Re: Liftoff (FW) build diary

Actualy, the wire idea is being used in industrial piping welding processes. But that requires some expensive machines. It's ment to weld tubes and connections together.

The tool I used was a combination machine. A mirror welder but with attachments for wire-welding.

For mirror welding (the mirror is a polished stainless steel plate). Put the tubes in the hydraulic clamps. Scan the barcode of the parts. The parts get pressed at a certain pressure against the mirror. The mirror gets heated to a certain temperature. When the parts have the temperature desired, the mirror is withdrawn, and the clamps press the parts together. Never seen neater butt-joints.

Wire welding requires elbows and straight connection pieces with the wire in them. But the idea is about the same. Push the cleaned parts together, align. Push the wire-connectors from the machine on the studs on the parts, scan the bar code, and press start. When the buzzer sounds, it's ready.

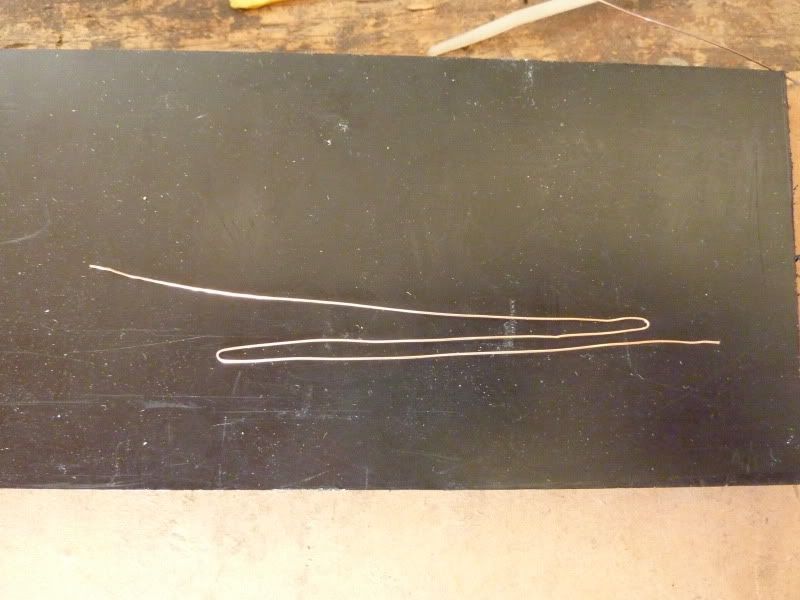

On HDPE welding equipment. After a few failed attempts with cheaper hot air guns and self build nozzles I got myself a second handLeister Triac S. Still not cheap.... But worth the investment. As the Hannibalito's demonstrate.

Originally posted by Liftoff

The tool I used was a combination machine. A mirror welder but with attachments for wire-welding.

For mirror welding (the mirror is a polished stainless steel plate). Put the tubes in the hydraulic clamps. Scan the barcode of the parts. The parts get pressed at a certain pressure against the mirror. The mirror gets heated to a certain temperature. When the parts have the temperature desired, the mirror is withdrawn, and the clamps press the parts together. Never seen neater butt-joints.

Wire welding requires elbows and straight connection pieces with the wire in them. But the idea is about the same. Push the cleaned parts together, align. Push the wire-connectors from the machine on the studs on the parts, scan the bar code, and press start. When the buzzer sounds, it's ready.

On HDPE welding equipment. After a few failed attempts with cheaper hot air guns and self build nozzles I got myself a second handLeister Triac S. Still not cheap.... But worth the investment. As the Hannibalito's demonstrate.

)

)

Comment