Rofl^ / cheers guys, yeah it's a bitsy thing, about to get even bitsier with electronics mounting. Want to actually mount the internals in Rango, because some guy designed it with a load of belts going everywhere. Going to mean a lot of small standoffs and tiny plates!

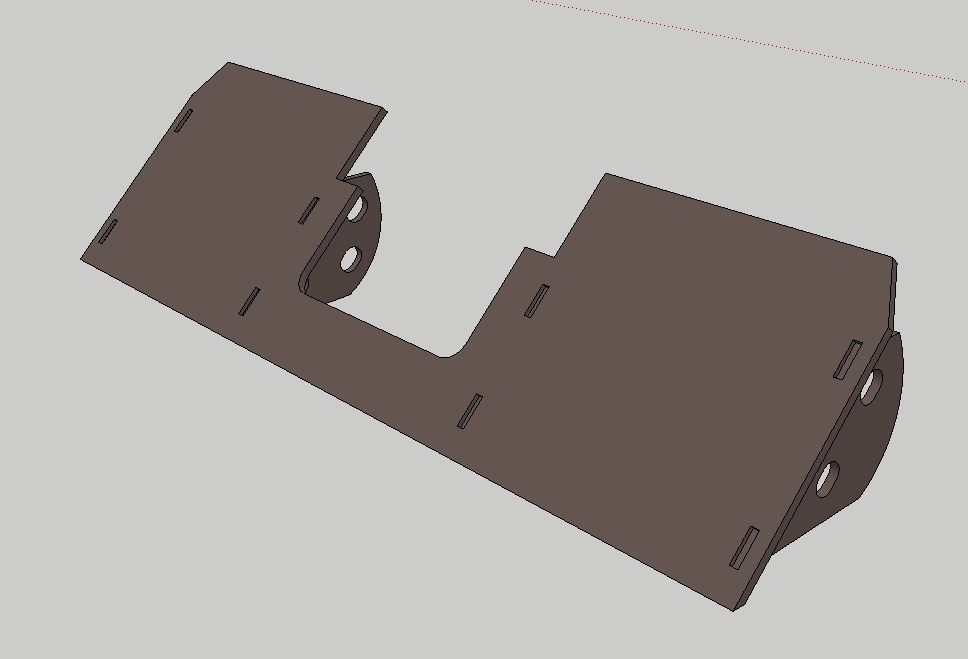

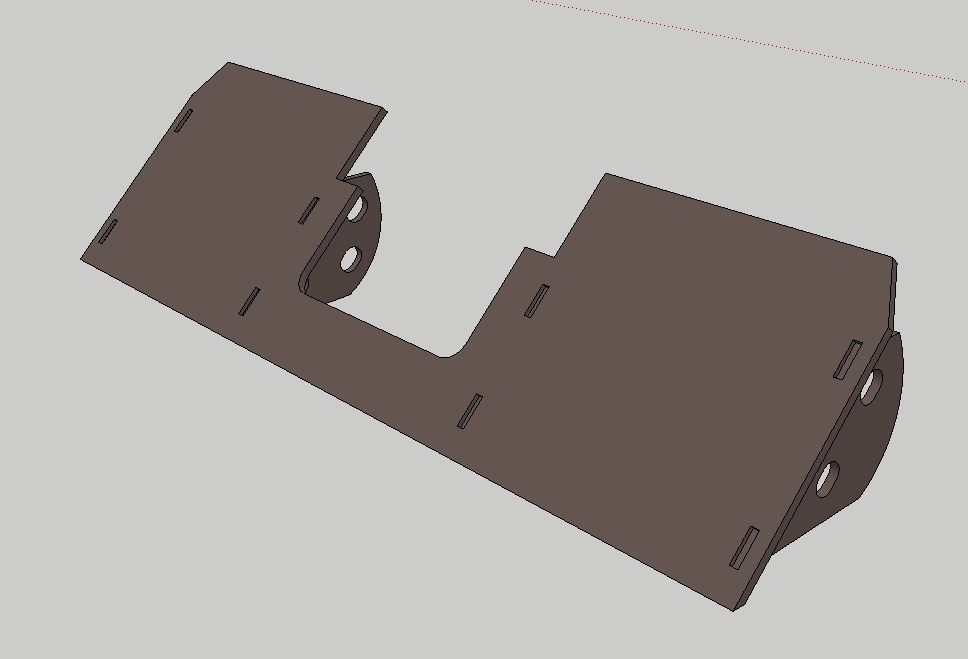

Also, the wedge has been watercut, and Mario has already welded it up. He's doing some work for T2 as well, so it'll be couriered to here sometime next week, hopefully alongside. It's 3.2mm hardox and weighs 1kg.

It's slot-and-tab to make positioning for welding straightforward, and the mounting brackets are slotted so I can set the height depending on who I'm fighting, or leave it loose and have it *hopefully* completely ground-scraping.

The pulleys are now bolted to the wheels which allows me to see where exactly the belts will all pass, so I can now start to position internals around them and devise mounts. Not done much buildy stuff today, the chassis is on the floor and I'm throwing speed controllers at it to see how they fit.

Also, the wedge has been watercut, and Mario has already welded it up. He's doing some work for T2 as well, so it'll be couriered to here sometime next week, hopefully alongside. It's 3.2mm hardox and weighs 1kg.

It's slot-and-tab to make positioning for welding straightforward, and the mounting brackets are slotted so I can set the height depending on who I'm fighting, or leave it loose and have it *hopefully* completely ground-scraping.

The pulleys are now bolted to the wheels which allows me to see where exactly the belts will all pass, so I can now start to position internals around them and devise mounts. Not done much buildy stuff today, the chassis is on the floor and I'm throwing speed controllers at it to see how they fit.

Comment