Ah, I see. A bit ironic, with the spear shape of the hammer ones, but I'd prefer the others anyway. Gives some space, and makes things flatter. And neater.

Announcement

Collapse

No announcement yet.

Team Pasty Build Diary: Loki

Collapse

X

-

i think nylon is suppose to be a good runner material

these would also do the job

http://www.technobotsonline.com/?sub...roducts.search

Comment

-

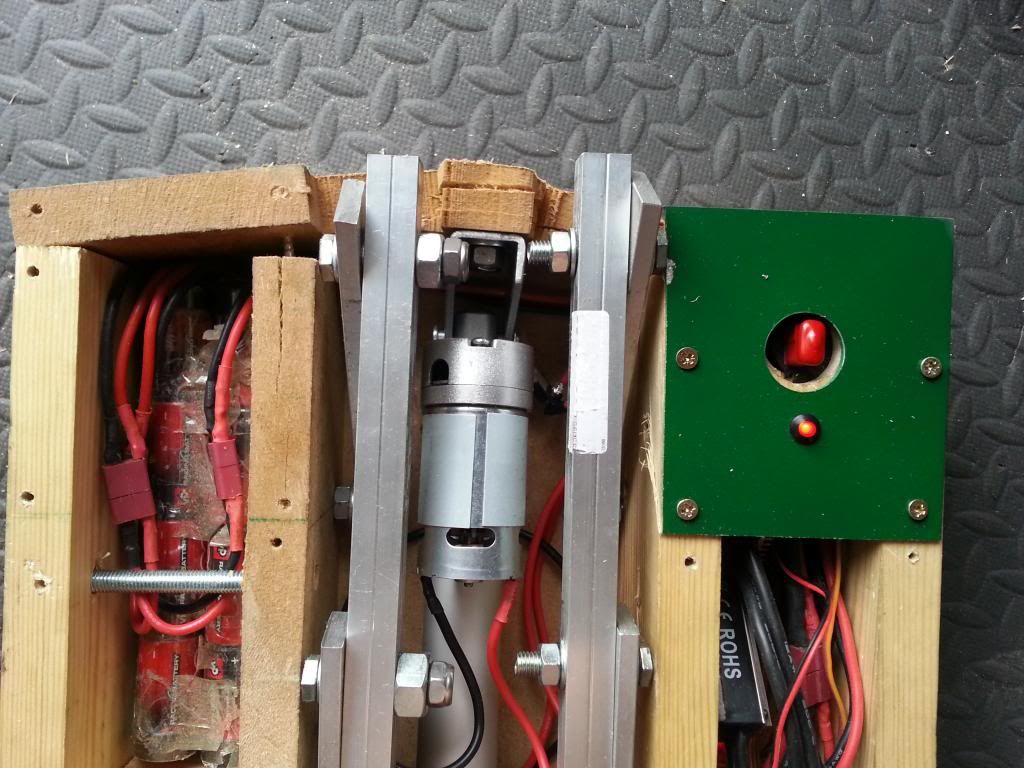

Been a busy roboteer today, I now have a working four bar mechanism Limit switch in the down position is working well, needs a slight adjustment.

Limit switch in the down position is working well, needs a slight adjustment.

I attempted to self right to see if it would, it failed the first time and then the MDF gave way and it had a bit of a rear end prolapse :S

Going to try making the rear bars longer to see if this will facilitate self righting.

But apart from that it seems to work well, here's a couple of videos of it topless (!), having a little run around.

And some photos:

The tape is a substitute for welding just to hold things together for the time being.

Comment

-

It's not really the length of the arms that's crucial, it's more then distance between the holes for the bolts. I lined them up by taping the bars together and then used a pillar drill to drill both at the same time so should be identical. Don't know if that's the best way but seems to have done the trick.

