Only useful thing I can suggest is recalibration if you've not already done it. Or have a close look at the PCB tracks and all connections to see if there's any damage or swarf on the board causing a short circuit. Can't think of much else I'm afraid.

Announcement

Collapse

No announcement yet.

Team Expat - Beetleweight Adventures

Collapse

X

-

Forgot to update this!

I arrived at Harry's and we got busy breathing life into Gonzales. He did all of the wiring, as I've never really done much wiring myself and figured he'd do a much better job, which he did. We did several tests in his shed and managed to get the gyro working. Phwoar that felt good, it drove very nicely. He put forward his Scorp XL, a BEC, HDPE for a base, polycarb for the top, and I got to eat lots of bacon between times. Pretty swell guy.

Anyway, on the evening before I was due to leave, one half of the scorpion died, as the post above shows. Never got it going again, currently have new fets on their way to replace one that appears dodgy.

Thankfully, Mr. McHarg sacrificed his XL to get the thing running, and it worked perfectly. Thanks again man!

Only got a chance to "fight" 3 times at Deeside. Videos:

http://www.youtube.com/watch?v=sO646De3SYk

http://www.youtube.com/watch?v=QRTfTTIfVFI

http://www.youtube.com/watch?v=g2fajPhge1s

There were some issues, as the videos show. First was simply that guts started coming out the top, that was due to there not being enough space for all of the wiring inside. Simple fix of tightening the top a little more. Second failure was the pinion on one motor went walkies. Roughing up the shaft and some decent glue solved that ahead of the third video, where it seemed to perform without a problem.

Other problems: wiring needs to be more organised, motors got very hot, needs more LEDs.

Overall: very happy. I'm surprised it lasted. I eventually want to remake the wheels, or at least hold the tyres on better, as they began to work off the hub once or twice. Also want to put the remaining 50g into a thicker ti scoop, I can't see this one surviving a fight against 180 with its weapon blaring!

Gonzales 2 thoughts already happening gah.

Comment

-

With the Stevenage event in September now definitely featuring beetles, I have some work to do. Gonzales still works fine - I forget if I posted this on the forum:

http://youtu.be/CYIOKBvA_qs

^wish YT urls wouldn't automatically embed

- but it was built in a week or so and tapped HDPE just doesn't sit well anymore. I might put in a smaller battery to save enough weight for a strip of steel on the wedge and for some inserts/more barrel nuts. Would be nice to make new wheels out of a single bit of nylon too.

I'm also going to try and build something new between now and then. I made the first part a few weeks ago; a 12mm dead shaft:

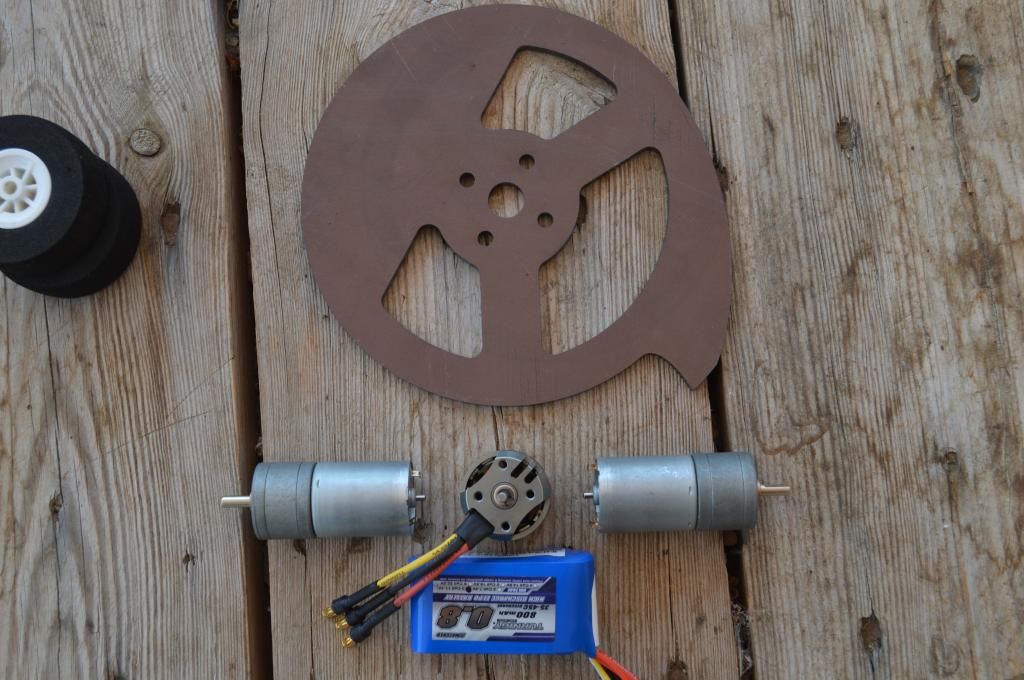

The disc I got earlier in this thread has now gone to a new home. I designed a disc for Harry's undercutter a month or two ago, but the price (thanks to Guilherme) was so good I wanted one too lol. It (they) arrived this morning.

It's 4mm hardox and 180mm diameter, which after feeling in real life I now think the weapon support materials I have won't be strong enough but it'll have to do, can't get anything else in time - only needs to last one event anyway.

The first pretendos, also giving a sense of scale:

Battery and motor are the smallest I can get away with (I think) so I can give the disc some proper support later down the line.

Got 3 machines to repair and upgrade and a 4th to actually build, aaaaaa.

Cheers.

