Re: Liftoff (FW) build diary

Now that's a coincidence!!

Yeah, we'll meet up but, but not our machines.

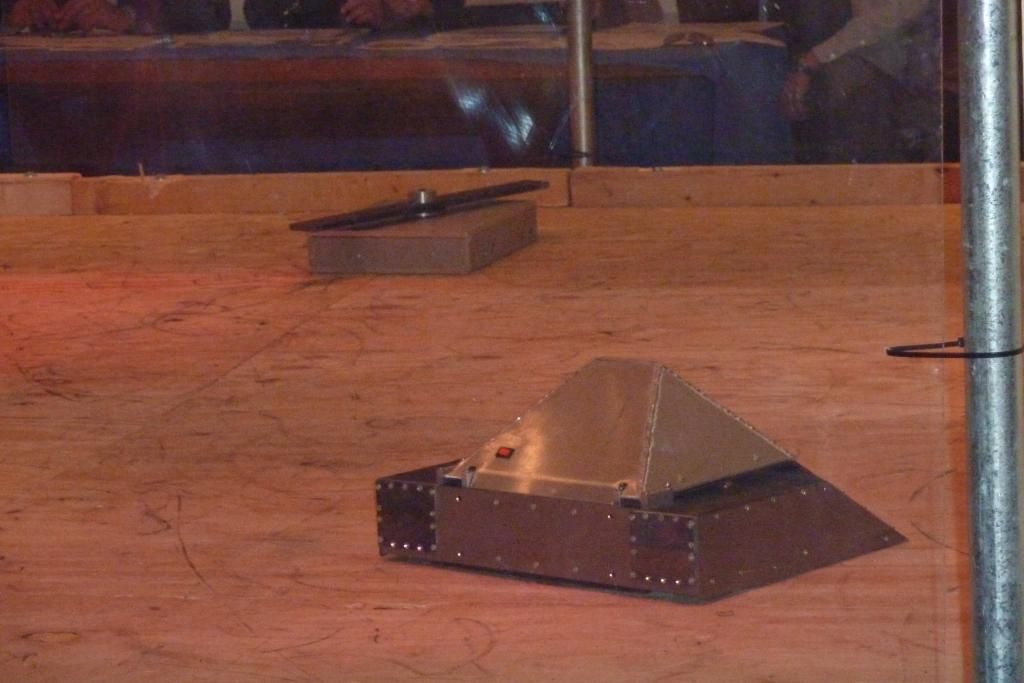

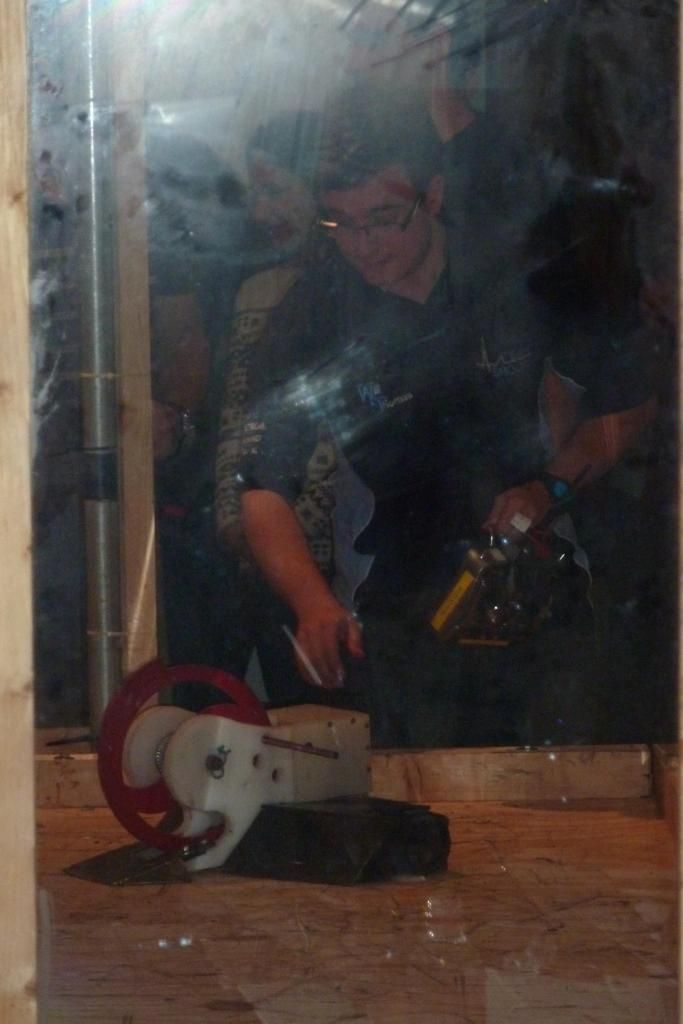

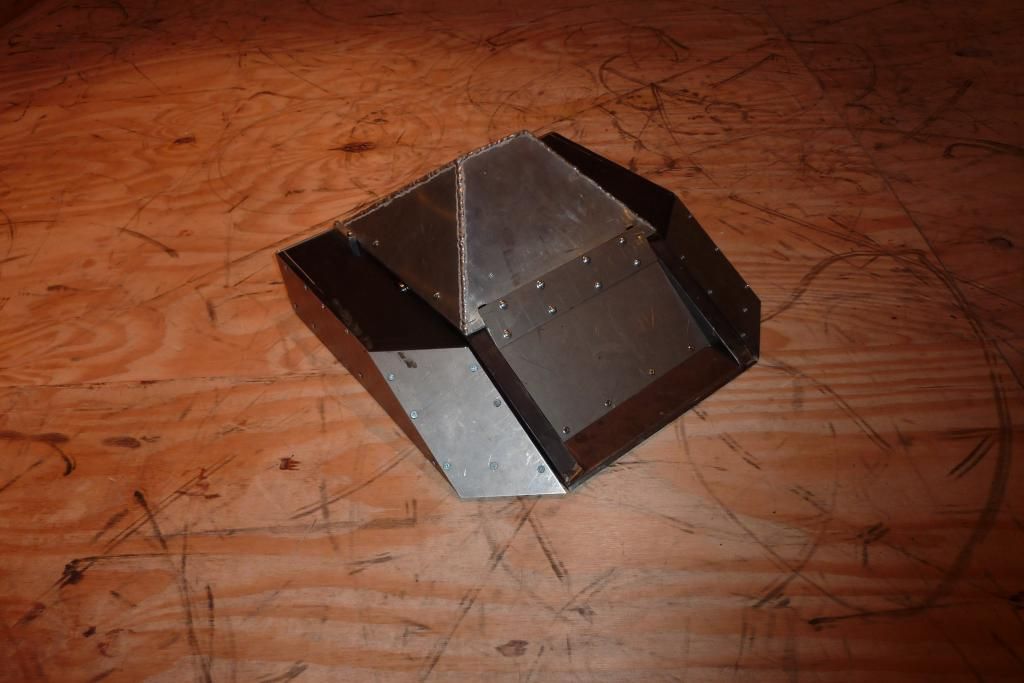

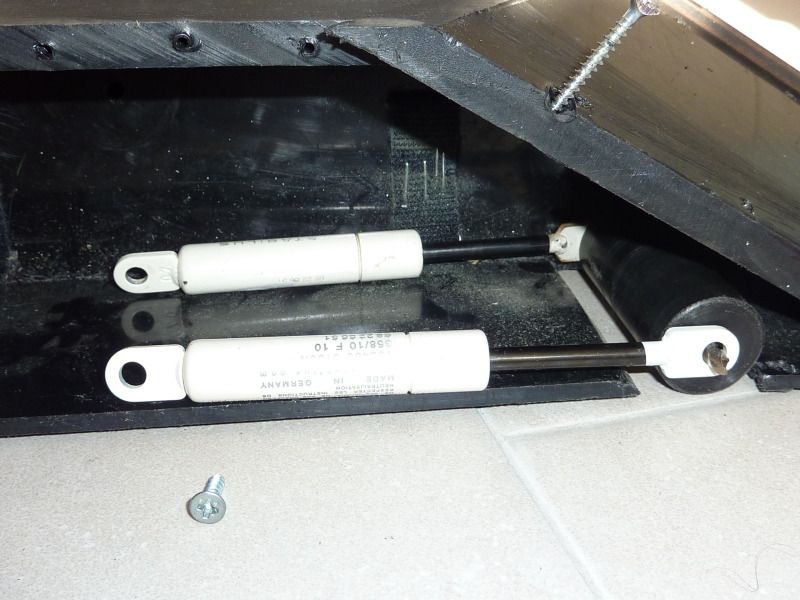

Final adjustments ready, and its working fine now...more photos and vid clips after the event...

Now that's a coincidence!!

Yeah, we'll meet up but, but not our machines.

Final adjustments ready, and its working fine now...more photos and vid clips after the event...

Comment