I have not finished designing the weapon system fully yet. Yes they are 12g co2 tanks. i had a crazy idea for an on board fire extinguisher (still playing with that idea)

Announcement

Collapse

No announcement yet.

My First Build. ("Mischief" if that name isn't taken yet)

Collapse

X

-

when i designed that i was considering using a wheel to run along the inside of the drum. The reason i considered this is to give slip. If the weapon stopped suddenly without any slip i would risk damaging The weapon drive system (i think the motor would explode) though none of this is tested i will most likely build two or three options to figure out the best solution. Thanks for the tip about the belt drive I'm sure i would have run into that problem.Originally posted by Eventorizon View PostThis does look incredible! This is going to be a contender straight off the bat! (I looked at the other images and immediately thought over head bar spinner driven by a HK 40 (Or similar)... ouch!

I only see one issue.

http://s1177.photobucket.com/user/Ra...ml?sort=3&o=25

Top left hand view in that image, I take it that shows your belt set up? If so I doubt that will work. The area of contact to your rive pulley is so small that even if the belt is perfectly tight you will get slippage or the belt might pop off completely. if you get a longer belt you can use an ideler wheel to bring the belt further round on one side of the pulley, giving you more contact and reducing the risk of loosing drive. Hope that helps.

Comment

-

Ever notice that maybe you have been doing things totally incorrectly? well i did this morning...

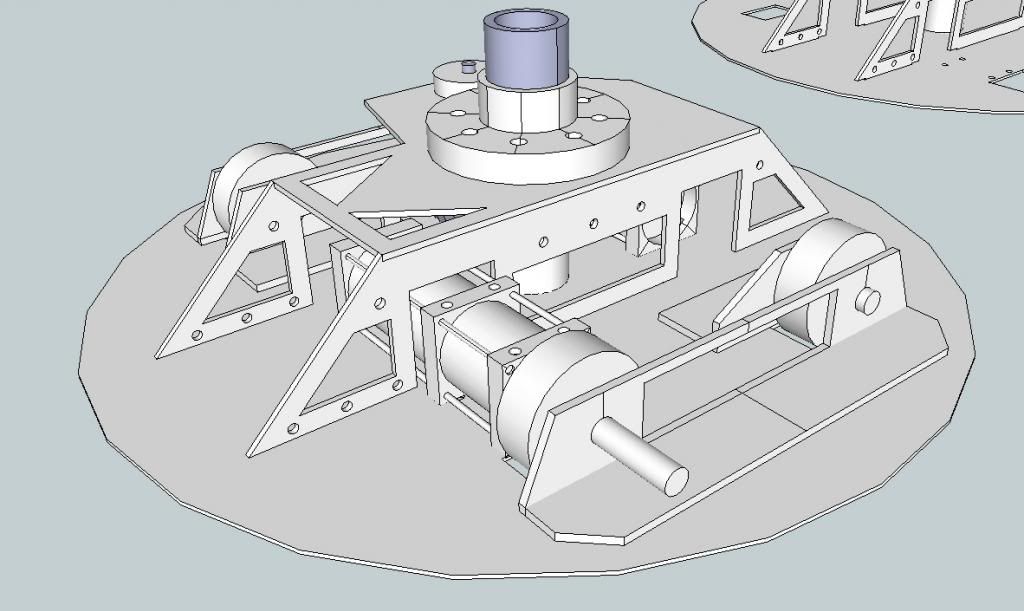

Now i am sure to go with a full body spinner i figured a much better way to build the robot.

This new build design will allow for extra battery packs to be added if required.

I will also be able to remove motors quickly if they are damaged.

http://s1177.photobucket.com/user/Ra...build.jpg.html

Comment

-

If you are serious about a rebuild, you need not design it for extra packs to be added. Designing it to accept one known configuration and optimising is better for that kind of machine. Now we are allowed 12S lipos you could design it for two 2650mAh 6 Cell packs (Wired in series and used as a pair) knowing that it will always work and and always fit.

If you want to be able to change it, make the head adjustable so that you can switch between something that cuts, something that clobbers and something that lifts (Or anything really). That is better far better (IMO) than messing with your internals.

Comment

-

I'm after a little advice i can foresee have a big problem with radio interference. This robot will be a full body spinner and i am pretty sure that i may have to try many aerial / radio systems.

Basically i am just wondering if anyone has had similar problems or knows of a good salutation before i invest in many different types of RC systems.

Any advice would be useful.

Comment

-

I doubt you will get interference or a blocked signal even with a full body spinner. LS4 has no issues with normal spektrum transmitters and receivers. If you are that worried you can get receivers designed to go inside all carbon fibre aircraft (Carbon fibre blocks 2.4Ghz).

