Also watch out for any small washers that are on the shaft and make sure that these go back in the places they are meant to!

Announcement

Collapse

No announcement yet.

[FW] Wedge Spinner in time for Robo Challenge champs!

Collapse

X

-

Thanks guys, will look into doing that once I receive the motor in the mail tomorrow and assess how it all goes together. Just got a quote back from kcut for the hardox discs and the price is much better than I expected! Happy days! I'm shopping around now to see if I can find a watercutting place with 15mm grade 5 titanium in stock to cut my bulkheads once they are finalised. I've tried a few places and I am awaiting replies, does anybody have suggestions?

Another question I have is about armour. How thick/what material are most using for armour? Im not sure if steel or titanium is better or other options. I know HDPE is popular, but I think I want to go the metal route.

My thoughts so far were: 5mm hardox wedge and some kind of steel of some kind of thickness elsewhere...

I'm also going to use these instead of bearings for the disc now:

http://simplybearings.co.uk/shop/Bea...duct_info.html

I noticed they have only got 2mm wall thickness though - will that be ok? I've been told that they are pretty durable compared to other options.

Sorry for all the questions... millions of thoughts flying through my head all at once..Last edited by Giles; 10 March 2016, 13:09.

Comment

-

15mm internal bulkheads that's even more over-engineered than something I would make! If you are set on that for some technical reason, add plenty of cut-outs to keep the weight down. I would seriously think about a tough aluminium like 2024 or 7075, which will be cheaper and easier to source. Titanium makes great armour but it is harder to fabricate and is by far the most expensive. The 8mm armour on my bots is considered stupidly thick and has held up well over the last three years.

that's even more over-engineered than something I would make! If you are set on that for some technical reason, add plenty of cut-outs to keep the weight down. I would seriously think about a tough aluminium like 2024 or 7075, which will be cheaper and easier to source. Titanium makes great armour but it is harder to fabricate and is by far the most expensive. The 8mm armour on my bots is considered stupidly thick and has held up well over the last three years.

You will get lots of conflicting answers about those bronze bearings. Personally, I have seen too many of them fail but it depends on how fast the weapon is spinning and how hard it hits. Since bronze bearings are so cheap, buy plenty of spares and consider them a consumable. You don't really need the Oilite bearings; they are meant for low maintenance situations and you are better off with a harder solid bearing and oiling it regularly. I would go for a thicker wall if possible, particularly as you have a stack of thin disks and if just one of them takes a high impact, its going to exert a huge amount of pressure on a small part of the bearing.

Comment

-

Haha, and there I was thinking "I hope 15mm is thick enough!" Say I dropped it down to 10mm thick, would aluminium still be good enough for the job? I would much prefer to work with alu than any other material, but I'm always concerned over it being strong enough.

Comment

-

It depends on how the parts are held together. Assuming you are drilling & tapping the aluminium for screws, I would keep it thick and add some cut-outs to reduce their weight. For internal parts that don't take direct impacts and need high tensile strength (the bulkheads supporting the weapon) 7075 or the similar Fortal aluminium alloys will do a great job. There is an even stronger alloy available in the UK but I can't recall the name - Mouldy used it in 722.

Comment

-

Hi all, thanks again for all the input! Today I made some good progress I think.

@Overkill I was intending to hollow out the bulkheads yes, and I have done so now!

@Maddox, that is good to hear, I think I have settled on the bronze bushings now, as I need to get the weapon blade cut very soon!

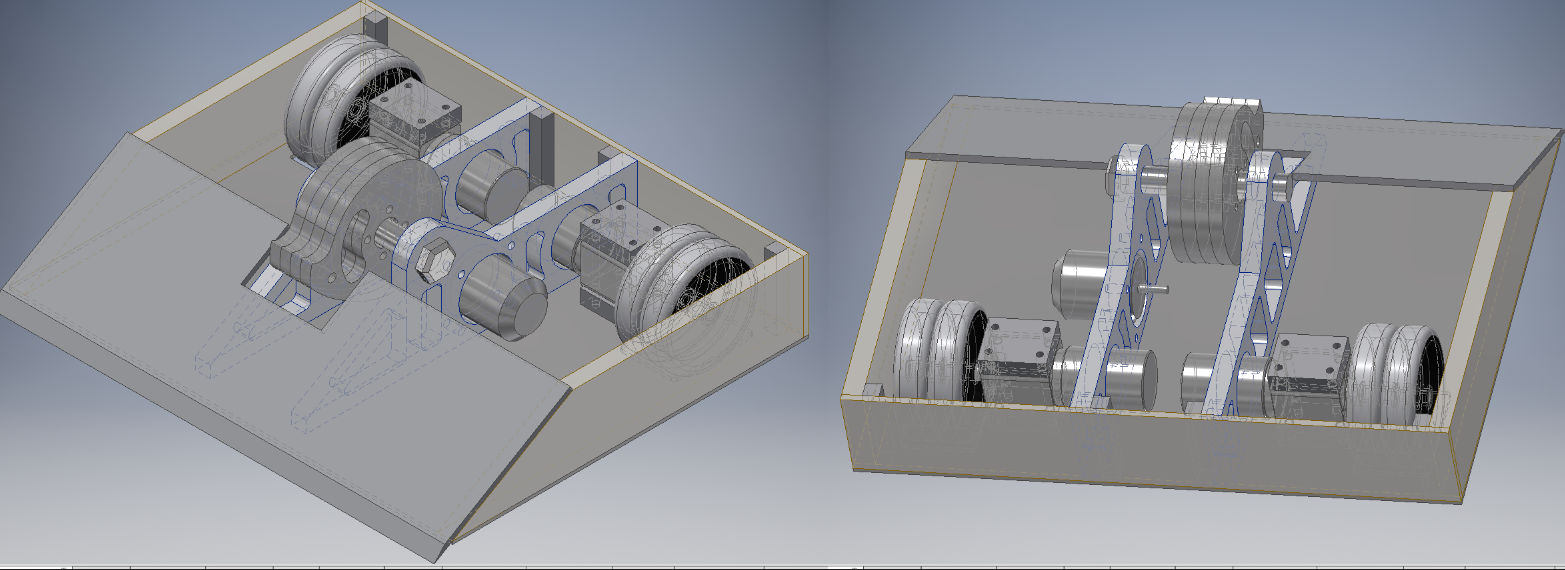

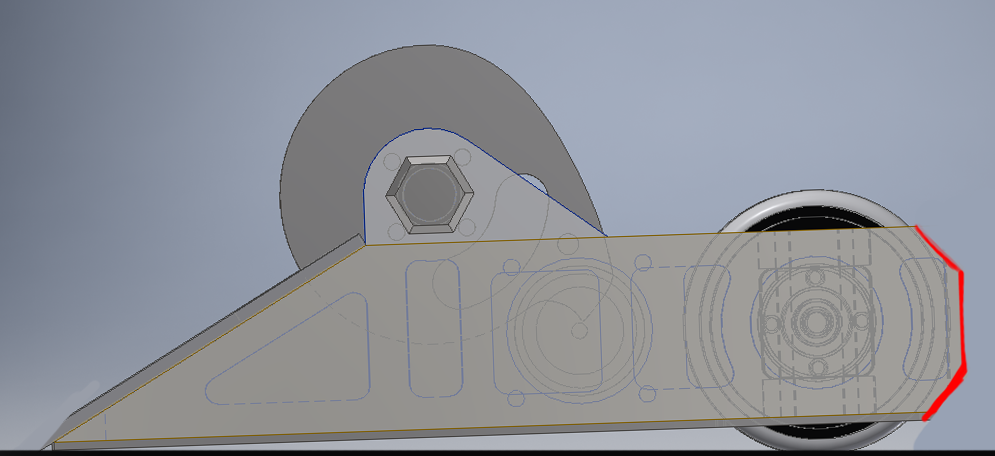

So tonight I was able to redesign the bulk heads and remove the other set of bulk heads that were no longer needed. I've also decided to ditch the belts and use the linear bearing mounts for hubs directly to the saturns.

As you can see, I've also inset the weapon drive motor, bringing it closer to where the pulley will be, and I have also offset the blade to one side so that I can side mount the pulley to it. The motors now sit ontop of solid nylon blocks to make them centered to the chassis, these will also be good shock absorbers.

Please ignore the gap in the front wedge being off center too

Next step for me is to angle the back of the robot and make it fit tighter to the wheels, so that when flipped it will still move (just about) to avoid count out.

I've found a supplier for 5mm grade 5 titanium & jet cutting, so I will probably be making all the armour from this and a 3mm plate for the bottom. I might still use a hardox wedge if I end up with enough weight left. Bulkheads will be 7075 alu.

Comment

-

I am starting to think about the circuitry in this and I have a question about fuses, on lights, and removable links.

Question 1:

Do I need a removable link AND fuse for both weapon and drive, providing they are two separate circuits? (I assume so?)

Question 2:

Can I use the fuse as the removable link? I want to use an automotive fuse, which would double up as a nice removable link.

Question 3:

What amperage must my fuse be rated at? The motors pull a fairly large stall current, so I'm not sure what my fuse should be rated at.

Question 4:

Rules state that I must have an "external LED" to show when the removable link is engaged. Again, Do I need two of these for weapon and drive circuits? and I assume "external" means you can just see it when the armour is on, and not actually sticking out of the robot.

Running a 6s lipo for weapon and a 5s for the drive wheels, so I would need two seperate circuits. Or do you guys advise I use a single big 6s and run everything from it?

Comment

-

You can definitely use the fuse as a removable link but you need a connector that isn't going to pop out from an impact. Most of the auto fuses bases will do in a pinch, but using something like an EC3 or XT-90 connector from Hobbyking will be stronger and more reliable. I cut the guts out of 200A fuses and solder them to the back of an XT-90 and its been very reliable.

You need one fuse and link per battery and to save weight and complexity, I would really try to go with just one pack. As long as the drive ESCs can take 22V, I'd run everything on 6S; its not that much of a jump from 5S as a percentage.

Comment

-

One thing I'm wondering with having one shared battery is the discharge rate, would it be able to keep up with 3 motors under a bit of strain? The batteries I have at the moment are 60C ones. Our ESC's could take 22V fairly easily, just need to fiddle around with the BEC components perhaps.

Talking of ESC's we've been using a new process for our prototype boards where you use glossy paper and an iron to transfer designs to copper. WAY easier than the UV light approach we've been using so far, I highly recommend.

Thanks for answering most of my questions for the fuses, I like the idea of soldering it to a XT90, as we're using XT60's for the ESC's and batteries. 200A was more than I expected, but I suppose that does add up if all 3 motors are stalled for some crazy reason.

ALSO THIS:

quote.jpg

50mm diameter, aluminium, £230.... I think not. It would be cheaper for me to buy a crappy chinese lathe, use it to build the part, and then throw it away.

For small machined parts like this, is there any cheaper options? Or can any body recommend a reasonable mini lathe to get? I'm sure this won't the last time I need something like this!

Last edited by Giles; 11 March 2016, 14:02.

I'm sure this won't the last time I need something like this!

Last edited by Giles; 11 March 2016, 14:02.

Comment

-

Looks like Harry can sort out that pulley for me then after talking further! Great

Had some parts waiting at home when I got back this evening, here is some of them!

20160311_220435.jpg

I know the 100A plush is a bit overkill, but I've used plush ESC's a lot in the past and I feel that they are a reliable choice and they are easy to reprogram if needed

Comment

-

A 200 A fuse is what I chose after blowing a couple of 80A ones, Its based on being less than the maximum current spike the batteries are rated for but more than the weapon ESC. For that battery in the photo, the fuse should be lower than the 165A peak the pack is rated for.

That pack is rated to supply 82.5A continuously and 165A for short periods (usually around 10 seconds). Most packs will get quite hot when running near their continuous rating and my guess is that your set-up will be pushing the pack hard if you powered everything from it. I would look at using around a 4AH pack rated for 65 - 130A to be sure you have enough current capacity for all the motors.

BTW: where did that hilarious pulley quote come from? I'd definitely take up Harry's offer.

Comment

Comment