Is there a reason for not using aluminium timing pulleys? Steel seems overly strong and must add a heap of weight.

Announcement

Collapse

No announcement yet.

Rango - Build diary

Collapse

X

-

No, and it does. It's me not realising HTD5 pulleys are steel from the supplier I got HTD3 ones in aluminium. I thought these would be aluminium too (it does say they're steel, but apparently I don't have eyes). I got a surprise when I felt the box they were shipped in, let me tells ya. Simple case of assuming, and assuming wrong.

This is an area I should be able to save serious weight for future upgrades. Too late now, unfortunately. Even aluminium seems stronger than necessary, I'd quite happily use a plastic variation if they could be sourced.

Comment

-

I once got some plastic timing pulleys to go on a wheel design like yours. I can't recall what type of belt they took, but they were a similar size and came from SDP/SI in the USA: https://sdp-si.com/eStore/Catalog. They may even have a local reseller or you can sometimes work out the original manufacturer from the spec.sheets and Google a closer source. Hope that helps in the future...

Comment

-

Cheers, I will do some searches post-champs. I feel ridiculous for making the assumption, and I should have checked, but I now know I won't do it again in a hurry, so not all is lost.

QTC sell nylon HTD5 pulleys, but they're in New York, and probably cost masses anyway. Website is messing around so can't find out. Pretty sure I could source aluminium ones in the UK, or alternatively another competitor (Alex) is 3D printing HTD5 pulleys. His setup is different to mine but if his work that may be by far the easiest/cheapest option. It could save me the guts of half a kilo, going with plastic!

Heavier drum for 2015 methinks.

Comment

-

That's the plan! Though the drum shouldn't have too much kick, the design isn't optimised for packing an inertia-loaded hit, and the spinning mass is actually a little under 2kg. I'm hoping the single tooth means, though overall energy stored is quite small (relative to other spinners), it should dump said energy into the enemy more often, or more effectively. All I'd like it to be able to do is roll robots over, anything more is a bonus.

Small update, Jeroen has now sent the box of goodies. Hoping it'll be here sometime mid next week.

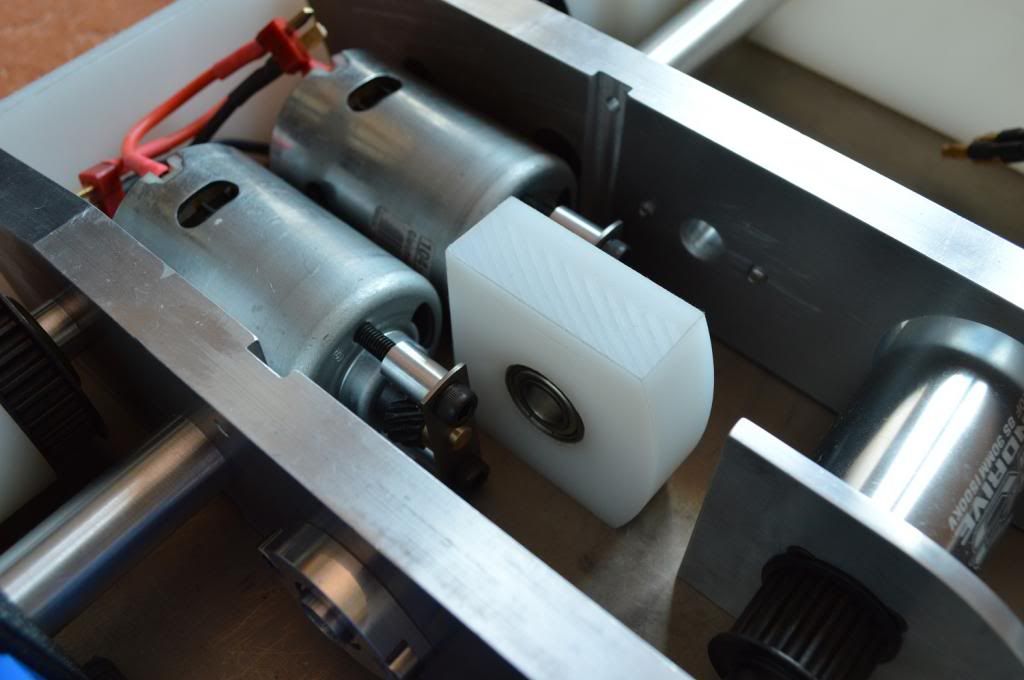

I have been making some of the fiddly bits. I was going to not bother with motor shaft supports but figured for what they'll add in weight, it's worth it:

The combined effects of the kind of gear teeth and the braking function fighting the robot's momentum when coming to a stop means the pinion will get pushed and pulled in all directions. This little plate, once tightened down, should at least limit by how much the 5mm motor shafts can flex. The stubby bronze bushing captures the end of the motor shaft:

Also made the bearing block for supporting the other side of the right angle shafts. Some semi-pretendo 4 u.

Going to go and bolt the pulleys to the wheels, which allows me to see where the belts will finally run (and if the wheel bushing alignment is going to be off), so I can make other bits and plan the electronics positions from there.

Comment

Comment