For a long time we couldn't control Binky with its 2mm armour on but it turned out that it was a combination of 2 BECs, and a crap orange receiver that were doing us in. With 1 BEC and a genuine spektrum receiver, I had control of Binky from over 30m away.

Comment

-

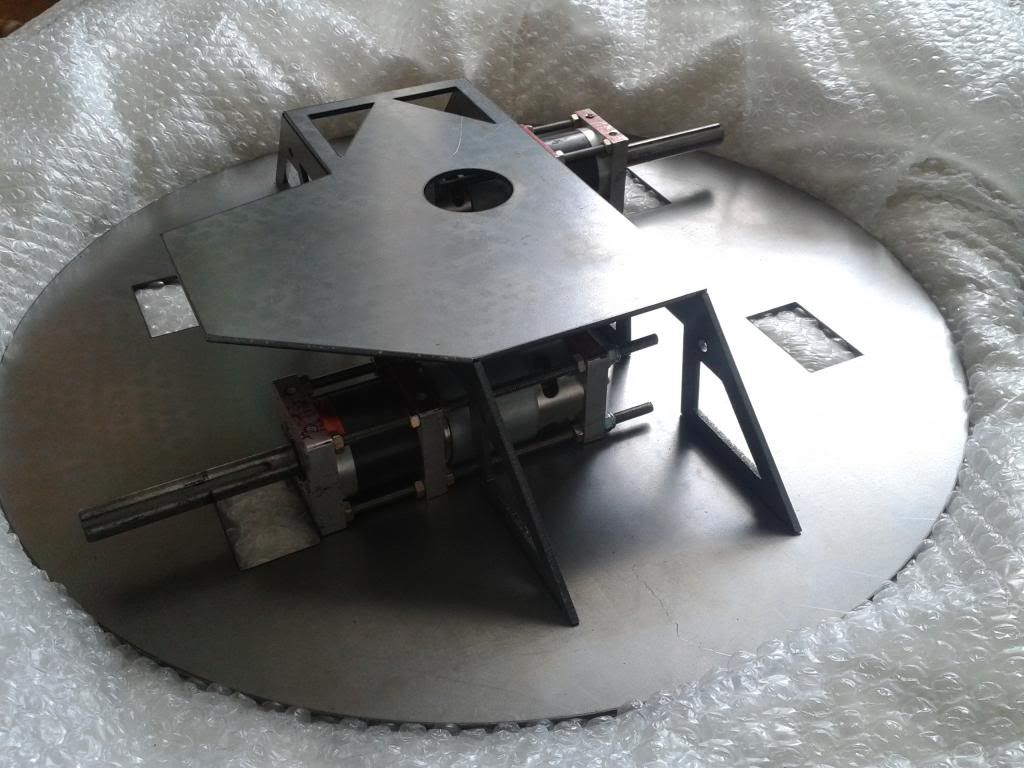

The new steel arrived today but it's very wrong due to my mistakes when converting from sketch up to draft sight... DERP!.

http://s1177.photobucket.com/user/Ra...tml?sort=3&o=7

Also 4mm steel is way to heavy.

This is just the base plate and weighs in at 5kgs.

http://s1177.photobucket.com/user/Ra...tml?sort=3&o=6

Looks good though and i was able to place some parts just to test fit.

http://s1177.photobucket.com/user/Ra...tml?sort=3&o=1

http://s1177.photobucket.com/user/Ra...tml?sort=3&o=4

http://s1177.photobucket.com/user/Ra...tml?sort=3&o=5

Comment

-

Looking really nice

I would be a bit worried about that base. It must be heavy and the cads dont show it being very well braced.

I had a 3mm front scoop on my feather and it was reasonably braced and its bent to hell after an event.

I will recommend people and in return could you mention where you got the steel cut?

Kenny, not sure he is about robot wise but he is a working freelance engineer

http://www.fightingrobots.co.uk/members/755-kenny

Famous maddox is the guy to go to for random specialties like gearboxes and rams

http://www.fightingrobots.co.uk/members/1160-maddox10

But there is countless people on this forum who have lathes and some one may pop up and offer to help you out or recommend someone else.

Comment

-

In the last picture it weighs almost 5kgs (Chassis and drive motors) I understand it may still need bracing but for now i need to get most of the main parts fitted correctly and working, then i can work out how much weight i have to play with for extra bracing.

I found this ebay shop that will cut steel to your shapes and sizes. i just give them a DXF file i made in DraftSight. They seem to get the parts cut and shipped really quickly too.

http://stores.ebay.co.uk/gdiproducts...p2047675.l2563

Comment

Comment