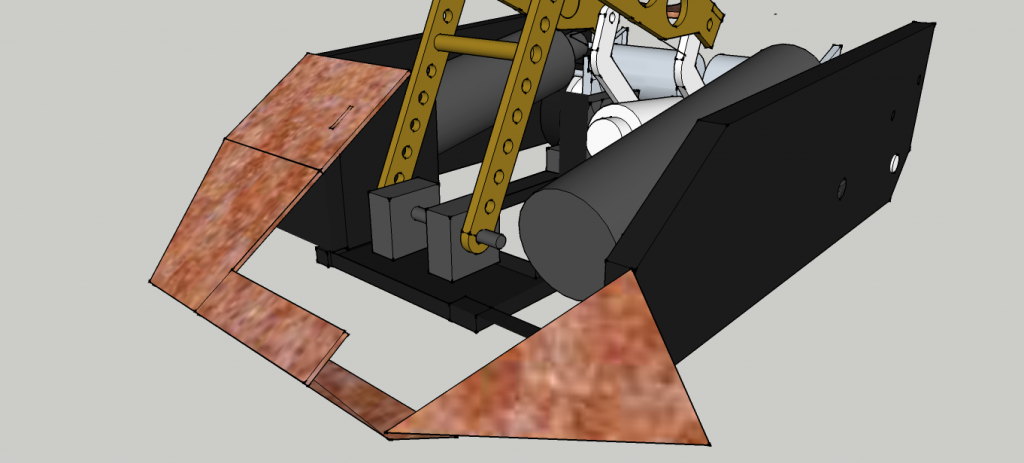

Is the axle fixed or rotating? I would move the top screws down as close to the wheel as possible to minimise the effect of flexing in the plastic on the gear mesh. Is the motor mount attached to the base plate or just the sides?

Announcement

Collapse

No announcement yet.

Team Pasty Build Diary: Loki

Collapse

X

-

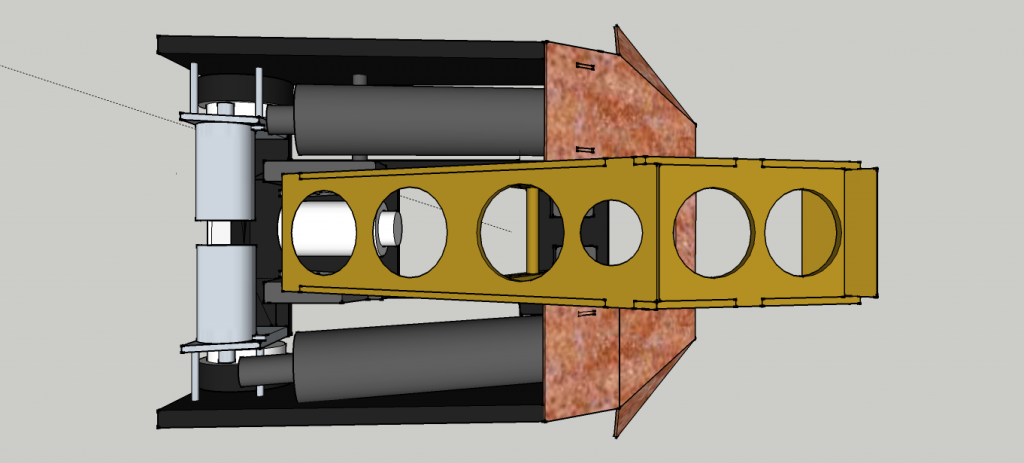

As your in the design stage, I would urge you to move the motors so they're side by side. For you this is easily achievable because of your gearing set up. Reducing the width will reduce your overall size, meaning more wieght for armour. Out if interest what are the overall measurements?

Comment

-

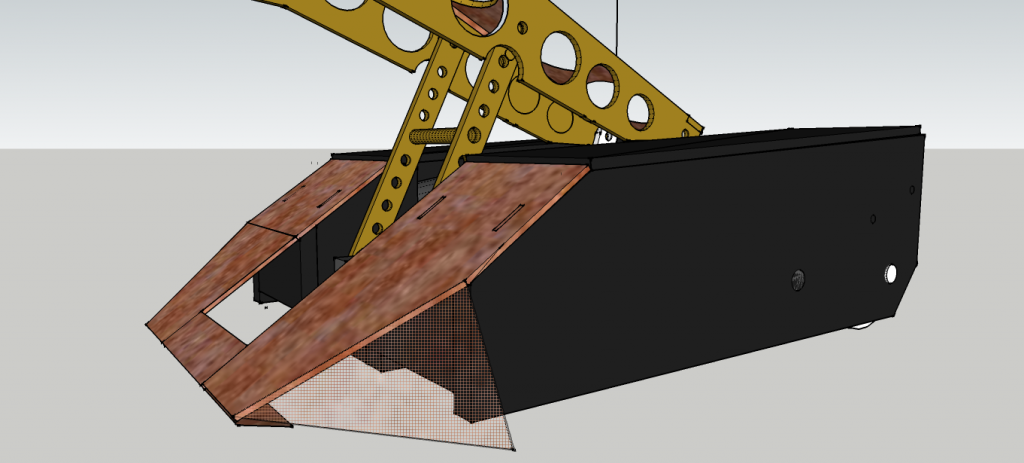

Gabe I have considered side by side motors the only problem is the bottles lie lengthways on either side of the arm so I it needs to be that width to accommodate them anyway and the whole thing would either have to be longer so the motors go behind the ram or alternatively in the spaces where the bottles are now so then would probably have to be taller. Also I've got the motors with gears welded on already lol.

Max I've got some Oilon to make bushings, do they just reduce friction and wear?

Comment

-

Aluminium is terrible as a bearing surface as it is one of the worst metals for galling http://en.wikipedia.org/wiki/Galling. Using a plastic Oilon bearing will help a lot but I would definitely recommend using one of the harder grades of aluminium, polishing the surface AND lubricating it.

Comment

-

Again restricted by length of the bottle + motors unless I shorten it and put the bottles above the motors but will have to be taller again. The main body is 410 with an 'empty' wedge giving the extra 90.

Thanks for the advice Nick, I'm all new to custom transmission. I've been a drill motor guy so far so any advice is very welcomed. Is 6082T6 suitable?

Comment

-

hey! I've not looked through your hole build thread so im not too sure, but are you have just a single pair of wheels at the far back?

if you are i'd consider moving them at least to the middle or at least more forward cause you'll find it with handle horribly!

4 wheel drive would be cool, unless that's what your doing anyway in which case egnor me!

Comment

-

I used 14mm 7075 super-polished wheel shafts and oilon for bushings. The belt tension puts huge sideload on the bushings and in my case, the oilon was a total flop. It's too soft. I ended up having to bore the bushings way oversize to loosen the belts to get to an acceptable amount of friction. I intend to run regular nylon next year. Bearings would be ideal but can fail, whereas a nylon bushing with low enough friction is indestructable, so not a bad compromise.Last edited by Ellis; 3 November 2014, 00:10.

Comment

Comment