Excellent. Last 2 questions for now...

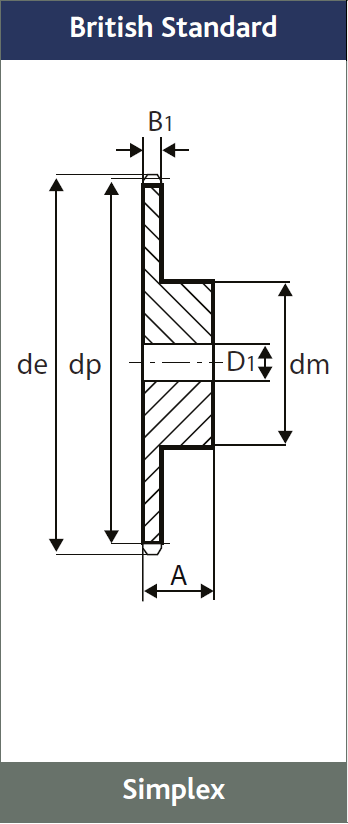

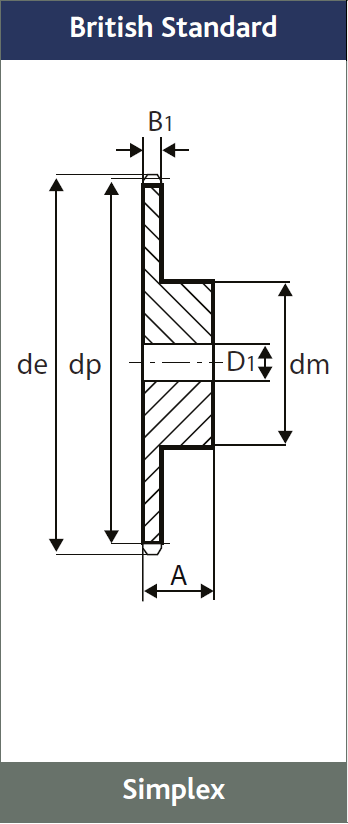

1: Should I use 11T Steel Simplex sprockets (this one):

Or am I overthinking it and should use Platewheel Simplexes for all three parts of the mechanism? I ask because I feel like the "dm" bit on the 11T would be a bit too large for a 12mm steel shaft with key to go through and could lead to breaking said sprocket without so much of me breathing on it.

And 2, would it help for me to use a couple of Shaft Collars to keep the shafts from sliding out on use?

Once again I apologise for all the questions, just that I've been sitting on this project for so long, I just wanna get this right...

1: Should I use 11T Steel Simplex sprockets (this one):

Or am I overthinking it and should use Platewheel Simplexes for all three parts of the mechanism? I ask because I feel like the "dm" bit on the 11T would be a bit too large for a 12mm steel shaft with key to go through and could lead to breaking said sprocket without so much of me breathing on it.

And 2, would it help for me to use a couple of Shaft Collars to keep the shafts from sliding out on use?

Once again I apologise for all the questions, just that I've been sitting on this project for so long, I just wanna get this right...

Comment