Hopefully the name hasn't been used previously.

So I was calling the robot TCOB but it was hard to say and really didn't make much sense to me

After Colchester the build diary is more a rebuild diary

After stripping the robot down I found a bad connection on one of the TZ85's that was causing some drive issues. Lack of ground clearance on the arena floor (especially after those heavies had chopped it up) gave control issues. The brass inserts in the GR01 were pulling out. Finally the axe stopped working because the grub screws came loose!!

The internal design caused finding these issues tricky - time for a rethink

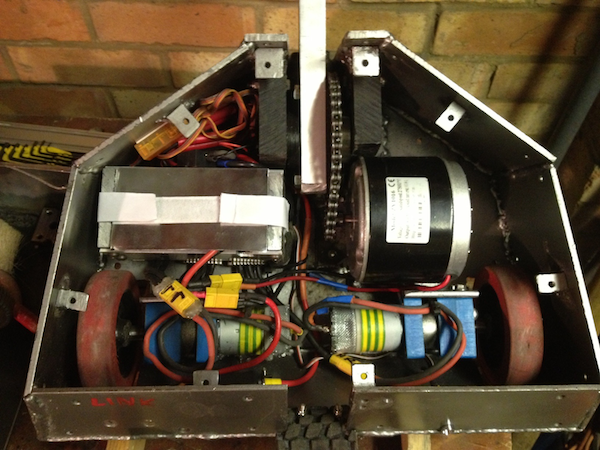

So this is a rough layout of the new internal design

- replace the 2 GR01 driving the axe with a scooter motor

- lighten the frame for holding the axe

- put the electronics together and rewire

- mount the GR01 on plates inside that allow easier release. Drill the plates to accept GR02's for the future (though I now will have a couple of spare GR01 boxes)

So I was calling the robot TCOB but it was hard to say and really didn't make much sense to me

After Colchester the build diary is more a rebuild diary

After stripping the robot down I found a bad connection on one of the TZ85's that was causing some drive issues. Lack of ground clearance on the arena floor (especially after those heavies had chopped it up) gave control issues. The brass inserts in the GR01 were pulling out. Finally the axe stopped working because the grub screws came loose!!

The internal design caused finding these issues tricky - time for a rethink

So this is a rough layout of the new internal design

- replace the 2 GR01 driving the axe with a scooter motor

- lighten the frame for holding the axe

- put the electronics together and rewire

- mount the GR01 on plates inside that allow easier release. Drill the plates to accept GR02's for the future (though I now will have a couple of spare GR01 boxes)

Comment