For Hardox give Pegasus Profiles or JL Steel a try.

Announcement

Collapse

No announcement yet.

HardWired II

Collapse

X

-

Cheers! Going to have a good look when I can, get some progress made. Speaking of which...

Actual work has been done on HardWired 2!

Cad work, but I've got somewhere with it nonetheless!

http://i1355.photobucket.com/albums/...pse1b00311.jpg

http://i1355.photobucket.com/albums/...psb31671b6.png

140mm-ish OD, huge hole in the middle is for a 47mm OD roller bearing, but also have done a design that's been adjusted to take smaller and/or simpler ones because I don't have a great load of engineering expertise so the simpler the better! (He says, designing a single toothed spinner). Takes a 20mm dead shaft too, with the bearing being in the disc. The bulkheads are going to be bolted to the hardox chassis extensively, but a bit extra strength doesn't harm!

Centre of gravity somehow is spot-on, and it's been designed with 10mm hardox in mind as material, but I'm definitely considering upping that to 20. Rough calculations of weight come out at about 800/900g (with the bearing holders bolted on) which is admittedly a little on the light side but it'll probably help with spinup time. Failing that again, can double it to put it much closer to 2kg.

Still a bit of tweaking to do, but it's progress! Soon as I hear word back as to whether I've made it into the world champs, I'll get it all cut and whatnot.

Comment

-

Nice!

Put a heavy fillet where the base of the tooth joins the outer circumeference of the disk and also put a small (1-2mm) fillet on the tip of the tooth. They will absolutely break off/round off otherwise.

Definitely pad out the weight to 2kg if you can. 140mm OD at 900g Probably wont do much but nibble harmlessly on the opposition :P

How are you planning to machine the disk center for a bearing? And what keeps the disk attached to said bearing? Machining the hardox out will be very difficult.

Comment

-

What Glen said. I traced the design and ran some stress analysis with some mods:

The original shape with 20mm thickness:

As expected, the base of the tooth has plenty of stress and there is also some stress building up around the largest hole behind the tooth.

A modified shape with a small radius:

The small radius (about 5mm) doesn't do much to reduce stress. I made the two balancing holes a more equal size, which definitely reduces stress in that area.

The same thing with a large radius:

The large radius definitely helps! Another stress reducing change would be to reduce the hight of the tooth. I imaging you want to spin the disk pretty fast, so the tooth will never use all of that bite depth.Attached Files

Comment

-

Great, thanks for the input! Thanks for those pictures too Nick, definitely helps to see the effects that has - what program's that one too you've used? Seems extremely useful for ensuring things won't dissolve upon impact haha. Will definitely up it to 20mm then as well Glen - not sure I'd like to just be scratching the paintwork given what I could be up against haha

I uploaded these at 4am and in my tiredness I appear to have forgotten about the bearings... I had planned to bolt on essentially hardox washers (with 4x8mm bolts straight through the disc) to keep the bearings in then loctite the bearing onto the disc itself maybe? I'll try and cad on what I mean, but on one side there'd be a small hardox disc of about maybe 70mm diameter, 3mm thick and on the other side I'd have an aluminium pulley again (of roughly the same size) bolted on. Not sure how many other ways there are to do it with a dead shaft if I'm honest, though I may be missing something there...

Also, as for the tooth depth, I don't think I will use all of it but I'm trying to get the machine to be pretty fast and drive into stuff at speed, try and get some nice engagements where possible! Though, I could certainly drop the tooth size and then scale the whole thing up a little to add more weight... Might have a go at making one like that to see how it might work out! How much bite is preferable for this sort of thing? I seem to have 20mm in my head as a 'good' figure but part of me's thinking now that's a ridiculously huge amount...Last edited by Flag Captured; 15 January 2015, 16:40.

Comment

-

I use Rhino 5 with an add-on called Scan & solve to do the stress analysis - its not the best tool out there but it is dead easy to use.

With the bearing, you might be better off to use a double row ball bearing rather than a single tapered roller bearing. Rollers are generally used in pairs as they only resist sideways forces in one direction and they need tensioning to stay together. A 3204 double ball bearing has more than twice the radial load capacity than the same sized roller bearing and is 20.6mm wide - a good match to your disk. A pair of roller bearings are about 30.5mm wide, which will make the hub design difficult & bulky. Get bearings with metal shields rather than plastic seals as they have less friction and run cooler at high speeds.

What sort of RPM are you planning for the disk? At 10,000 RPM and a 10 KMH forward speed, the disk will get a 16.67 mm deep bite and since most impacts happen at relatively slower speeds, a tooth depth of around 16mm should be more than enough. A smaller tooth will be stronger and lets you add weight, never a bad thing. Since the disk is fairly light and a smaller diameter, your best option for big impacts it a really high RPM; the kinetic energy increases with the square of the speed, so even a modest increase in the RPM can really improve performance.

Comment

-

If it's easy, it sounds good to me haha!

Ahh I see what you mean too there, probably best then! Will have a look at a pair of those when I've finalised the design and everything.

And RPM-wise, I'd like about 12,500 and upwards really, I'd like to go even higher than that but I do realise that the faster it goes, the more powerful the motor needs to be and I haven't got a whole lot of space/money left for super high amp output/bigger batteries and the like. Got an NTM 5050 in mind, and with a bit of creativity I think I can just about get it to do that on 6s, assuming I get two 3S packs and wire them to give 2x3S and a 6s output. I will certainly try that too!

Problem is with a high RPM that I guess it makes it more difficult to get a bite? So I'm trying to give it the best chance possible by design as I can! I'd love to get something really consistent but also heavy hitting when I want it to be, but as long as it does a bit of damage and maybe might get a robot out of the arena all is fine by me!

Comment

-

An NTM 5050-580 is probably not going to give you 12.5K RPM on a 6S pack. It's no load speed is under 13K RPM so unless you gear it up, friction will reduce the disk speed to around 10K. Gearing up has it's own problems; slow spin-up, higher current draw, etc.

You might do better with this SK3 motor: http://www.hobbyking.com/hobbyking/s...ize_heli_.html The higher KV means you can gear down a little to get extra torque and reduced spin-up time and still hit the speed you want. The SK3 motors are supposed to be as well made as the NTM models and this motor is only 6mm longer than the NTM 5050

Comment

-

Hmm that one doesn't seem too bad... I'd imagine I'd need 8S for it though as per the stat sheet, couldn't get away with 6S? Problem I'm having really is fitting the batteries in, any that are quite small for their capacity are the expensive brands which I can't quite afford at the minute! (plus a HV ESC)

Definitely seems a bit nicer an option though!

Comment

-

It will still work fine at 6S except the power will be reduced from the peak 3,700W. I worked out the weight of your 20mm thick disk to be roughly 1.6Kg, so my gut feeling is that the motor will still have enough power. The other option is something like the Hacker A50-8S Turnado V3 motor that I use in Mr Mangle or a Scorpion HKIII-4025-890; they will will give you more power but at three times the price. Its surprisingly difficult to find high KV 50mm out-runner motors; these three brands are the only ones I know of.

Comment

-

I can live with that, might be a little bit more of a strain but if it spins it it'll be fine I hope! Yeah weight wise I got about 1.7kg on my version, so that definitely sounds about right, it's not high MOI either so should be alright with any luck! I can up the voltage again, but I'll have to get amazingly creative with the internal space - as it stands, I need to get 2 3S batteries with enough capacity to run the system, that can fit in the space of about 2 1/2 drill motors...

I would go for something like that but cost is a bother. That, and I'd rather have a motor and two backups than one super costly motor, just because of my talent I guess you can call it for breaking things that shouldn't otherwise get broken haha

Comment

-

I agree. I just mentioned the other $$$ motors to show the rather limited options. The Scorpion motor might be a good upgrade later on if you are really happy with the design. Its probably best to keep the voltage at 6S to avoid melting the drive motors.

Comment

-

Yeah it does prove the point pretty well! I mean, if budget wasn't as restrictive as it is I'd almost definitely buy one of those more expensive motors but unfortunately can't be done this time...

Definitely too - if I can get the drive motors to run off 3S with that parallel LiPo trick to get 3S and 6S output that'd be fine - the motors themselves will take 4S but I do worry about them causing damage to themselves or the gearboxes at that point!

Comment

-

Work's beginning on HW2O this week, going to make some 20mm HDPE bulkheads to see how they fit primarily (judge how much space 20mm bulkheads would take up), but also as a backup in case I can't get the aluminium ones made, given I don't have the tools to do anything with it really... Could CNC them but I'm not made of money haha!

Not 100% on how to make them take a dead shaft solidly enough, but I'll cross that bridge when I get to it I guess

Comment

-

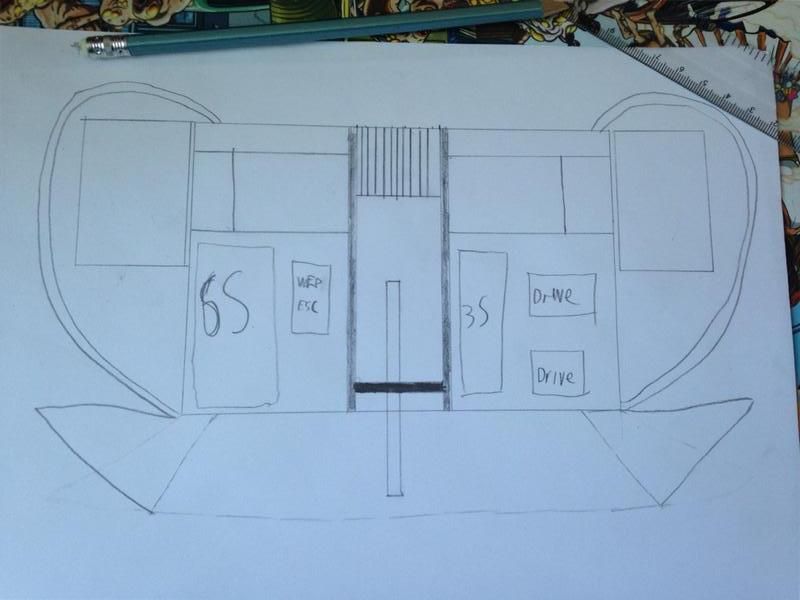

After trying too much to tetris in parts to a tiny little machine that was clearly not intended to have a spinner on it, I've decided to just go for it and do a total rebuild for Overdrive. It works out at about 30 quid in materials, plus whatever it ends up costing me for a new scoop so not -too- painful on the budget. It also looks rather different (took a bit of inspiration from Algos, the beetleweight) but here's the rough plan

My intention is to possibly shorten it a little again, to save on that massive amount of dead space but I need to know the sizes of all the parts properly before I can make that call. At current spec, the main body is about 375 wide and about 250 long, I'm 90% sure that'll shrink a little again but again, just waiting on sizes of parts. The chassis is aluminium though now, 15mm 6082 from Aluminium Warehouse and maybe some hardox brackets to shield the edges given I'm probably end-jointing it (no idea what the technical term is). Those curved bits are HDPE too, not sure if I'll keep those though... I'm playing about with ideas that would add some angled hdpe to the sides to stop those pesky drums haha. Any thoughts on the design so far would be much appreciated too!

Should hopefully now be able to get underway with this, now that design problem's over. I'm buying a pair of GR01s too so that the original HardWired 2 will be able to fight in whiteboards and stuff so that'll be fun!

Comment

Comment