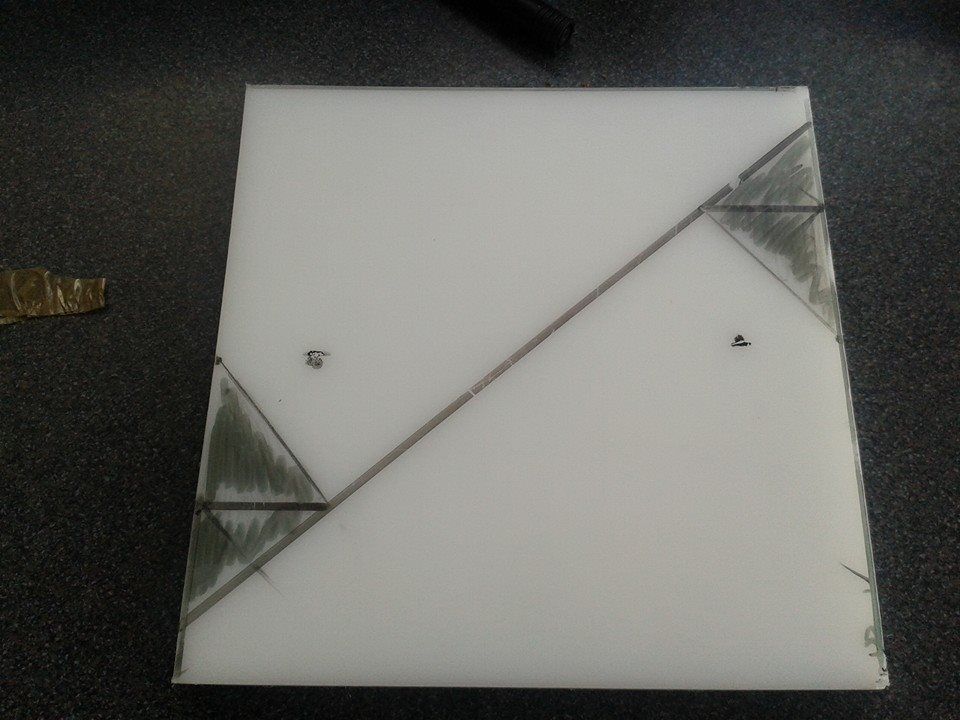

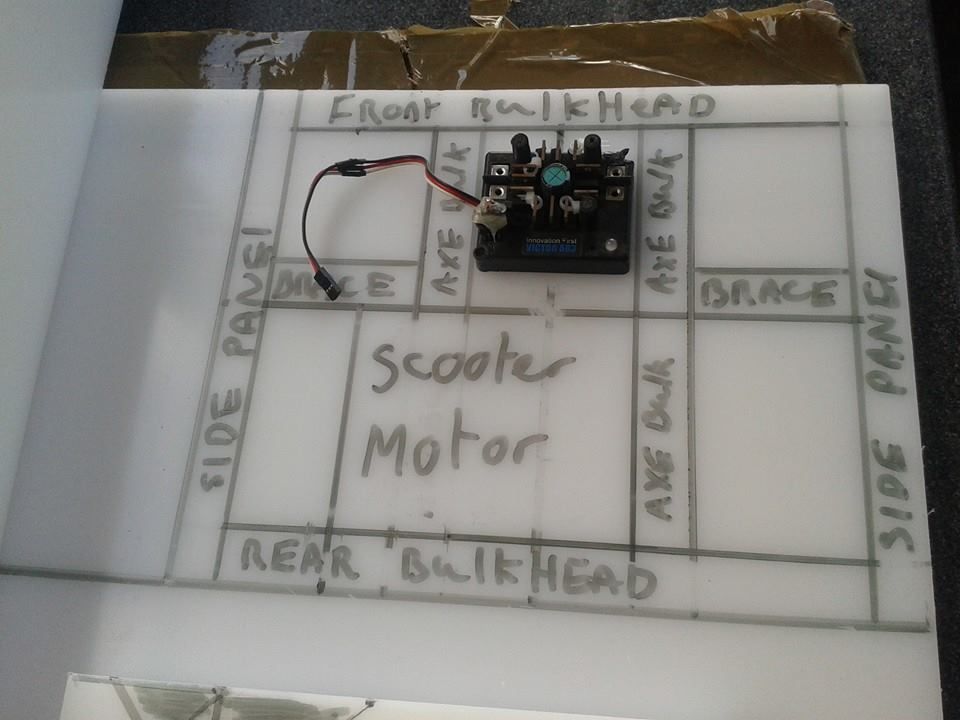

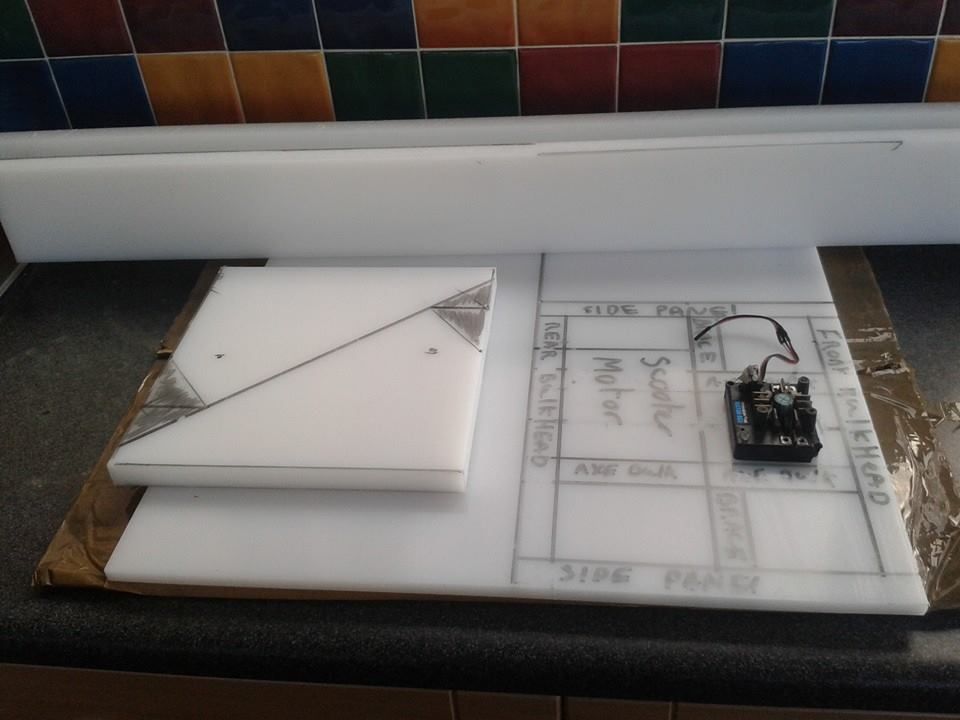

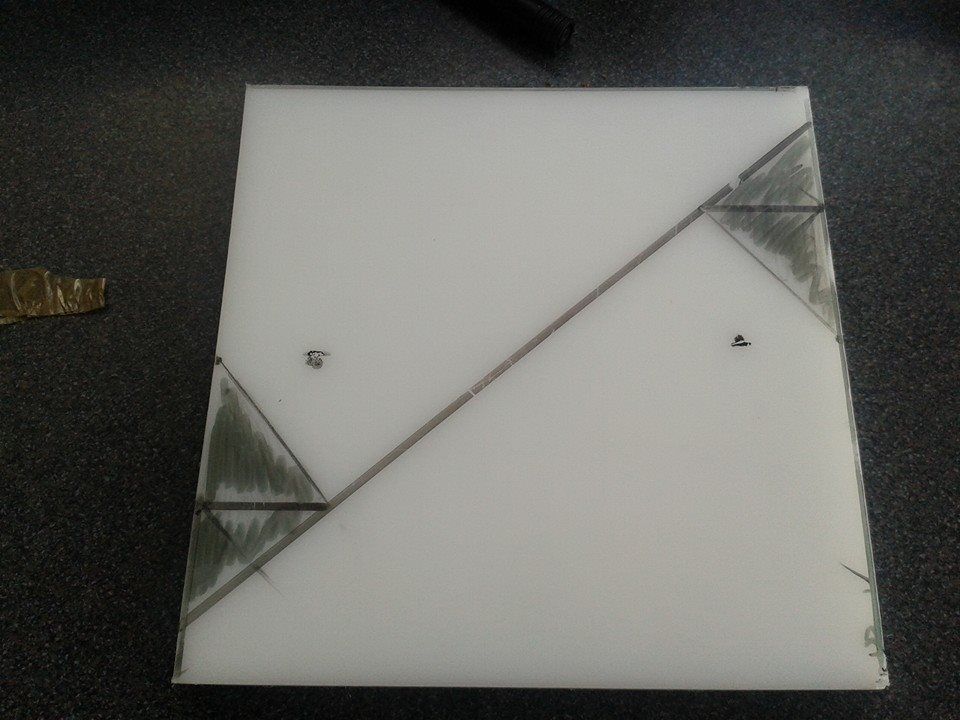

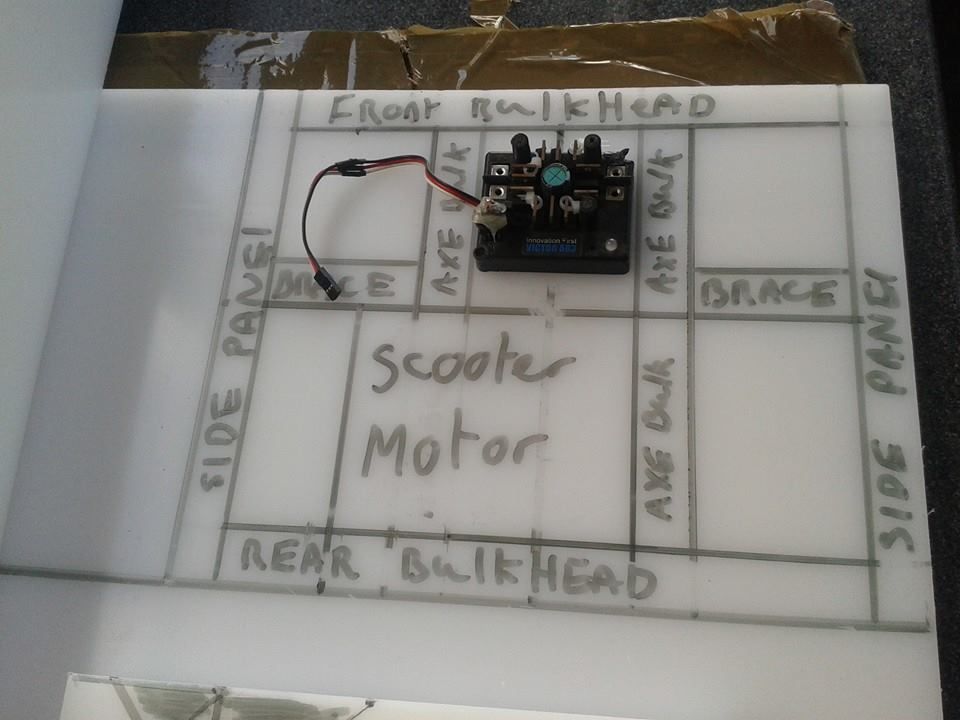

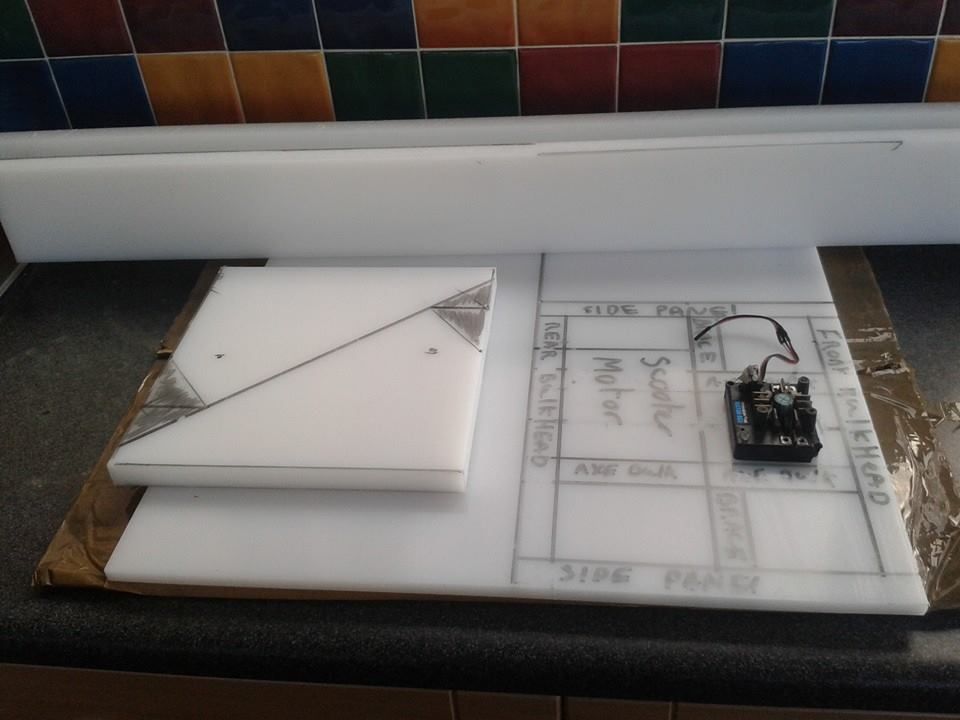

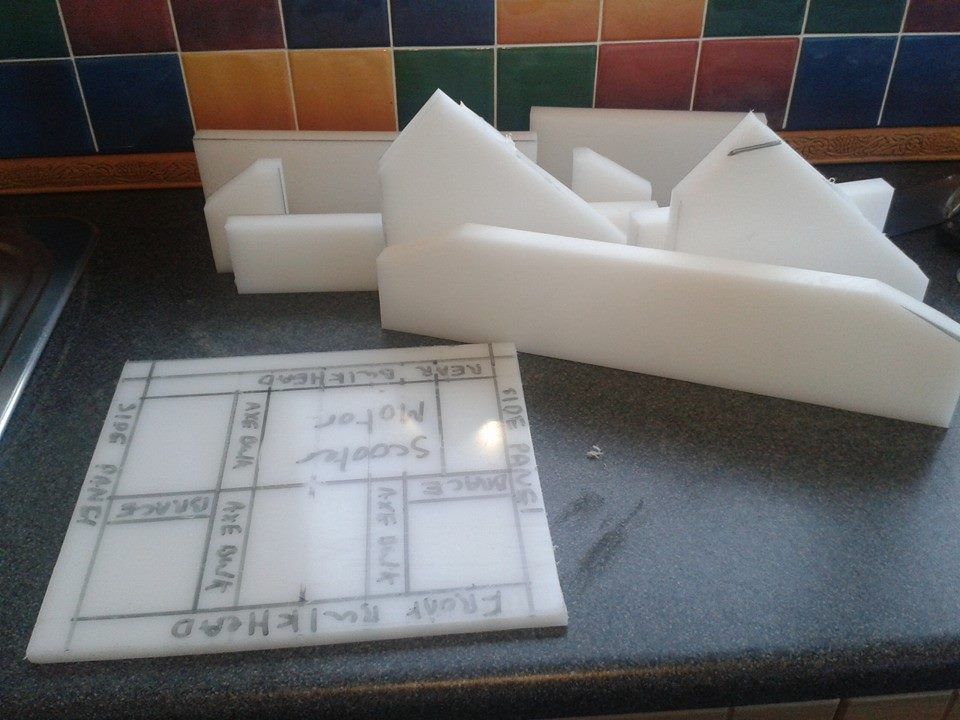

I couldn't be bothered to trawl back through to find the original thread for hatchet so here's a brand new spiffy one for you. Decided i may as well build a new hatchet and at least try and get it to the champs this year if it gets picked, with that in mind i've taken a good month or so of design time trying to keep what was good and discard the rest. The only real thing that i've kept the same is the axe and scoop set up, the shape is roughly the same with a few improvements (nicer looking bulkheads, better weight distribution/wheel placement and a slightly bigger chassis). the new body is now 20mm thick Hdpe with a 10mm base seeing as i got a really good deal on some offcuts that i just couldn't say no to. I don't want to overload you all with information at this point so here's a couple of teaser pics to make the reading worthwhile.

and yes.......it's white now... big whoop you want a fight about it?

and yes.......it's white now... big whoop you want a fight about it?

and yes.......it's white now... big whoop you want a fight about it?

and yes.......it's white now... big whoop you want a fight about it?

Comment