Comment

-

That setup is pretty similar to killers, you'll love it!

https://www.youtube.com/watch?v=JMl05TaLtEE

Those little NTM motors are torquey and efficient. Even a dodgy 10c 500mah lipo at 3s seemed overkill :P Not sure what you plan to use for weapon supports but 1.2mm sawblades chopped up work great. The steel is really tough and light at those thicknesses

Comment

-

I may or may not have found out how much the 9" sawblades from a local store are...

The design I have had a load of weight left, so I think I can get 2.5mm steel supports in weight although they're pretty cut about to be light enough. I'd use 2-3mm ti in a flash, I just don't have any. Need to do a complete CAD and weigh in before starting.

--

I've fully converted Gonzales to threaded inserts and barrelnuts. No more m4 tapped HDPE, yay. I did this for ease of maintenance more than strength; m4 straight into HDPE is probably stronger with a long enough bolt. I had to make 18 inserts and 8 barrelnuts and work around my own build tolerances from 11 months ago. Slow process!

Pic spam (although when bolted up the only visible difference is the change of bolts...)

Most of the inserts are m8 external and m4 internal:

I experimented with m6 external for the top and bottom panels to try and save a few grams. These aren't very strong but they shouldn't need to be (typical 9t drill pinion for scale):

The chassis as of this evening:

What's in those pics weighs 403g. I don't know what it weighed before, probably 20-30g less. I'm hoping with the other changes I still have enough left to stiffen the wedge.

Comment

-

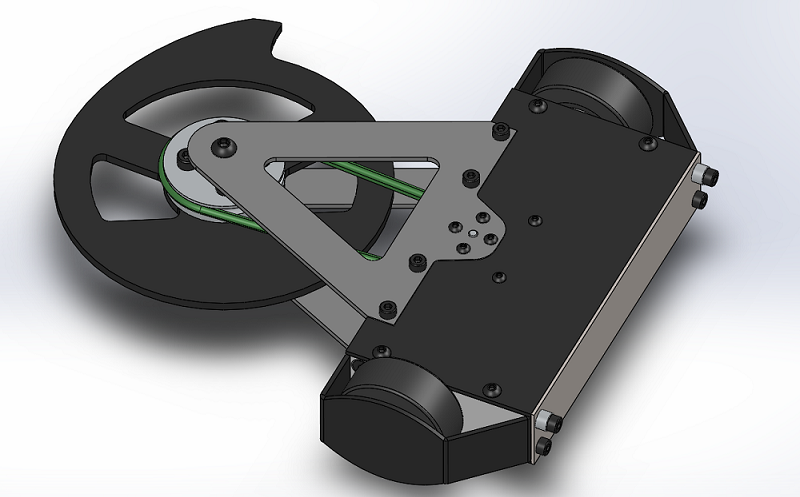

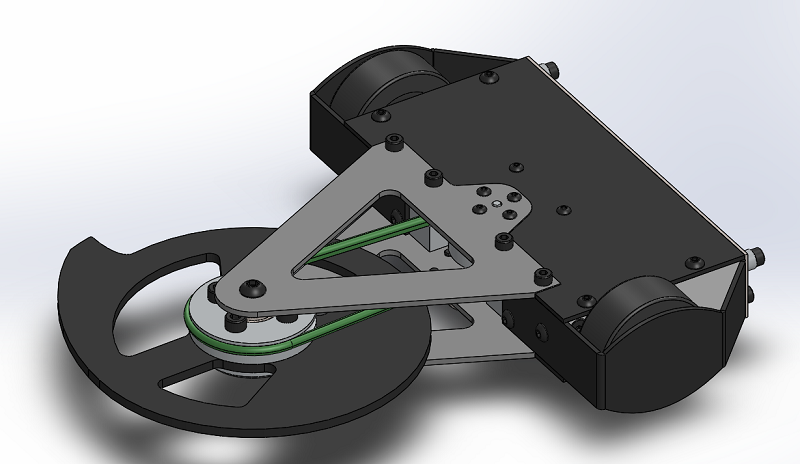

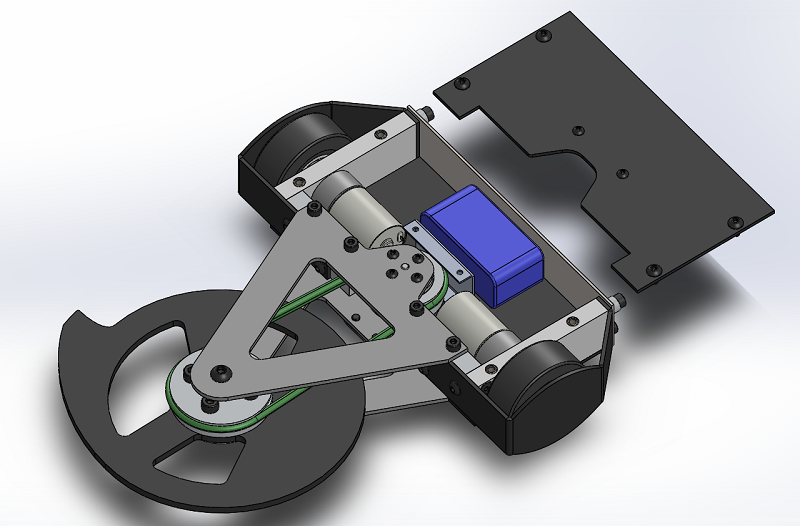

Spent the day in CADland instead of the workshop today.

It weighs 1320g as pictured, so lacking ESCs, rx and general wiring.

edit: no it doesn't! I'm new to Solidworks and I wrongly assumed it'd assign a realistic material density to bolts taken from its own library. After correcting I have roughly 90g left for ESCs and wiring. Should still be quite doable, but tighter than anticipated.Last edited by Ellis; 1 August 2014, 23:17.

Comment

Comment