I've got a big pull down circular saw that I use to cut hdpe, means I can get it neat and fairly accurate. If you ever need any bits cutting drop me a PM, as long as you supply the material and pay postage I'm more than happy to do it.

Announcement

Collapse

No announcement yet.

Hatchet 2

Collapse

X

-

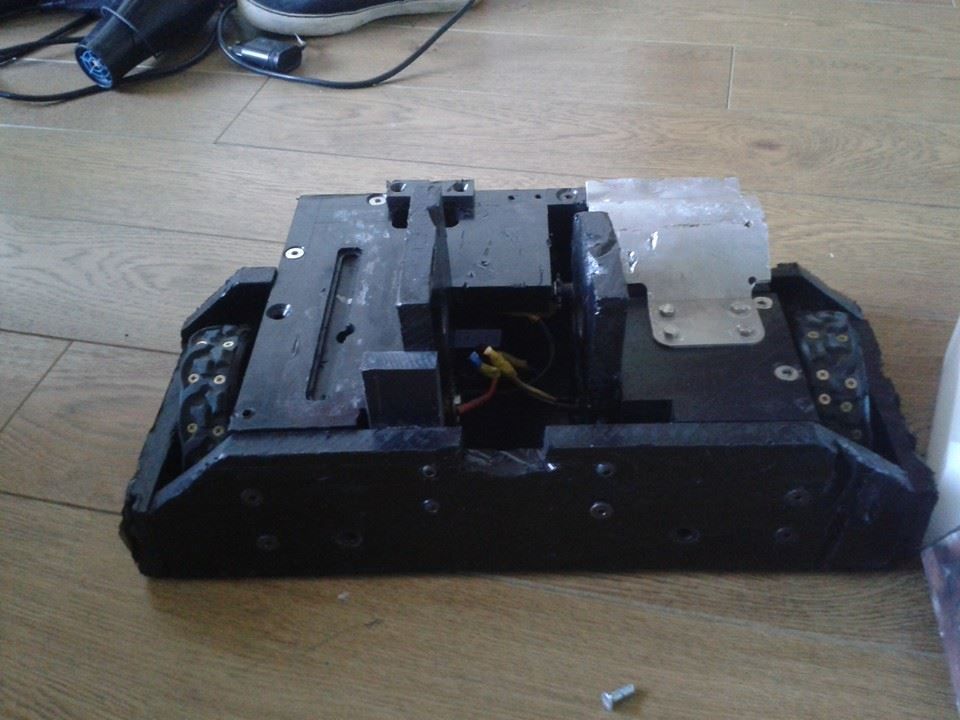

More progress on Hatchet, managed to get most of the body bolted together before i ran out of bolts (well that was silly wasn't it). I've also managed to somehow lose any kind of countersink bit so until the new one turns up they all just kind of stick out. Other than that though it's going together really well, i might actually have a working robot well before Whitwick which will be it's first outing.

Comment

-

Updates!

It's been a productive week or so for me, after finding out that Hatchet is in the World Champs i decided to throw myself into finishing it so i have plenty of time for testing, but first i needed to buy the old robot back from Alex...so that's what i did. Ian was kind enough to drop it down on his way to Robochallenge and i quickly set about removing anything of use, this included the axe, scoop, 3 30a Electronize and a Park BEC. I then decided to leave the old girl alone and focus on the new one, i ordered a crap load of parts, 2 2200mah lipo's ( 5 and 6s), 2 new 8mm sprockets (8 and 40 tooth), some heavy duty 8mm chain, a brand new 300w scooter motor and an Imax B6 charger. With my bank account feeling the full force of a robot induced craze i set about working on the actual robot, as i'm still waiting for a few bits and pieces to come i haven't got as far as i had hoped but Hey 3 months is loads of time right......? The drives have been mounted, one bulkhead has been cut to accommodate the axe motor and all holes are thoroughly counter sunk. If you managed to sit through all of that well done you.....here's some pics for your trouble.

Comment

-

Huge amount of progress today, got the scooter motor and axe set up mounted and finished off the electronics. The electronize for the drive may be going in favor of some borrowed Tz85's from Hardwired 2 (thank you Matt). I did manage a little axe test at 5s and a couple of things became apparent, the weapon is much more powerful than last year causing the machine to jump violently when it fires, the sprocket on them motor however has a habit of coming off, there's a grub screw holding it on and it keeps letting go. To hopefully fix this i've ground a flat on the shaft and used massive amounts of Loctite to hopefully keep the screw in place.

Comment

-

And I'm all out of gum

On a side note Hatchet broke itself, the troublesome grub screw that I thought I had fixed decided it would carry on turning on the shaft regardless of how tight it was and has just cut a massive gouge all the way round. I'm working on trying to have the sprocket welded on but that may have to wait a while, the axe is out of commission for now though.

Comment

-

Hatchet's all up and running again after the whole *grubscrew eating the motor shaft* thing, had the sprocket welded onto a new motor (350w this time instead of 300) and that seems to have sorted it. Managed a little video, just to clear it up the axe doesn't actually hit the floor because it's travel is stopped by the front bulkhead about 5mm from the ground. https://www.facebook.com/video.php?v=346043228929766

Comment

Comment