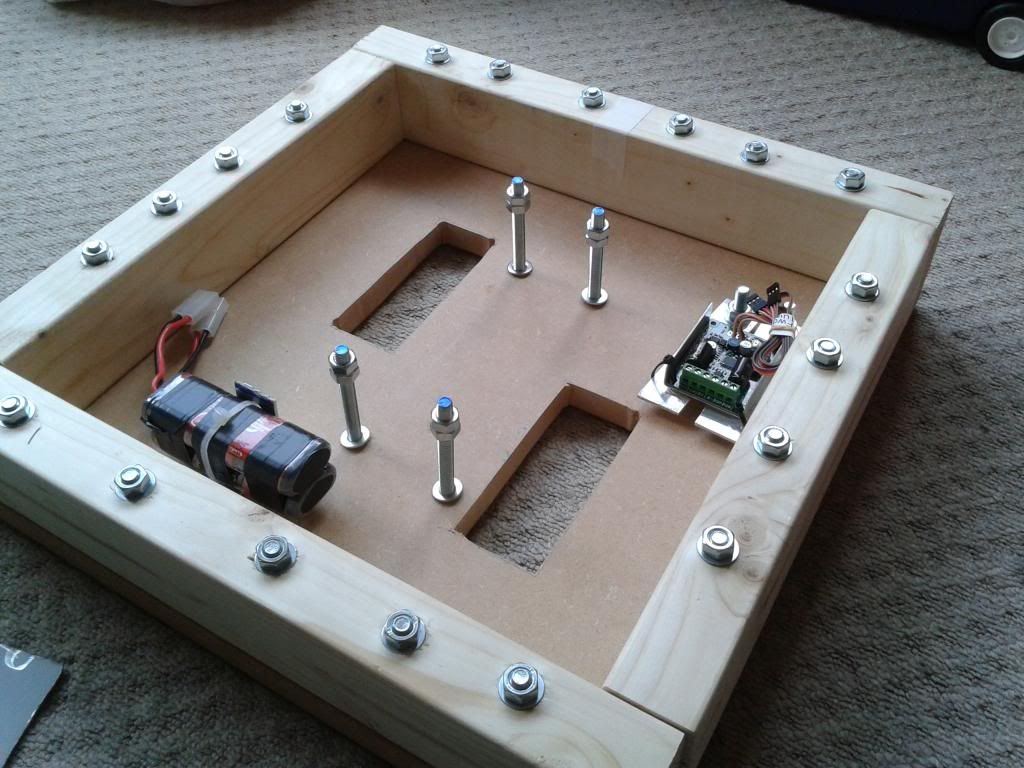

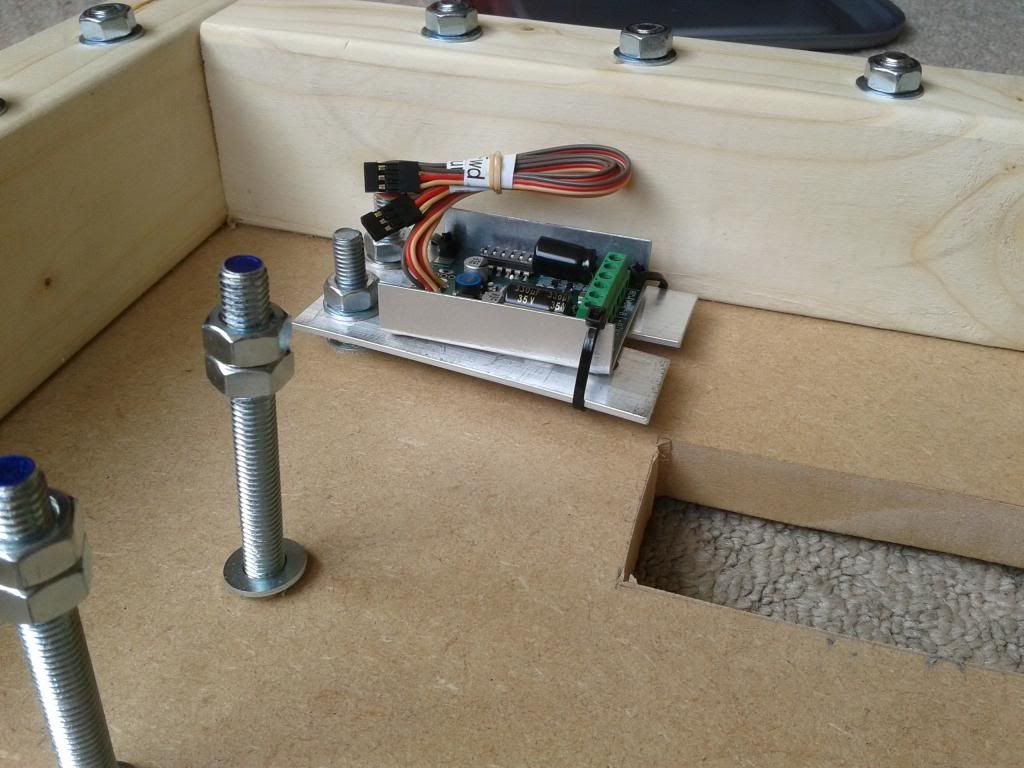

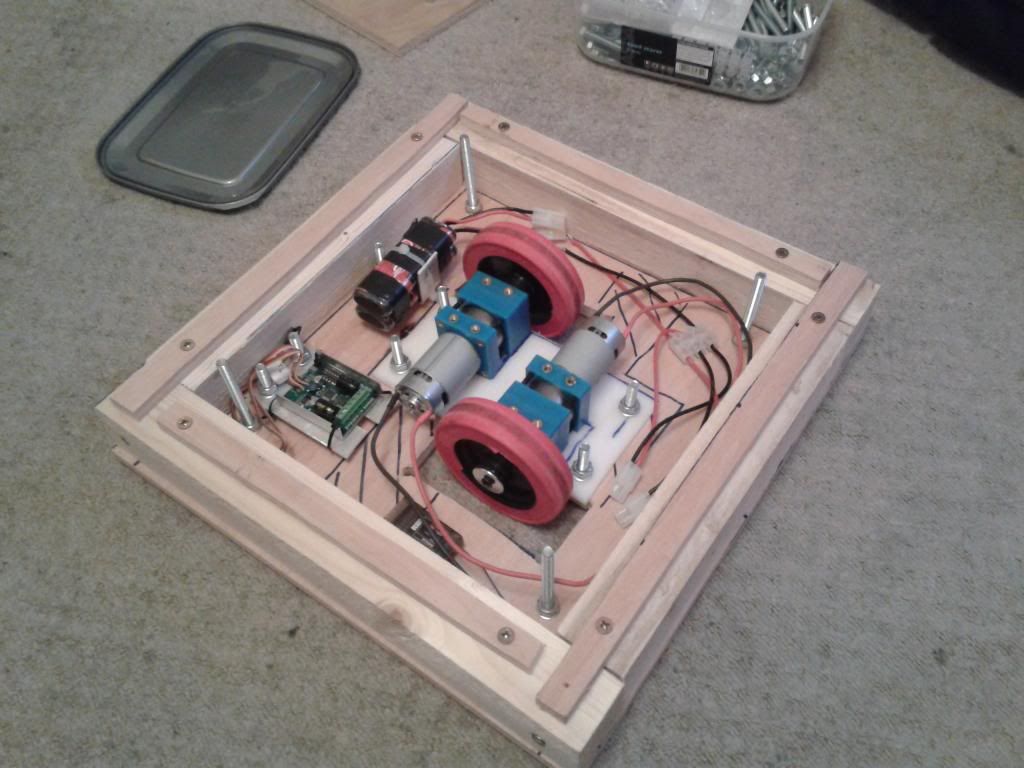

Some more pictures, I have some brackets that I've made but I've yet to pull it all together and get pictures of it all together. I'm basically waiting for another pack of the main bolts to turn up. It holds it all together but they'll be another fortnight or so.

