Re: Liftoff (FW) build diary

Maybe I missed something, but why not just design it so that the flipping arm is also the self righter?

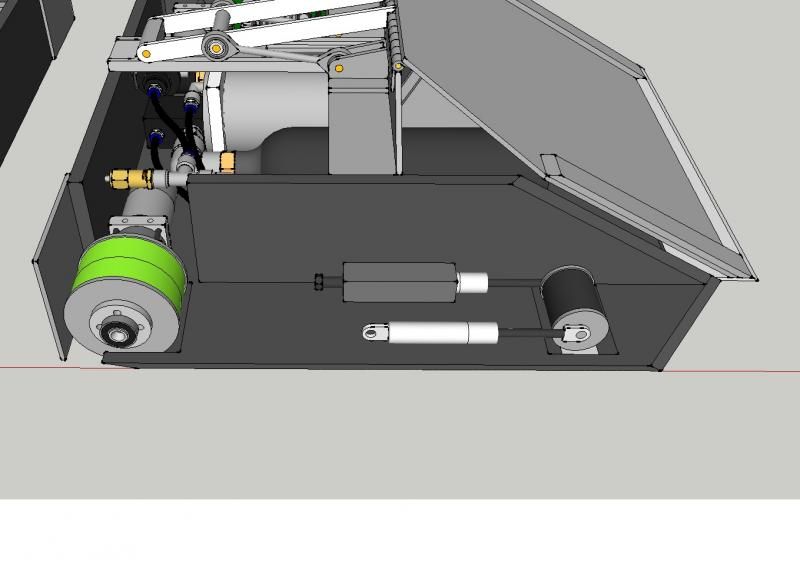

I thought about using friction drive for a second set of wheels but quickly decided against it since I figured as t he tyres ware they will no longer touch each other and any debris will jam between them.

Maybe I missed something, but why not just design it so that the flipping arm is also the self righter?

I thought about using friction drive for a second set of wheels but quickly decided against it since I figured as t he tyres ware they will no longer touch each other and any debris will jam between them.

I'll try!

I'll try!

