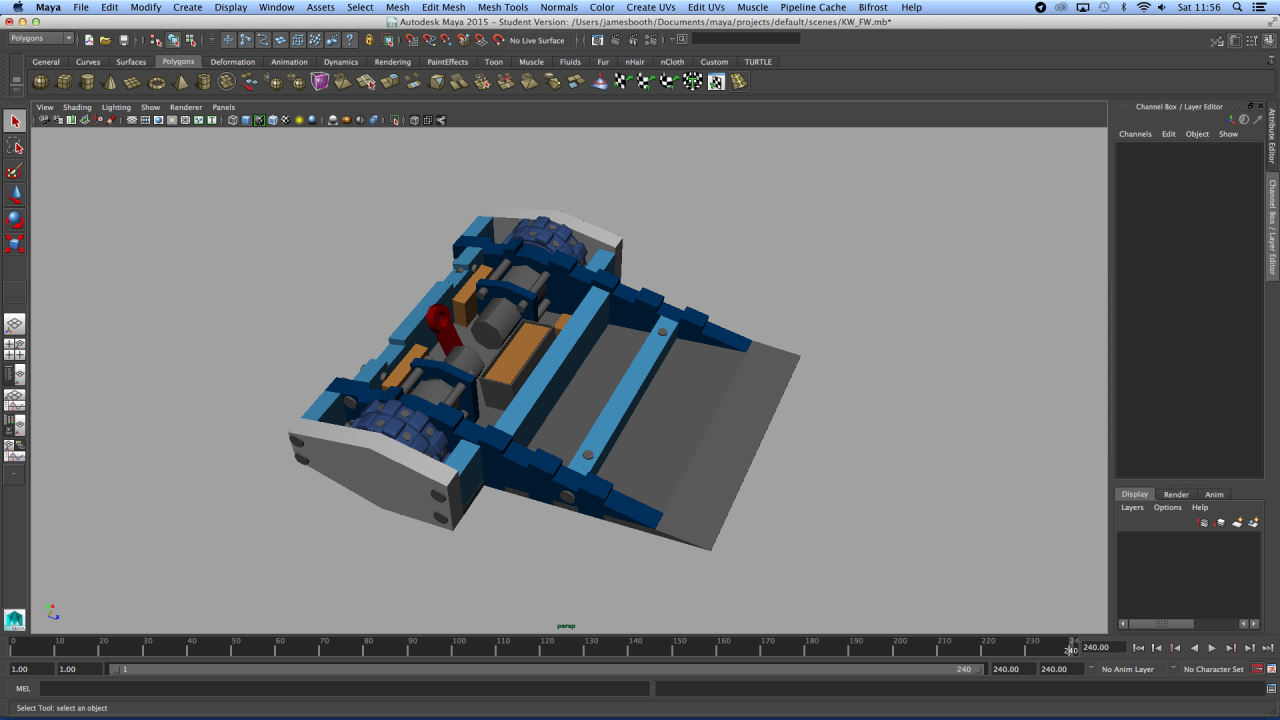

I see what you mean David, if you can do a sketch that might help a lot more although bare in mind that Wolf-E was designed to me made with HPDE with the top and bottom plates/ wedges made out of hopefully a metal material (depending on weight and cost).

Announcement

Collapse

No announcement yet.

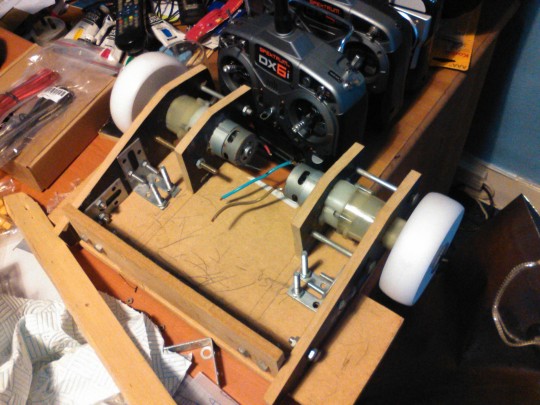

Team Coolspeedbot: first feather weight robot

Collapse

X

-

Yeah my robots are made from biscuit tins and chopping boards so I'm not really an expert. But after building naff robots since 2012 you do start to pick bits up here and there. I spose what I mean is you don't need angled wedges, just a robot that's sort of all one shape so it's hard to get a bite on lol.

Comment

-

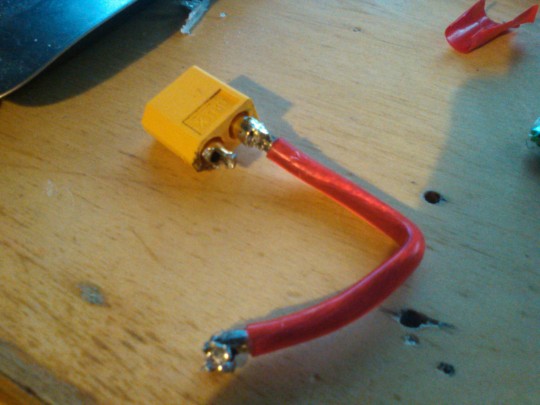

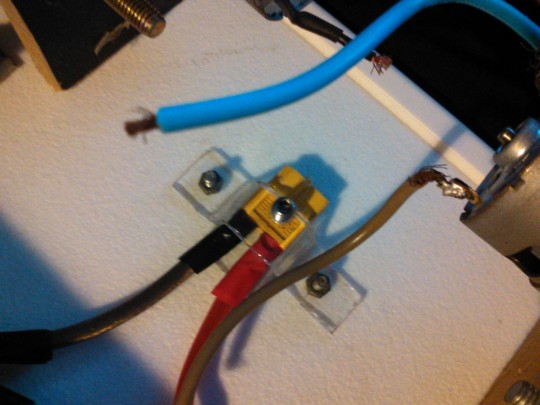

I think you're supposed to be able to pull on the wire. If it's coming undone, either find a better connector (like the red ones which require you to push the contact into the connector end) or check your solder connections. I suppose you could also try reinforcing it with some tape, but I'd only do that as a last resort.

Comment

Comment