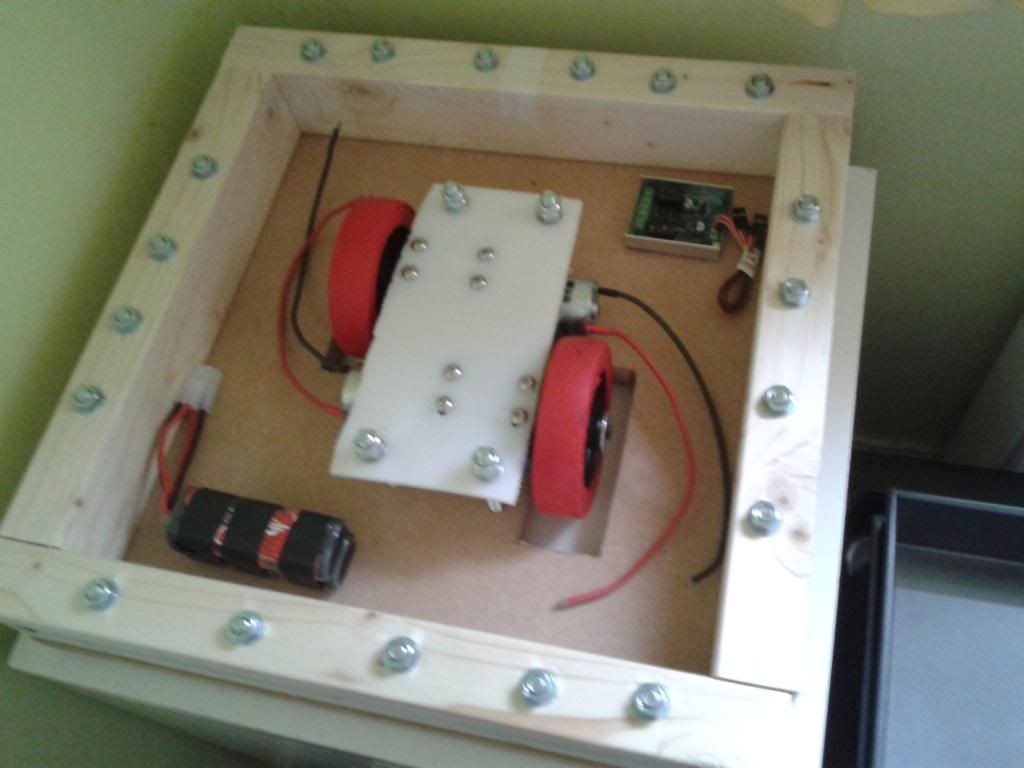

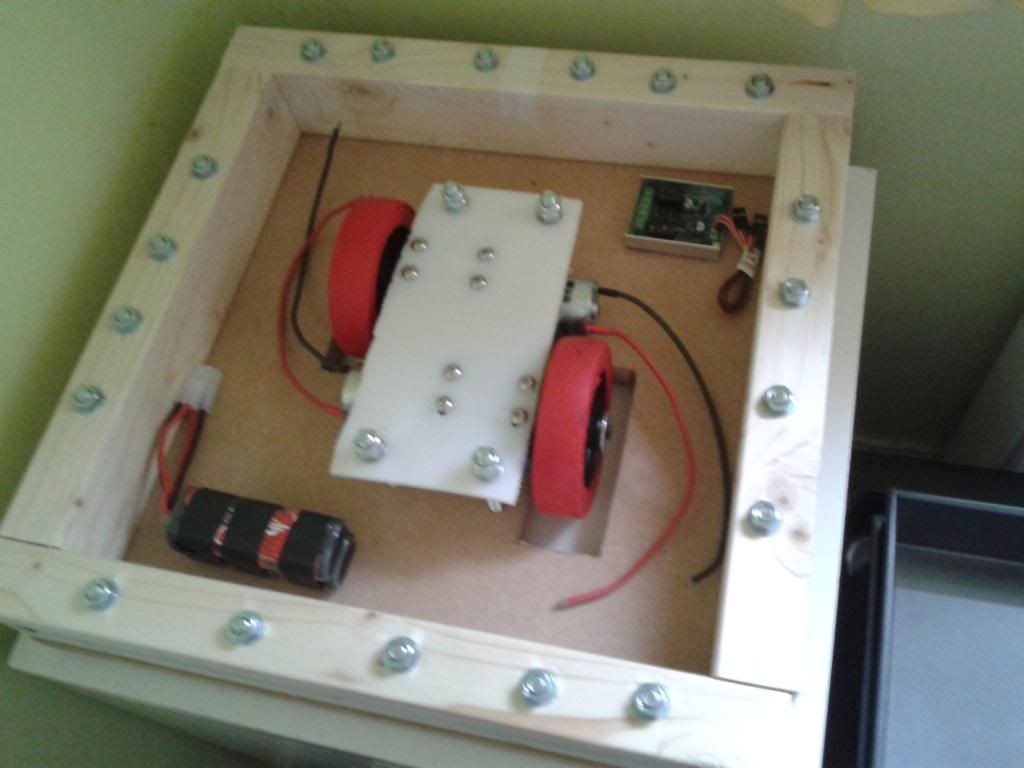

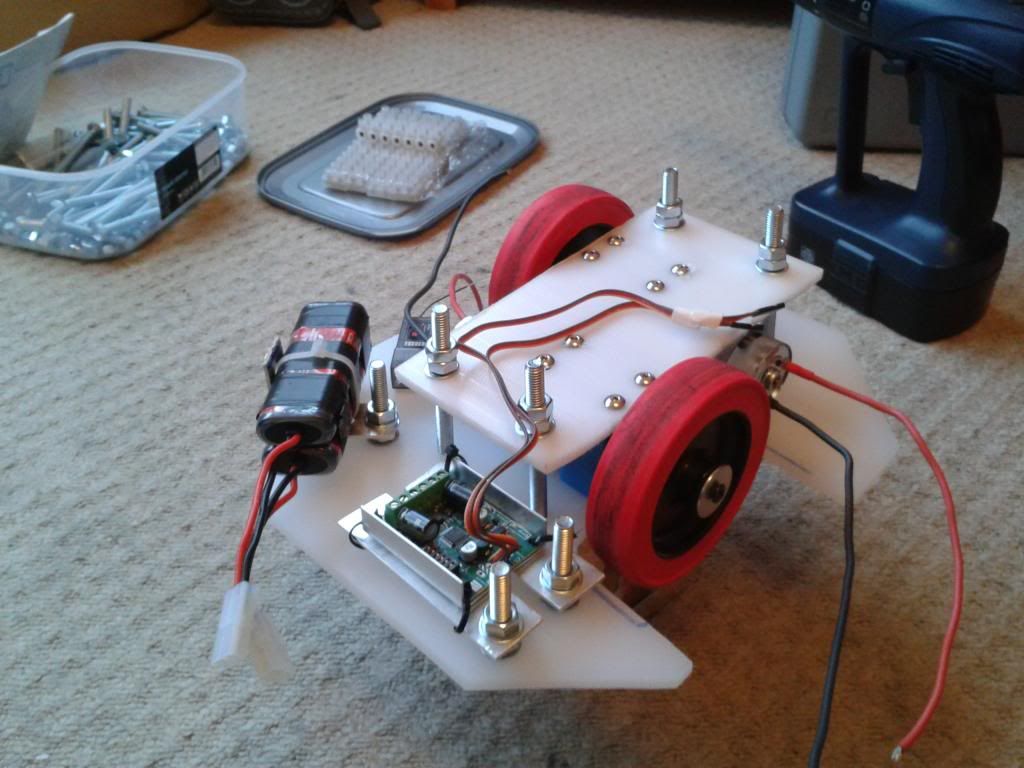

Just thought I would say the top panel isn't sat square in the second picture! When it's on properly it sits square and flush covering the whole top! Thinking about calling it Wabbajack after my favourite Skyrim weapon lol.

Just thought I would say the top panel isn't sat square in the second picture! When it's on properly it sits square and flush covering the whole top! Thinking about calling it Wabbajack after my favourite Skyrim weapon lol.

Comment