Cut out the second wheel slot today. Garage was freezing but made good progress none the less.

IMG_20180120_124339.jpg

Drilled some fix holes in the base for the weapon motor.

IMG_20180120_134051.jpg

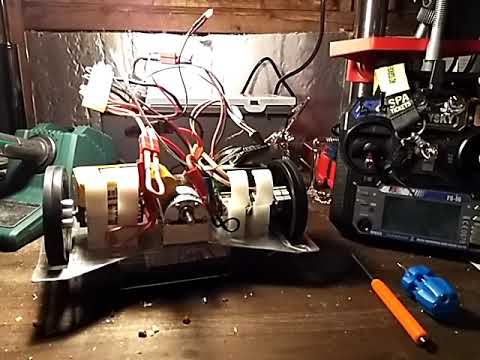

Then I laid up some parts to check it will all fit together/ Never know if the drawing and reality will match.

IMG_20180120_135046.jpg

I noticed one of the motors is branded as Actobotics and the other is another brand but same part numbers. Will check it matches.

IMG_20180120_094626.jpg

Shocked at how small these little motors are.

Weighed every things and also measured some parts to check dimensions are as expected. Most things are coming in a little lighter. Not sure if that is my scales though.

IMG_20180120_124339.jpg

Drilled some fix holes in the base for the weapon motor.

IMG_20180120_134051.jpg

Then I laid up some parts to check it will all fit together/ Never know if the drawing and reality will match.

IMG_20180120_135046.jpg

I noticed one of the motors is branded as Actobotics and the other is another brand but same part numbers. Will check it matches.

IMG_20180120_094626.jpg

Shocked at how small these little motors are.

Weighed every things and also measured some parts to check dimensions are as expected. Most things are coming in a little lighter. Not sure if that is my scales though.

Comment