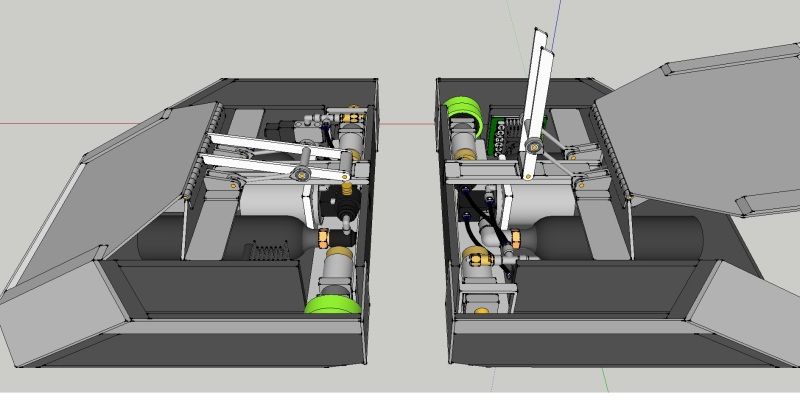

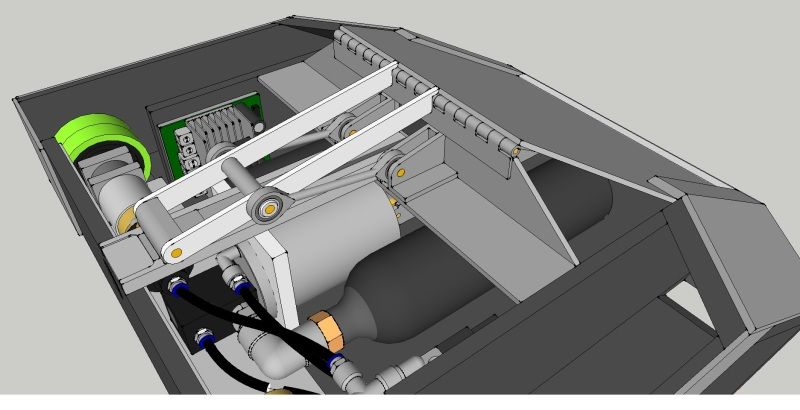

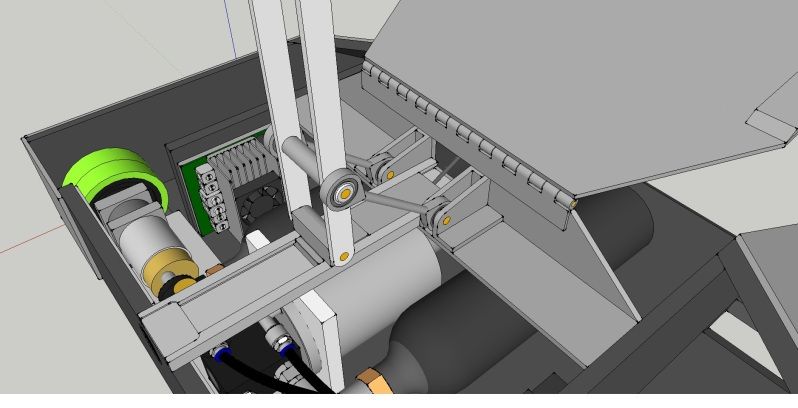

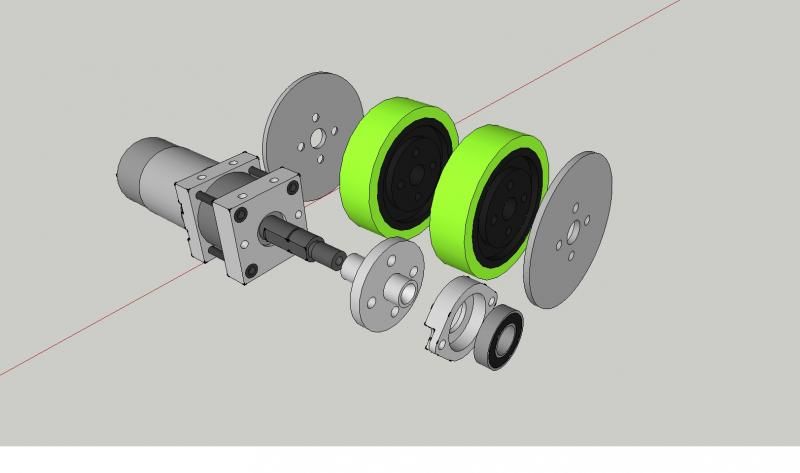

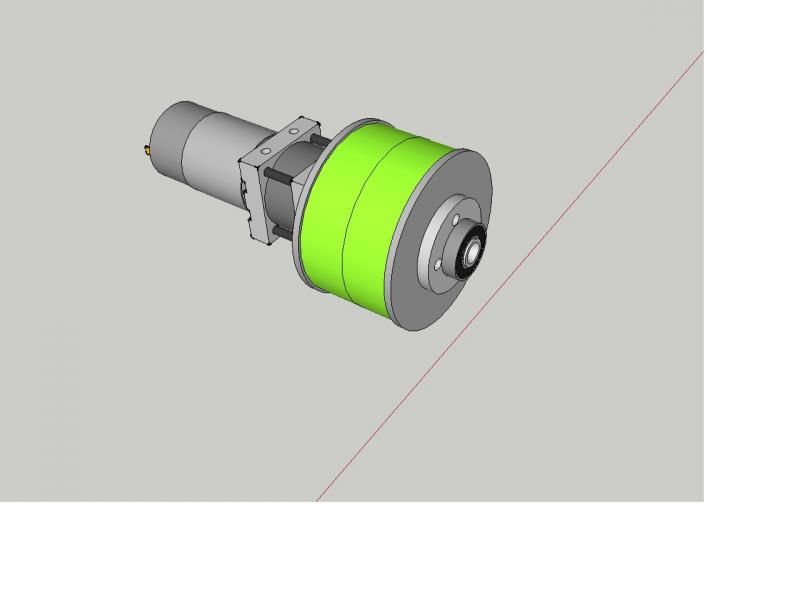

And again, great CAD! An exploded drawing in Sketch-up!

And again, great CAD! An exploded drawing in Sketch-up!

Comment