Comment

-

Had a play around with the postion of the arms to try and get it to self right, and here's the result of self righting take 2:

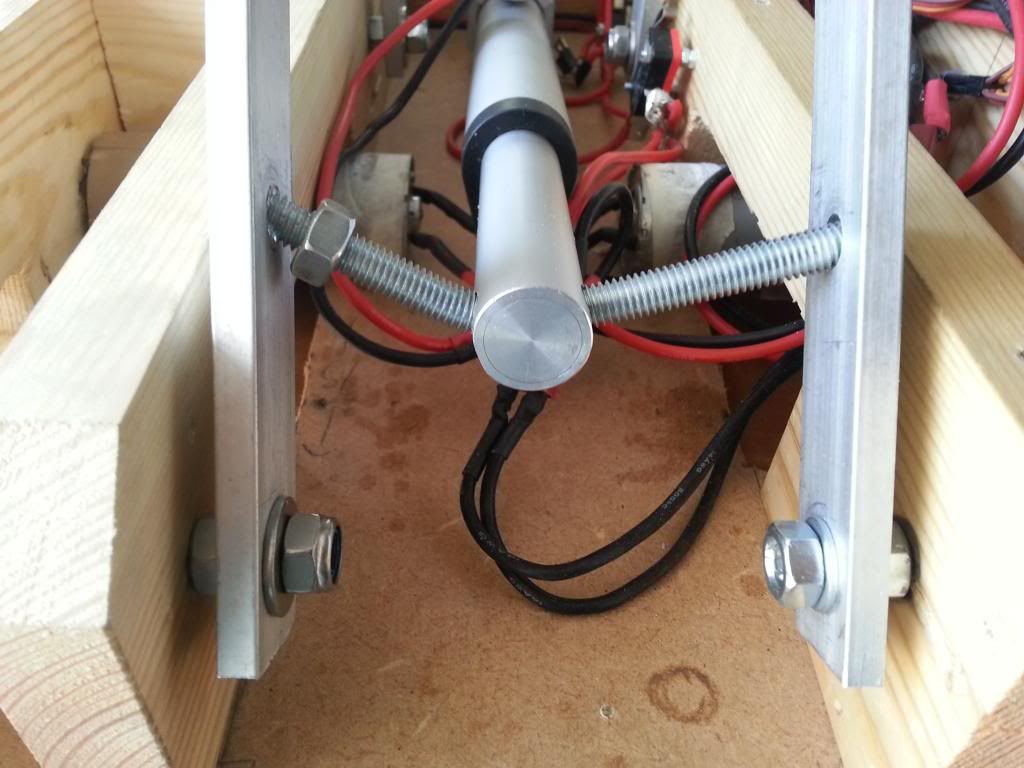

Going to have to upgrade to M10!I think I know why it's not self righting but I'm going to need to get more box section to sort it out.

Also replaced the back and added diagonals to the sides for more protection.

Getting excited for Newport

Comment

-

Unless it's currently all tight, not really. That actuator should have plenty of push, would probably move the lifter even if you tightened all of the bolts down!

Also I agree with Dave, that main bolt takes all of the stresses going through the lifter, make sure it's a good deal stronger than your previous setup.

Look forward to seeing this in the arena, keep it up.

Comment

-

I'll try that Dave, thanks Thought that bolt might be strong enough but apparently not lol. Oh well, learning all the time!

Thought that bolt might be strong enough but apparently not lol. Oh well, learning all the time!

Yeah Josh the joints are all loose enough the rotate and held in place with Nyloc nuts. It's the force of what it's trying to lift pushing in the opposite direction that the actuator is trying to move in.

Thanks Ellis, I look forward to meeting Tormenta 2 for a scrap one day

Comment

-

Instead of even threading the rod, you could use the largest size rod you can find and use a few shaft collars to keep the shaft centered and align the actuator, sorta like what I did on my bot Nyx ( http://nearchaos.net/nyxhighres.jpg ) but instead of the middle two collars holding the weapon in place, they'd keep the actuator centered.

Comment

Comment