Long post follows!

Last year, I took my previous featherweight robot, Battleaxe (Build Thread) to FRA Featherweight champs at Insomnia 61. It did OK I guess for a 1st generation robot, but 722 eventually tore it a new one :/

The event taught me a lot, and highlighted that there were a number of design flaws that needed to iron out, and some of those couldn't really be sorted out without extensive changes. Hence I decided that rather than change Battleaxe (which will continue to run at live shows), I would rebuild entirely for a 2nd generation robot. Hence the new build, Broadax!

Conceptually, it's the same base design as Battleaxe is, in that it is an Axe/Hammer bot, and the general aesthetic remains the same, however I wanted to make several improvements to the weapon, armour, and drive that I couldn't otherwise do with the existing build.

Broadax-1.0 v72.png

October 2017

The build started properly around the time of Extreme Robots Gloucester last year. I had made the decision that this time, the robot would be fully brushless, for both drive and weapon. Parts were chosen and ordered, after a bit of research I started from the base of a drive system similar in specifications to 30haul, Charles Guans 30lb version of Overhaul. Whilst it's not exactly that now, this eventually ended up with me picking 4248 650kV motors coupled to 13:1 ratio planetary gearboxes. It's plenty torque-y enough!

We also had a cardboard mockup made for sizes to be worked out, as Broadaxs' footprint is quite a bit smaller than Battleaxes'

IMG_20171116_213839.jpg

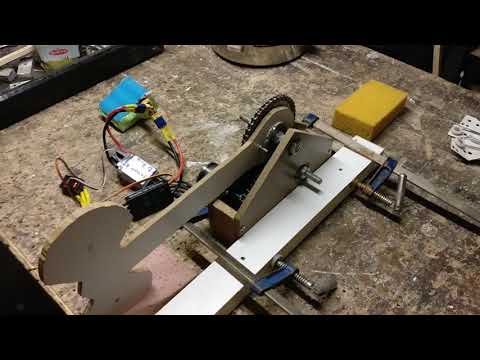

The weapon was also designed to be much bigger, heavier and made of stronger stuff than before (8mm Hardox 500 to be exact!), so I started to design the axe arm in CAD. The axe mechanism itself has ended up as a 5060 270kV motor coupled to a 22:1 chain/sprocket 2 stage gearbox. We made a plywood model to check for positioning and sizing, tested, and it delivered quite a kick! Back at this stage we had only tested it on 4s with a fake axe head (as the real one hadn't come yet) but it will eventually run on 7s. The tests are not videoed for that

November / December 2017

During this time, we were working primarily on our Beetleweight, SCD, so didn't really touch Broadax much over this time. We were however looking into CAD milling in our workshop rather than sending out to get the parts done externally. This ended up in the top and bottom of SCD being made successfully at home using our custom-made CAD mill, with the idea to also then use it for making Broadaxs' bulkheads. This turned out not to work in the end, but we hope it might be a path for the future.

January 2018 / early February 2018

This was where I turned things on their head a little. Up until this point, I had been working with Cardboard Aided Design, but I thought it's about time I actually learned proper Computer Aided Design, as some of the parts that Broadax needed wouldn't be possible to make at home (the Hardox armour for example). So I set to making the model in Fusion 360, and learning this from the ground up. It took some time, but as I had used Sketchup for Battleaxes' early design, I had some familiarity. This ended up with everything we needed nicely available in a 3D render, to the point that I was even able to use the viewer on iPad whilst in the workshop to check dimensions for some of the supporting parts.

IMG_20180303_161354.jpg

Late February 2018 / early March 2018

The crap weather kicked in, and it meant that getting to the workshop was not feasible (it's ~30 miles away from where I live and I can only get there on weekends). So more 3D modelling was done on those days that I couldn't leave the house. At this point, I had pretty much everything modelled the way I wanted it, so I started to send off for the parts. It was always the plan to get the axe and armour waterjet cut from Hardox, but due to the issues with the workshop mill, I also got the Aluminium bulkheads ordered in. All of this was ordered from KCut who did an amazing job, not only being spot on what I needed but it all got here in 2 days!

IMG_20180315_183116.jpg IMG_20180316_172621.jpg IMG_20180307_183950.jpg

Late March 2018

This weekend and last were intended for the build to be completed, now that we have all of the parts available, but the weather has scuppered the ability to do this. So it has been mocked (taped together!) to make sure everything works for fit, and so that I can at least work on wiring and other odd jobs before we bolt the whole thing together as soon as I get access to the workshop again.

IMG_20180317_153442.jpg

The aim is to get this finished and ready for Extreme Robots Manchester coming up at the end of April 2018, but it's all very weather permitting now at this stage!

Last year, I took my previous featherweight robot, Battleaxe (Build Thread) to FRA Featherweight champs at Insomnia 61. It did OK I guess for a 1st generation robot, but 722 eventually tore it a new one :/

The event taught me a lot, and highlighted that there were a number of design flaws that needed to iron out, and some of those couldn't really be sorted out without extensive changes. Hence I decided that rather than change Battleaxe (which will continue to run at live shows), I would rebuild entirely for a 2nd generation robot. Hence the new build, Broadax!

Conceptually, it's the same base design as Battleaxe is, in that it is an Axe/Hammer bot, and the general aesthetic remains the same, however I wanted to make several improvements to the weapon, armour, and drive that I couldn't otherwise do with the existing build.

Broadax-1.0 v72.png

October 2017

The build started properly around the time of Extreme Robots Gloucester last year. I had made the decision that this time, the robot would be fully brushless, for both drive and weapon. Parts were chosen and ordered, after a bit of research I started from the base of a drive system similar in specifications to 30haul, Charles Guans 30lb version of Overhaul. Whilst it's not exactly that now, this eventually ended up with me picking 4248 650kV motors coupled to 13:1 ratio planetary gearboxes. It's plenty torque-y enough!

We also had a cardboard mockup made for sizes to be worked out, as Broadaxs' footprint is quite a bit smaller than Battleaxes'

IMG_20171116_213839.jpg

The weapon was also designed to be much bigger, heavier and made of stronger stuff than before (8mm Hardox 500 to be exact!), so I started to design the axe arm in CAD. The axe mechanism itself has ended up as a 5060 270kV motor coupled to a 22:1 chain/sprocket 2 stage gearbox. We made a plywood model to check for positioning and sizing, tested, and it delivered quite a kick! Back at this stage we had only tested it on 4s with a fake axe head (as the real one hadn't come yet) but it will eventually run on 7s. The tests are not videoed for that

November / December 2017

During this time, we were working primarily on our Beetleweight, SCD, so didn't really touch Broadax much over this time. We were however looking into CAD milling in our workshop rather than sending out to get the parts done externally. This ended up in the top and bottom of SCD being made successfully at home using our custom-made CAD mill, with the idea to also then use it for making Broadaxs' bulkheads. This turned out not to work in the end, but we hope it might be a path for the future.

January 2018 / early February 2018

This was where I turned things on their head a little. Up until this point, I had been working with Cardboard Aided Design, but I thought it's about time I actually learned proper Computer Aided Design, as some of the parts that Broadax needed wouldn't be possible to make at home (the Hardox armour for example). So I set to making the model in Fusion 360, and learning this from the ground up. It took some time, but as I had used Sketchup for Battleaxes' early design, I had some familiarity. This ended up with everything we needed nicely available in a 3D render, to the point that I was even able to use the viewer on iPad whilst in the workshop to check dimensions for some of the supporting parts.

IMG_20180303_161354.jpg

Late February 2018 / early March 2018

The crap weather kicked in, and it meant that getting to the workshop was not feasible (it's ~30 miles away from where I live and I can only get there on weekends). So more 3D modelling was done on those days that I couldn't leave the house. At this point, I had pretty much everything modelled the way I wanted it, so I started to send off for the parts. It was always the plan to get the axe and armour waterjet cut from Hardox, but due to the issues with the workshop mill, I also got the Aluminium bulkheads ordered in. All of this was ordered from KCut who did an amazing job, not only being spot on what I needed but it all got here in 2 days!

IMG_20180315_183116.jpg IMG_20180316_172621.jpg IMG_20180307_183950.jpg

Late March 2018

This weekend and last were intended for the build to be completed, now that we have all of the parts available, but the weather has scuppered the ability to do this. So it has been mocked (taped together!) to make sure everything works for fit, and so that I can at least work on wiring and other odd jobs before we bolt the whole thing together as soon as I get access to the workshop again.

IMG_20180317_153442.jpg

The aim is to get this finished and ready for Extreme Robots Manchester coming up at the end of April 2018, but it's all very weather permitting now at this stage!

Comment