I've been using chain and sprocket reduction on my robot Vendetta for about 3 years. It has sometimes been giving me trouble but I have managed to get rid of most of the bugs. However at our Nationals on the weekend I destroyed all off my 250W scooter motors, so I think its time for a new idea.I built a beetleweight to test out-runner brushless motors in drive and a had some success. My plan was to scale it up into drive for Vendetta. The problem is I have never worked with gears before and am unsure what size MOD to choose. I'm thinking of using an 80 tooth MOD 1 bored out and welded onto my 250mm trolly wheel hubs with a 12 tooth pinon driving it from an interal gearbox made from ebay angle grinder bevel gear sets. Total reduction 16.7:1. I plan to use NTM 42-58 500kV / 1300W brushless motors with 6-cell LiPo. Does my choice of gears sound strong enough? Would I need an extra reduction stage?

Announcement

Collapse

No announcement yet.

Drive gear size

Collapse

X

-

Re: Drive gear size

31 km/h. If the brushless have the torque to get it moving, it will be fast.

With the right speedo, you could have a suitable setup.

But with a Z90-12 secundary gearing (18.75 -1 ratio total) top speed will be 27.5km/h

The max advisable secundary gearratio is Z96-12 (20-1) and you still have 26 km/h

I know what I would choose.

-

Re: Drive gear size

Daniel

interesting question line. Been looking at the same thing and there are alot of angle grinder gears on eBay, though I was looking at smaller wheels

The Australians seem to be into testing brushless motors as well for feathers

Comment

-

Re: Drive gear size

Yep, I'm one of those Australians. My beetle weight brushless test drive worked, so its time to scale up. The problem is there has never been an Australian robot with a custom gear drive. We always use pre-built gearboxes or chains, so I have no experiance to draw from about what Mod gears can transfer that much power. I've seen a lot of european robots with custom gearboxes, so I guess this is the best place to draw experiance. Gears here are stupidly expensive, so much that it'll be cheaper to buy from Technobots, so I want to smallest gears that'll handle the drive. The current option that I've been modeling in Inventor has 12:30 spur gear first stage (ebay RC car pinons?) + 14:35 angle grinder set + 20:80 spur gear. Possible MOD 1 for the spur gears. Total reduction 25:1 and a no load speed of 5.8m/s. Sound good to you guys?

Comment

-

Re: Drive gear size

The tricky bit is the gearbox for sure. I quite like the thought of the engineering challenge but then its sitting in a fighting robot that someone is going to smash into - simple and easily fixed/replaced comes to mind.

The alternative is to try and couple the motor to something like a Banebots gearbox http://banebots.com/c/P60K-S7

Comment

-

Re: Drive gear size

Ok, 2 stage, MOD 1, wider then 8mm. Go for the 8.69m/s (31km/h). Thanks guys. I prefer to use m/s because our arena is 4.8m and I can gauge off that.

I can't drop in a pre-built gearbox because I'm using an old chassis. That chassis is made from 5mm wear plate and has taken a lot of hits from spinners with no damage, so I can't see any reason to chuck it in the bin. Its only as wide as 2 x 300W scooter motors, which makes it all a challenge.

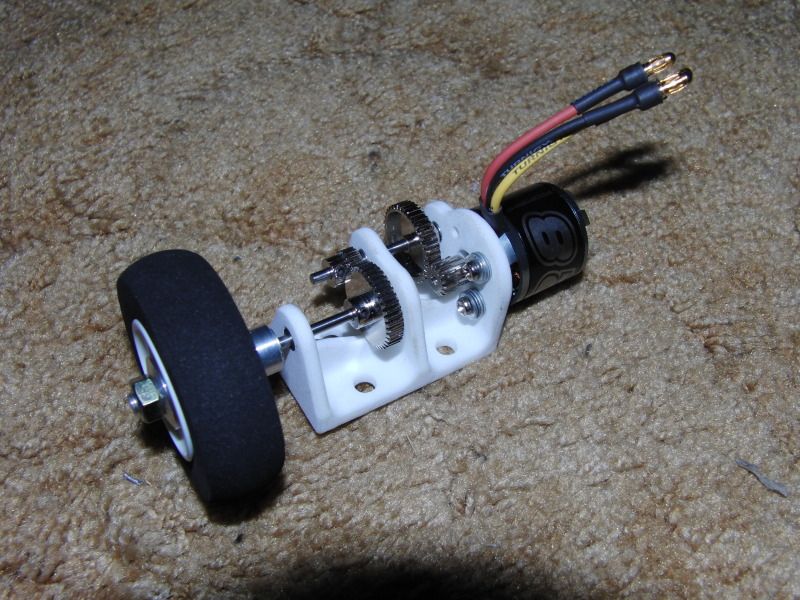

Second question. In my beetle weight brushless gearbox I used Shapeways to print the gearbox housing which I then bolted into a biscuit tin. I was plaining to use the same thing in Vendetta, with a 3D printed housing that matched the scooter motor bolt pattern.

Here's a piccy of what I did with the beetle.

Comment

Comment