting the Drill motors and brushed ESCs as CSB is designed to be brushless. Plus I could do with getting some experience with the weight class first and Wolf-E is a basic machine to get my head round things.Originally posted by Theo View PostI think you should do this instead of Wolf-E. All you need is a beefy motor and gearbox with an accompanying ESC and you have yourself a, by the looks of it, much better looking machine. Or you could still do Wolf-E if you have reliability in mind.

Leave a comment:

Leave a comment: