Announcement

Collapse

No announcement yet.

Boring Brick

Collapse

X

-

Being such a small piece is definitely a worry, the baseplate is only A4 size so if it takes a big hit it's not going to flex too much, i imagine it would take a pretty big impact to do anything meaningful though.

-

My only worry would be the fact that it's on a smaller frame, hence it's got less of a chance to bend and absorb the impact but I'm sure it'll be fine!

Leave a comment:

-

Don't worry, when I had SMIDSY I had a 10mm polycarb top on and thor took a nice hit. Made some dents but it didn't crack so you should be fine

Leave a comment:

-

I'll be ordering spares, maybe go up to 11 or 12mm just in case the current one isn't up to it, i remember Jamie (drumroll) saying that he used 6mm for the top of drumroll and the only thing to get through was a hydraulic crusher. The only bits i can see being a problem are the mounting points but hopefully it'll be fine.

Leave a comment:

-

9mm might be a little on the thin side from some of the hammers and axes this year from the looks of things, so I'd have a backup just in case (maybe make a spare HDPE top plate in case the polycarb cracks?) but other than that, good stuff!

Also, should note: I don't have a lot of experience with polycarb, so I can't say for sure how it handles, it's just what I've heard from what I've seen on here, really. I'm fairly sure I've seen a machine using 20mm Polycarb and that was pretty tough...

Leave a comment:

-

Yea polycarb for the lid as well , the baseplate piece is 9mm and the top will be about the same, hopefully it will hold up

Leave a comment:

-

Nice one! 10/10 for using Polycarb, are you using it for the top armour as well?

Leave a comment:

-

To be honest I have no idea, I brought them from another roboteer along with the batteries and electronize, and thanks the build has definitely had it's ups and downs so far but it's getting there, going to be a squeeze to get the axe mechanism in there though.Last edited by mrsam; 27 February 2014, 19:17.

Leave a comment:

-

Just watched the vid and looks like its coming along nicely =)

B&Q drill motors by any chance?

Leave a comment:

-

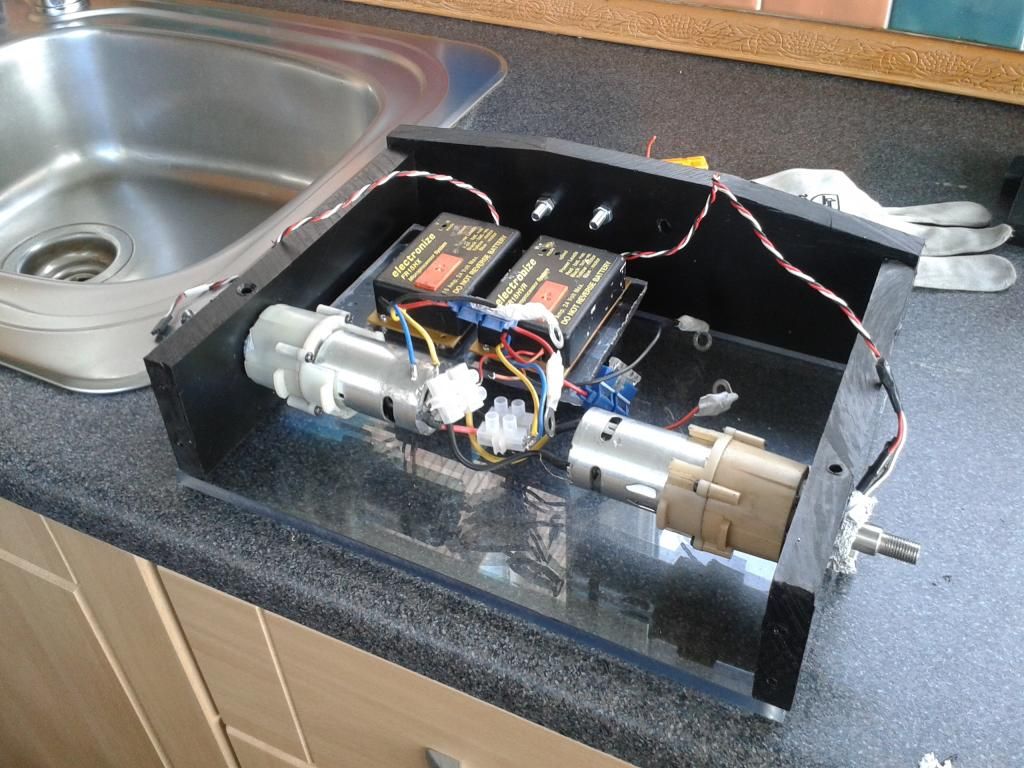

Made a start on bolting the chassis together today with much better bolts ( the old ones were made of some horribly cheap weak metal). Apologies for all of the wires floating around it'll look much neater when it's done.

Leave a comment:

-

Done some more today, got the escs and batteries mounted, started the final wiring. Also made a start on bolting the chassis together but had a few problems with shite screws ( I've got two stuck in my polycarbonate baseplate that snapped off whilst getting tightened) so I've ordered some high tensile ones that should be much better. Pics to follow in a couple of days

Leave a comment:

-

Don't overdo. It's just steel, with piece of 6mm hardox as axehead.

Leave a comment:

Leave a comment: