Well this was Spur. It was my first featherweight and in general happy with it

Good points

- Chassis was solid. It used 10mm HDPE but the corners were joined with angle iron and had a 3mm base. You didn't want to drop it on your toe!

- Traction. It used 4 drill motors with 100mm blue wheels with mountain bike tyre. The tyre had a nice open tread and wear rate was low

- Its a lifter and the linear actuator was very powerful

Bad points

- The wheels were exposed so vulnerable. It got slipped once landing on a wheel wrecking the gearbox

- Linear actuators have no give. So landing on the forks meant the forces had to go somewhere. Generally into bending the forks

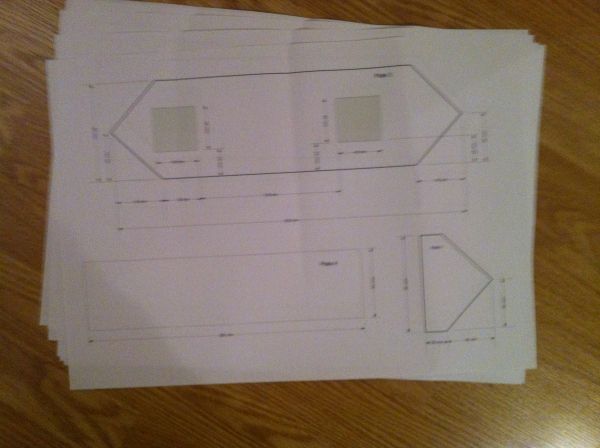

So after getting my axe robot into a working state, and learning a bunch from steel chassis bots, I have decided to build a new Spur imaginatively called Spur II

I wanted to keep the bot nice and small. This allows me to use weight in a more flexible manner.

Key objectives

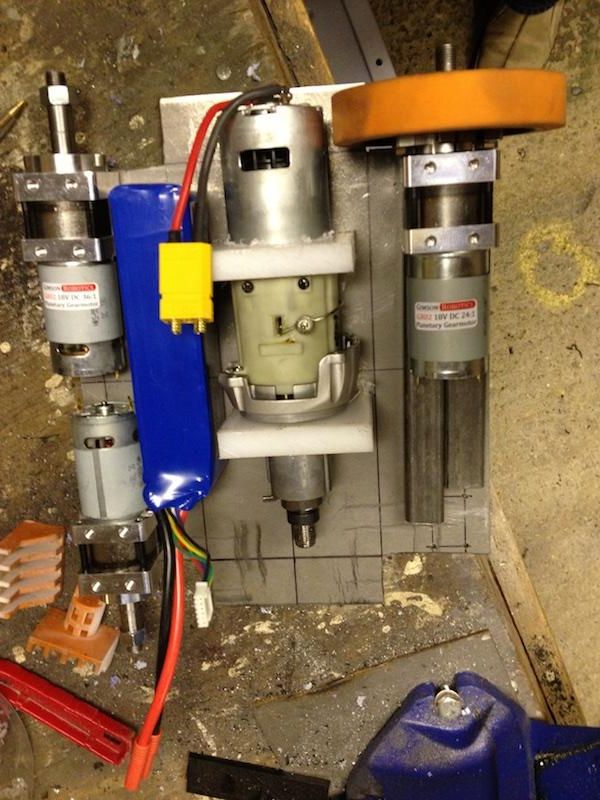

- good traction

- protected wheels

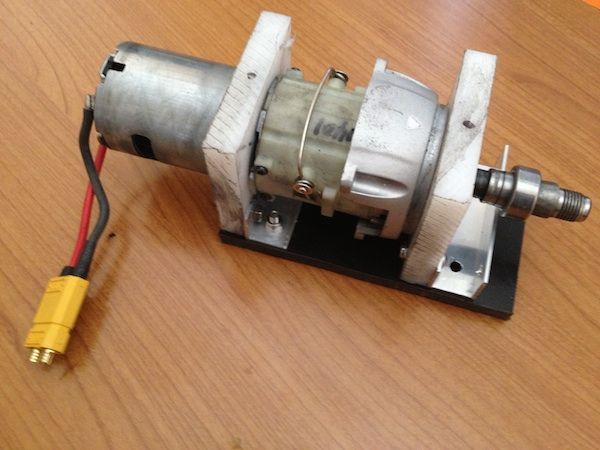

- strong lift but able to withstand shocks i.e. flips

- able to go full combat

Good points

- Chassis was solid. It used 10mm HDPE but the corners were joined with angle iron and had a 3mm base. You didn't want to drop it on your toe!

- Traction. It used 4 drill motors with 100mm blue wheels with mountain bike tyre. The tyre had a nice open tread and wear rate was low

- Its a lifter and the linear actuator was very powerful

Bad points

- The wheels were exposed so vulnerable. It got slipped once landing on a wheel wrecking the gearbox

- Linear actuators have no give. So landing on the forks meant the forces had to go somewhere. Generally into bending the forks

So after getting my axe robot into a working state, and learning a bunch from steel chassis bots, I have decided to build a new Spur imaginatively called Spur II

I wanted to keep the bot nice and small. This allows me to use weight in a more flexible manner.

Key objectives

- good traction

- protected wheels

- strong lift but able to withstand shocks i.e. flips

- able to go full combat

Comment